Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the construction industry. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising Additive Manufacturing Startups.

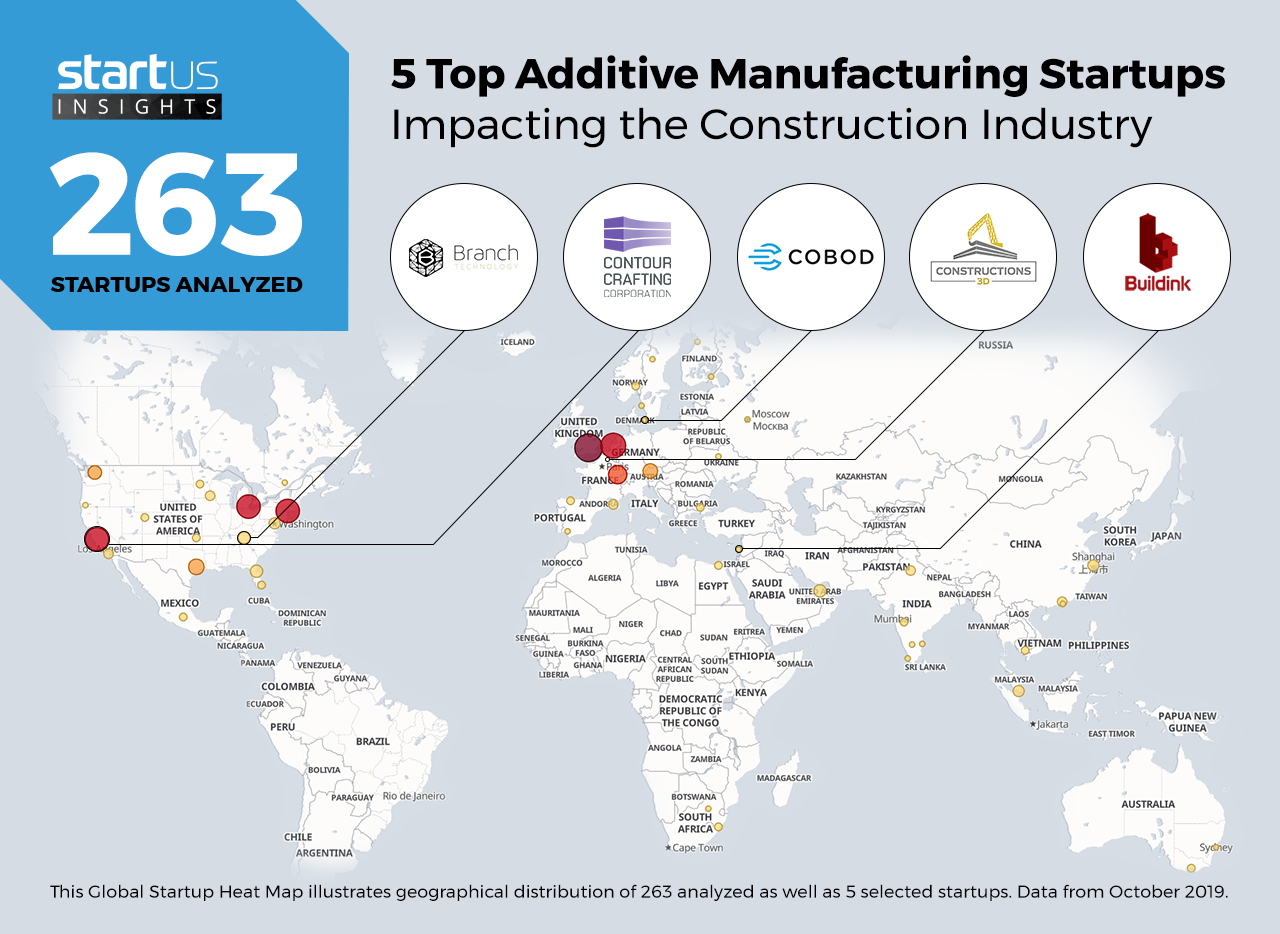

Heat Map: 5 Top Additive Manufacturing Startups

For our 5 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 263 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Buildlink – Printing Concrete

There are three big reasons for printing concrete using additive manufacturing techniques, also known as 3D printing: (1) It can be printed at low costs. (2) It can be created or printed significantly faster than traditional methods. (3) There is almost no wastage of raw construction materials. It is no surprise then, that there are many applications for 3D printed structures. From large scale buildings and buildings for war-torn regions to printing bridges and benches, companies are steadily adopting additive manufacturing technologies in construction. Lebanese startup Buildink develops concrete 3D printers capable of creating single-story homes in just one week. They use their proprietary-engineered and environmentally-friendly concrete mix in their projects. Their printers enable significant savings in time, construction costs, and logistics costs.

Branch Technology – Printing Walls

The major reason for 3D printing walls lies in one word: resilience. The walls built with traditional techniques are known for showing deficiencies – cracks form over time, water seeps through the walls, and even the steel slowly rusts. Additive manufacturing technology has the ability to build customized walls or wall panels which face none of these issues. The US-based startup Branch Technology develops large scale freeform 3D printers, offering solutions from design to construction. Their patented 3D printing process called Cellular Fabrication, or C-Fab, allows materials to solidify in open space creating a cell-like matrix in virtually any shape or form. Their technology opens the door for design-centric architecture.

COBOD International – Printing Small Scale Buildings

While large-scale 3D printed buildings are still something to expect in the near future, the same cannot be said for smaller 3D printed buildings. Many companies are realizing significant savings in time and resources for their clients by constructing small-scale buildings using additive manufacturing techniques. Danish startup COBOD International develops solutions with the aim of fully automating the construction process by designing robotic printers and automating processes for the building site. They use recycled materials to create a concrete mix enabling further reduction in resources required for construction.

Constructions 3D – Printing Large Scale Buildings

3D printing buildings gets rid of current architectural constraints imposed on design and implementation. It allows for freeform, creative, and imaginative concepts while reducing costs on the human, ecological, energy, time, and financial aspects of construction. French startup Construction 3D develop 3D printers capable of printing buildings between 140m2 and 245m2 (1,500sq.ft – 3,000sq.ft). Their robotic construction arms extend up to 10m (32ft) with a full 360-degree radius of 9.5m (31ft). They aim to play a crucial role in the future of construction by completely rethinking the processes and materials involved during large-scale building constructions.

Contour Crafting – Contour Crafting Technology

Existing 3D printing technologies for construction are limited by their inability to scale up quickly. The majority of printers are suitable for small structures or medium-sized buildings. Contour crafting is a novel method of 3D printing, which significantly saves time and resources compared to other 3D printers while being capable of creating much larger buildings. The US-based startup Contour Crafting develops a new kind of large, semi-autonomous 3D printer called the Contour Crafter. It is placed around the foundation laid for the building with a 3-dimensional axis. The special tracks which the robotic arms sit on form axis 1. The 6m (19.5ft) height of the robotic arms forms axis 2. And these two arms are connected at the center with a crossbeam, creating axis 3. With raw material added to the printer, construction happens layer by layer, completing a house in a matter of days.

What About The Other 258 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 startups showcased above are promising examples out of 263 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.