Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for Industry 4.0. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising metal additive manufacturing startups impacting industry 4.0.

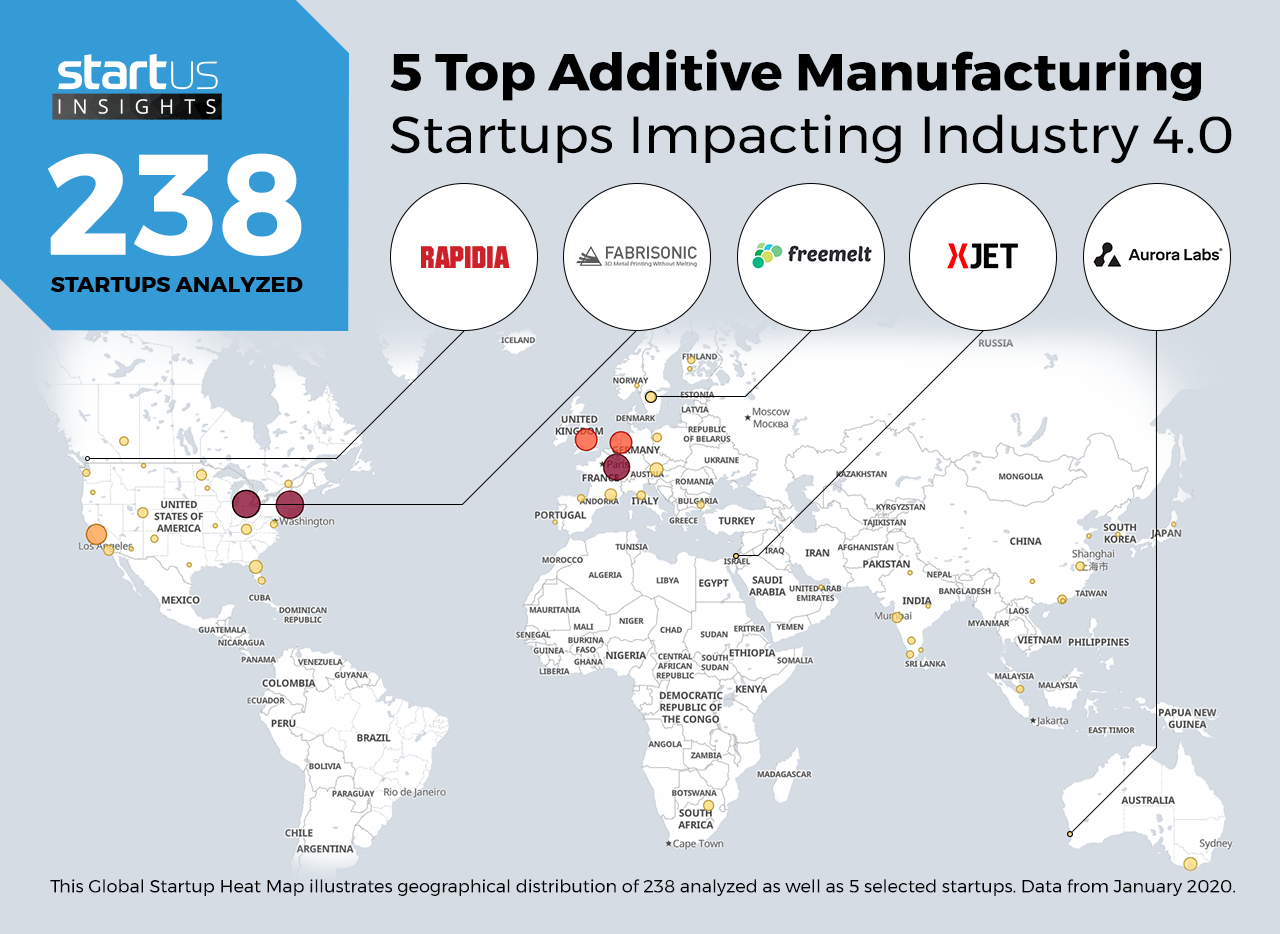

Heat Map: 5 Top Metal Additive Manufacturing Startups Impacting Industry 4.0

For our 5 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 238 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Freemelt – Open-Source Metal Additive Manufacturing

Many companies that develop metal-based additive manufacturing solutions do so behind closed systems that run on proprietary and restricted software systems. The availability of open-source systems in additive manufacturing of metals ensures an increase in the adoption of 3D printing at a much larger scale.

Swedish startup Freemelt develops Freemelt ONE, an open-source electron beam powder bed fusion optimized for the research and development of materials. The open-source software provides high process temperature and high vacuum, enabling its use with a wide range of materials in a collaborative environment.

Rapidia – Water-Based Metal Additive Manufacturing

The conventional three-stage process of printing, debinding, and sintering used for metal printing uses binders that need to be removed after printing. The debinding process can take up to 50 hours and often requires treating the printed part with dangerous chemical solvents. Companies are looking for ways to reduce the time needed for this process and have started using water to print metals.

Canadian startup Rapidia develops a proprietary water-based process to 3D print complex and strong metal parts in a 2-step process. The debinding step is completely eliminated by making use of a water-based metal paste, reducing the time and resources involved in the overall production process.

Aurora Labs 3D – High-Speed Metal Additive Manufacturing

Currently, powder bed fusion methods for metal printing use either a laser or electron beam to melt and fuse the material powder together. Direct metal laser melting (DMLM), a type of powder bed fusion process, uses lasers to melt ultra-thin layers of metal powder to build a 3D object. One of the drawbacks of using DMLM is its relatively slow speed and higher power usage.

Australian startup Aurora Labs 3D uses a patented multi-layer concurrent printing technology to increase the speed of the DMLM method by simultaneously combining powder coating and additives in one sweeping movement across multiple layers. Their Rapid Manufacturing Printer-1 can print up to 350kg of material every day.

XJet – NanoParticle Jetting Technology

Binder jet additive manufacturing, also known as powder bed and inkjet printing, has a broad range of applications and is used widely for making production-ready parts. Binder Jetting, like other metal additive manufacturing technologies, produces parts that require post-processing that requires more time than it takes to print the part.

Israeli company XJet develops a proprietary NanoParticle Jetting technology for 3D printing metals. These printers provide the versatility of inkjet-based additive manufacturing and use nano-sized metal particles, suspended within a liquid formula, that is later deposited onto the supporting material for printing. This process produces high-quality parts with complex geometries and with minimal post-processing tasks.

Fabrisonic – Hybrid 3D Printing

Industry 4.0 companies are exploring the possibilities of combining the additive and subtractive (CNC milling) technologies in a single machine. This hybrid manufacturing approach maximizes the utilization of the already installed subtractive manufacturing machines.

The US-based company Fabrisonic develops an ultrasonic additive manufacturing technique that combines a unique room-temperature metal deposition process with traditional CNC milling. They have integrated an ultrasonic ‘print head’ into a 3-axis mill to create a hybrid additive-subtractive process.

What About The Other 233 Additive Manufacturing Startups?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 startups showcased above are promising examples out of 238 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.

![Additive Manufacturing Technologies: 10 Emerging Innovations [2025 & Beyond]](https://www.startus-insights.com/wp-content/uploads/2024/10/Additive-Manufacturing-Technologies-SharedImg-StartUs-Insights-noresize-420x236.webp)