Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the manufacturing industry. This time, you get to discover 5 hand-picked on-demand manufacturing solutions.

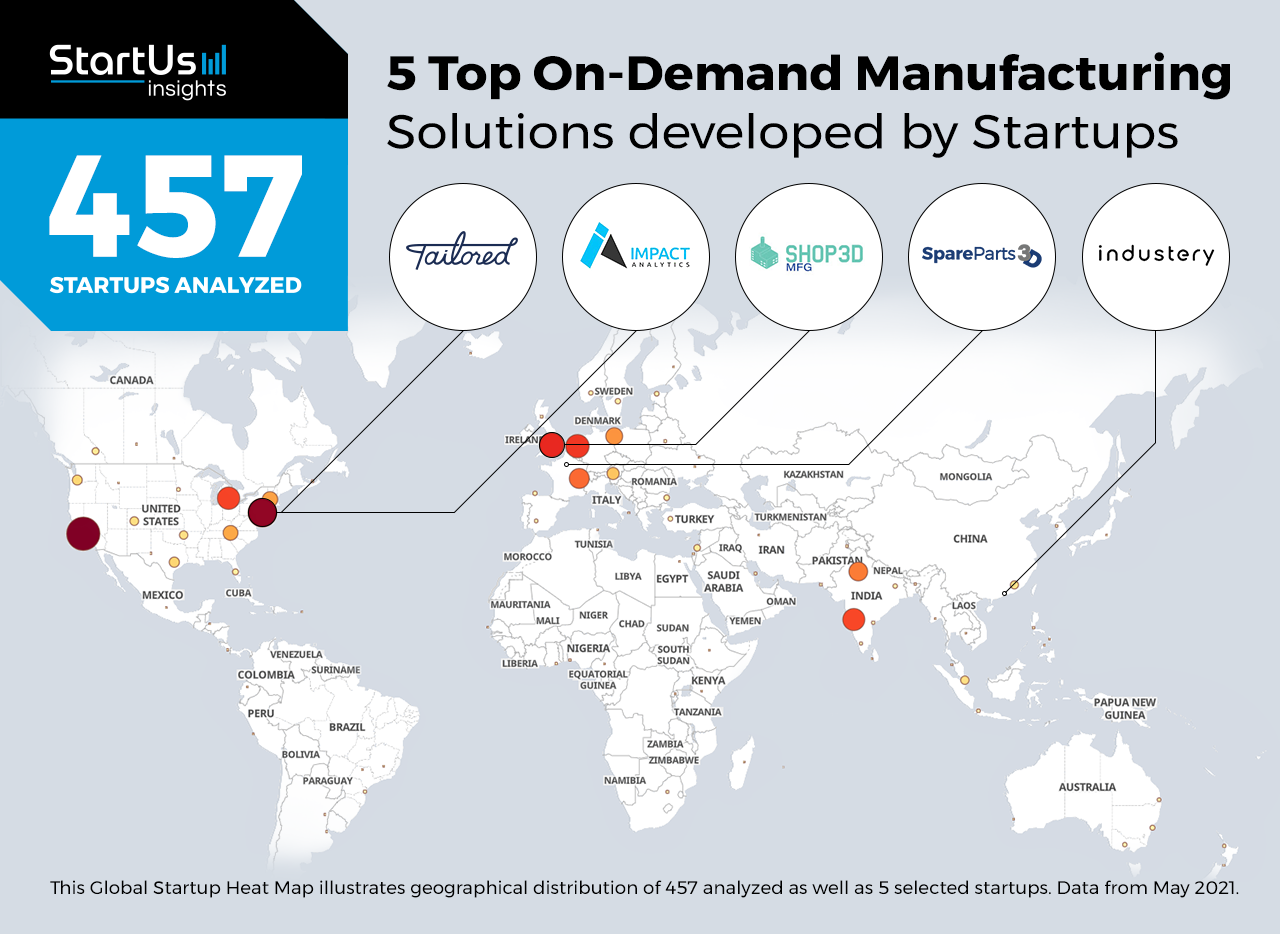

Global Startup Heat Map highlights 5 Top On-Demand Manufacturing Solutions out of 457

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 457 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 on-demand manufacturing startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 452 on-demand manufacturing solutions, get in touch.

Tailored Industry manufactures Zero-Waste On-Demand Knitwear

On-demand manufacturing eliminates the risk of product pileup prevalent in just-in-case manufacturing models. This, in effect, allows manufacturers to reduce inventory management costs. Moreover, since on-demand manufacturing is consumer-centric, parts are more likely to reach the market, decreasing wastage. Startups enable brands to incorporate on-demand manufacturing by developing solutions such as low volume production, and rapid prototyping.

US-based startup Tailored Industry offers zero-waste on-demand knitwear manufacturing using additive manufacturing. This allows the startup to reduce material wastage and improve inventory management. The startup’s on-demand app allows users to integrate their Shopify stores and launch their products. Once a customer orders a product, Tailored Industry manufactures and ships the final product to the customer, ensuring order fulfillment with low lead time. Further, the startup’s Partner Portal allows users to monitor their orders and manage product catalogs.

Spare Parts 3D digitizes Spare Part Inventory for On-Demand Manufacturing

Minimum order quantity, with high costs for the order, is the primary concern in conventional manufacturing. With advancements in computer-aided design (CAD) and 3D printing, startups extend production capabilities even for shorter runs. Also, on-demand manufacturing cuts product development and lead time, thus, reducing the time to market. For example, 3D printing allows designers to revise product designs without development-related concerns, enabling high-speed product development and mass customization.

Spare Parts 3D is a French startup that digitizes spare part inventory to enable on-demand and distributed production using 3D printing. The startup’s DigiPart IDENTIFY allows manufacturers to assess spare part printability and offers cost estimates. Plus, the DigiPart SCAN platform helps designers reverse engineer physical parts into digital counterparts using computer vision. Further, DigiPart PRINT connects manufacturers with global additive manufacturing suppliers to speed up production. The startup’s end-to-end additive manufacturing solution allows companies to eliminate obsolete parts and long-tail performance while improving customer satisfaction.

3DC offers Digital Inventory & Workflow Automation Software

On-demand manufacturing speeds up the production process as well as offers up-front costs for the manufacturers. Plus, the digital nature of the cloud-enabled on-demand manufacturing model allows manufacturers to identify data points throughout the production process. With the help of big data and analytics, startups are able to use this data to further streamline the production process and improve its efficiency.

British startup 3DC develops an on-demand manufacturing platform to automate digital inventory and workflow. The startup’s SHOP3D MFG integrates manufacturing execution system (MES) and product lifecycle management (PLM) solutions, allowing automatic tracking and inventory management. Also, the 3DC platform features instant pricing tools, customer management utilities, and price algorithms to find the right price for a product, among other solutions. In effect, the startup’s automation software allows manufacturers to track and manage their on-demand production, improving its transparency. Furthermore, the startup develops a 3D printing manufacturing addon, Shop3d.io, that automates manufacturing and order fulfillment.

Industery develops On-Demand Vacuum Casting Products

Apart from end-production support, cloud manufacturing is suitable for rapid prototyping and short-run productions. However, the choice of manufacturing technique varies based on the material and product. For example, while 3D printing is a practical choice to develop metal parts, startups also use computer numerical control (CNC) machining to manufacture them. The type of on-demand production differs based on the product specification and lead time. Therefore, startups improve conventional manufacturing methods to enable on-demand production.

Industery is a Chinese startup that offers low volume and on-demand manufacturing using vacuum casting. The startup allows manufacturers to upload their product’s 3D computer-aided design (CAD) file and select production specifications, such as material and finish. The startup also offers design for manufacturing (DfM) before confirming the production order. Industery’s manufacturing service has no minimum quantity, allowing companies to order exactly what they need. This reduces overall industry waste, capital investment, and the production period for their customers.

Impact Analytics provides an AI-based Demand Forecasting Solution

On-demand manufacturing follows market demand as the production commences after an order is made. Therefore, manufacturers and brands have to closely follow customer trends to understand their requirements and streamline production processes. With social media and other public platforms, startups collect critical customer data on products and services. Startups then develop forecasting models to predict the market behavior, allowing brands to change their production workflows proactively.

Based in the US, Impact Analytics is a startup that provides AI-based demand forecasting for manufacturing, retail, and consumer goods industries. The startup’s Forecasting-ADA leverages big data and uses large datasets from multiple clients to generate actionable business insights and demand forecasts. Additionally, the solution automatically adjusts inventory levels to accurately meet customer demand, helping on-demand manufacturers speed up production. Further, Impact Analytics’ forecasting algorithms quickly simulate what-if scenarios, allowing manufacturers to better understand market vulnerabilities and opportunities.

Discover more Manufacturing Startups

Manufacturing startups, such as the examples highlighted in this report, focus on spare parts management, demand forecasting, and digital inventory management. While all of these technologies play a major role in advancing manufacturing strategies, they only represent the tip of the iceberg. To explore more manufacturing technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Manufacturing Innovation Report to save your time and improve strategic decision-making.