Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the automotive industry. This time, you get to discover 5 hand-picked startups developing lean manufacturing solutions.

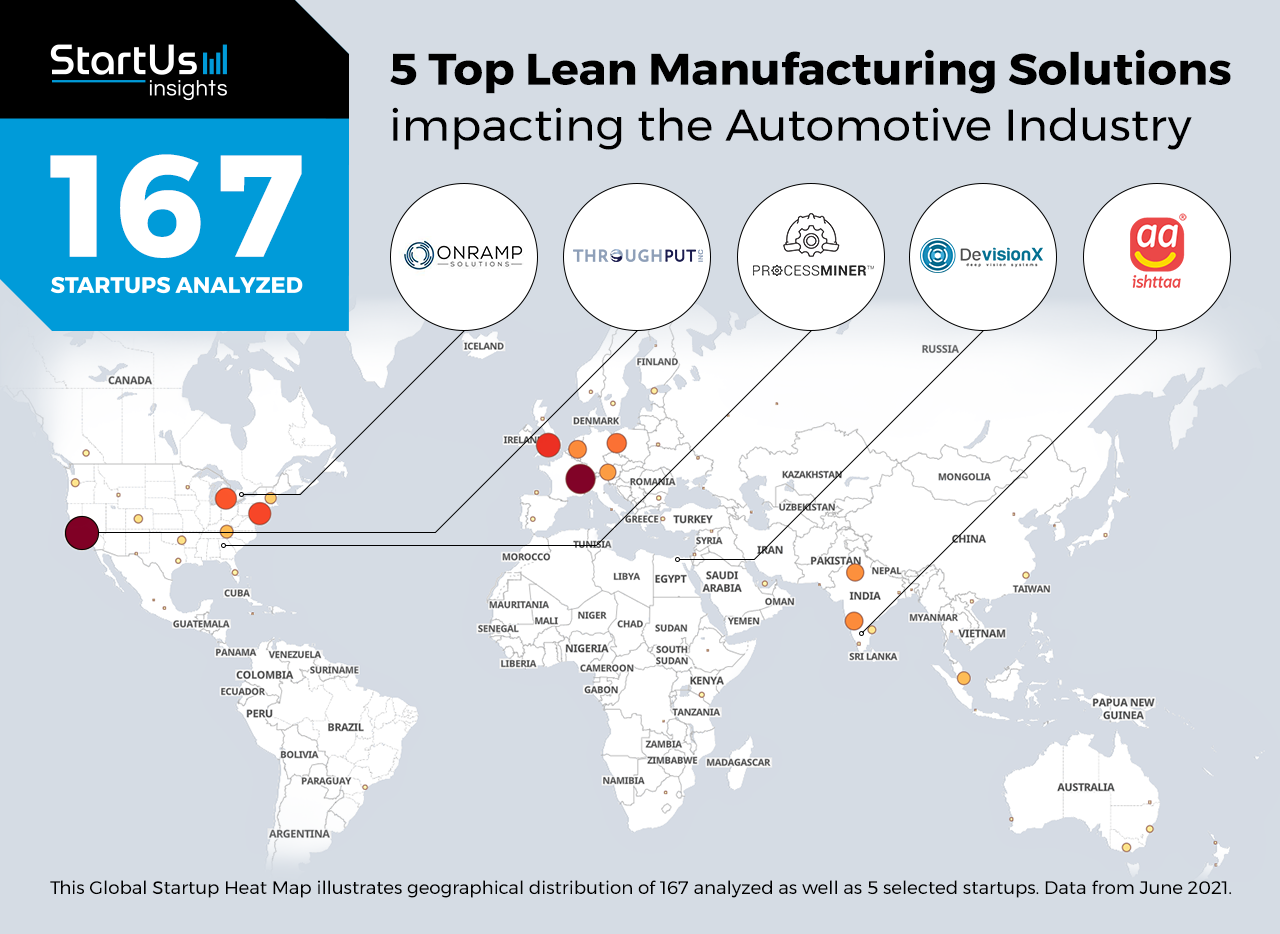

Global Startup Heat Map highlights 5 Top Lean Manufacturing Solutions out of 167

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 167 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 automotive startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 162 lean manufacturing solutions, get in touch.

ThroughPut automates Supply Chain Operations

The impact of Industry 4.0 on the automotive industry opens up new opportunities for manufacturers to integrate lean principles in their production workflows. This includes optimizing manufacturing for minimal resource wastage from design to production levels. From stacking the inventory bins in a regular flow and workplace housekeeping to adopting just-in-time (JIT) manufacturing, lean manufacturing improves production efficiency as well as cuts costs.

US-based startup ThroughPut develops ELI, a supply chain automation solution for the automotive, logistics, and manufacturing industries. The artificial intelligence-based engine integrates company-wide operations to identify and manage production constraints. Additionally, ELI supports roadmap planning, process optimization, and root-cause analysis, thereby enabling manufacturers to streamline production. ThroughPut’s solution also allows automobile manufacturers to balance demand and capacity management as well as reduce downtime, scrap, and rework.

DevisionX develops an Automated Quality Inspection System

Quality control is an integral part of the automotive industry and lean principles strengthen it. For example, integrating lean principles like total productive maintenance (TPM) in production minimizes breakdowns, manufacturing defects, and accidents. Also, quality control ensures customer safety and reduces liability risks, thereby avoiding expensive recalls and car accidents. Further, high-quality products increase customer loyalty and ultimately improve repeat business as well as new customers from referrals.

DevisionX is an Egyptian startup offering an automated quality inspection solution. The startup uses machine vision and deep learning, along with connected industrial cameras or sensors, to detect various defects in raw materials and production parts. The machine vision system identifies, measures, gauges, and inspects the quality of the automobile assembly parts in the testing samples. On the other hand, deep learning algorithms extract real-time information from the test samples. This way, DevisionX significantly improves the otherwise time-intensive quality inspection and reduces the risks of manual errors.

ishttaa TechCraft reduces Downtime with Automation and the IIoT

Lean principles in automotive production allow vehicle manufacturers to reduce expenses due to overproduction, transportation, and inventory spends. This is possible as a result of advancements in the Industrial Internet of Things (IIoT) and data analytics. That is why startups offer IIoT and data analytics solutions that capture operational data from production floors and generate valuable insights into production workflows. This way, vehicle manufacturers are able to identify operational disparities and gain better visibility into their production processes.

ishttaa TechCraft is an Indian startup that provides industrial automation and IIoT solutions for automotive manufacturers. The startup’s integrated digital solutions for manufacturing enables original equipment manufacturers (OEMs) to track and trace production operations as well as the quality of the components. Plus, ishttaa TechCraft’s solution enables the overall equipment efficiency (OEE) of machinery in an automotive environment, thereby reducing downtime. Furthermore, it provides test-bench automation, manufacturing intelligence, and robot-based automation solutions for automotive manufacturers.

OnRamp Solutions offers Lean Enterprise Resource Planning (ERP)

ERP systems in a production environment rely on sales forecasts for material planning, whereas lean manufacturing uses pull-based production scheduling. However, startups integrate lean and ERP tools to bring the best of both worlds for automotive manufacturing companies. For instance, customized ERP solutions work along with lean principles on the production floor. Such systems improve efficiency at automobile production floors as well as reduce costs.

Canadian startup OnRamp Solutions develops ERP software for the automotive sector. The startup builds ERP systems around lean management methods to optimize inventory control to management and scheduling in one place. This allows automotive manufacturing companies to cut down implementation costs and boost profits. Additionally, OnRamp Solutions’ combines various databases into one, thereby eliminating data silos. The startup’s solutions also optimize production for process manufacturing and packaging industries.

ProcessMiner provides Autonomous Manufacturing Control

Machine maintenance has a critical role in reducing unwanted downtime on production floors. Unlike reactive or scheduled maintenance, predictive maintenance offers the resilience lean principles demands. When combined with autonomous control, it splits the load for maintenance and machine monitoring between operators and the maintenance system. Similarly, autonomous control systems in manufacturing allow OEMs to streamline their production at each operational level for uniform outcomes with maximum throughput and minimal resource wastage.

ProcessMiner is a US-based startup developing smart manufacturing and autonomous control for automotive manufacturing. The startup’s AI-enabled platform offers data acquisition and cleans historical data to predict improvement opportunities in production. The startup’s solution reduces raw material consumption and process variability. This, in effect, reduces overall production costs, increases efficiency, and provides a competitive edge.

Discover more Automotive Startups

Automotive startups such as the examples highlighted in this report focus on autonomous vehicles, connectivity, shared mobility as well as electrification. While all of these technologies play a major role in advancing the automotive industry, they only represent the tip of the iceberg. To explore more automotive technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Automotive Innovation Report to save your time and improve strategic decision-making.

![Explore the Future of AI in the Automotive Industry [2025 & Beyond]](https://www.startus-insights.com/wp-content/uploads/2024/10/Future-of-AI-in-Automotive-Industry-SharedImg-StartUs-Insights-noresize-420x236.webp)