Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the energy industry. This time, you get to discover 5 hand-picked waste heat recovery solutions.

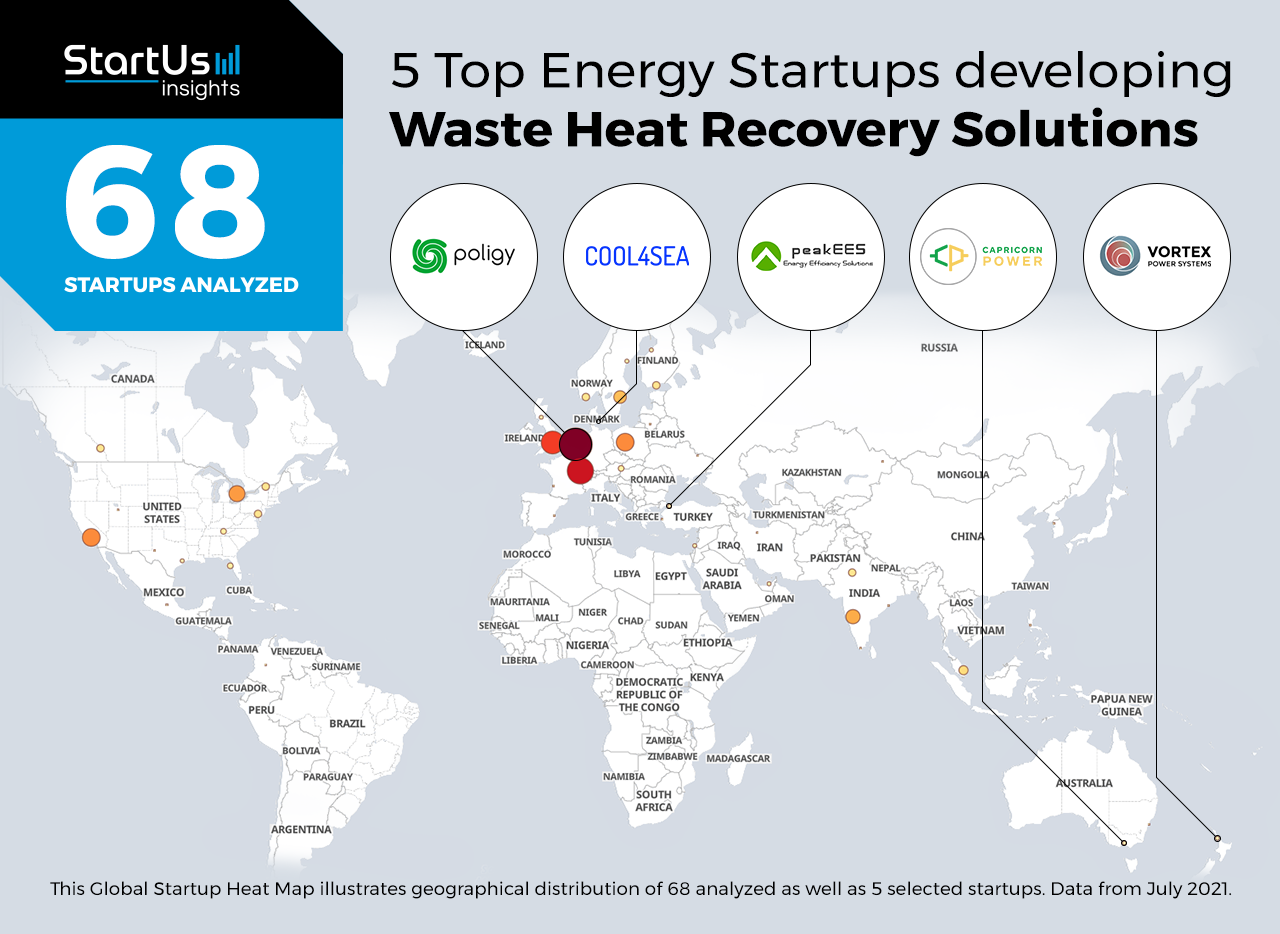

Global Startup Heat Map highlights 5 Top Waste Heat Recovery Solutions out of 68

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 68 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 energy startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 63 waste heat recovery solutions, get in touch.

Capricorn Power provides Heat Recovery Engines

Biomass pyrolysis is a carbon capture process that produces biochar as a byproduct. Biochar’s carbon-rich nature and stability in the soil make biomass pyrolysis an effective method of carbon sequestration. But a large fraction of the heat involved in the pyrolysis process gets wasted. So energy startups and scaleups are developing heat recovery systems that make use of this waste heat. These solutions help convert biochar facilities into sources of clean energy.

Capricorn Power is an Australian startup that develops heat-recovery engines that utilize waste heat to generate electricity. The startup’s Barton engine uses air as the working gas which absorbs waste heat from the pyrolysis unit. A piston rotor system with an electrical generator uses this hot expanding air to produce clean electricity. Further, the startup’s engine design allows it to work with any heat source over 400 ℃. This converts industrial furnaces, landfill incinerators, biomass pyrolysis units, and waste incinerators into zero-emission energy sources.

peakEES advances Thermo-Mechanical Systems

Thermo-mechanical equipment like steam boilers, industrial furnaces, and compressors are integral parts of an industrial facility. A large amount of the input energy to the equipment is lost as heat, thus reducing the efficiency of the entire industrial process. So startups are developing heat recovery systems that reuse this waste heat. This increases the overall efficiency of the equipment by repurposing waste heat for supplementary needs.

Turkish startup peakEES develops waste heat recovery solutions for thermo-mechanical equipment, including economizers and recuperators that recycle waste heat. The startup identifies the waste heat points by evaluating the efficiency of the equipment. Then, specially designed heat exchangers recover this heat from these points and supply it to the inlet fluids. This avoids the need for burning extra fuel for initial heating, in turn, reducing fuel consumption and operating costs.

COOL4SEA utilizes Absorption Cooling

A combustion engine is the source of energy for almost all fuel-driven vehicles, from cars to ships and aircraft. In these mobile units, the waste heat from engines is an untapped source that reduces fuel consumption. This is why energy startups are developing techniques to utilize the waste heat from engines for powering onboard devices. These solutions are particularly useful for aircraft and ships for which mid-journey refueling is not economically viable.

COOL4SEA is a Danish startup that develops a heat recovery system that uses the waste heat of ships to cool the crew quarters and service areas. The startup uses the principle of absorption cooling where the refrigerant, aqueous Lithium Bromide (LiBr, is boiled under low pressure using the ship’s waste heat. Due to the non-toxic and less reactive nature of the LiBr refrigerant, the design of the system is simple, reliable, and requires only minimal maintenance. Further, to ensure optimal efficiency, the solution also offers a remote monitoring system to keep track of the process parameters.

Poligy provides Low-grade Waste Heat Recovery

In energy generation and consumption, more than half of primary energy production is lost in the form of waste heat. The current energy harvesting systems have poor efficiency in working with small temperature differentials. This leads to the underutilization of low-grade heat, under 100-230 ℃. In response, energy startups are developing sustainable solutions that turn low-grade waste heat into electricity. These solutions improve the efficiency of power generation and reduce operating costs.

Poligy is a German cleantech startup that transforms low-grade waste heat into electricity. The startup uses its patented bipolymer system that converts the bending of bipolymer material into a rotary motion which, in turn, generates electricity. The technology allows for the efficient recovery of waste heat within the range of 50 to 150℃. Poligy’s bipolymer setup also requires lower manufacturing costs, is compatible with other materials, consumes less wear, and is more sensitive to temperature fluctuations, and offers good corrosion resistance. This makes the system durable to produce ecologically sustainable electricity.

Vortex recovers Energy from Power Plants

The thermal processes in a power plant are inefficient since most of the energy from the fuel escapes as heat. This leads to the use of more fuel, resulting in more carbon emissions. To avoid this loss of heat, startups are developing technologies that allow the recovery of waste heat from power plants. These heat recovery solutions utilize low-grade energy which is otherwise wasted.

Vortex is a New Zealand-based startup that develops heat recovery solutions for power plants. The startup creates a controllable vortex with water vapor by inducing a temperature gradient using the energy from waste heat. The solution further uses a wind turbine at the base of the vortex to convert the wind from the vortex into power. This extra electrical energy from waste heat enables power plants to meet the demand from the grid using less fuel and also reduce their carbon emissions. Additionally, this solution eliminates the need for a cooling tower, thus, reducing the capital expenditure of the plant.

Discover more Energy Startups

Energy startups such as the examples highlighted in this report focus on combined heat & power (CHP), commercial heating, and power to hydrogen. While all of these technologies play a major role in advancing the energy industry, they only represent the tip of the iceberg. To explore more energy technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Energy Innovation Report to save your time and improve strategic decision-making.