Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into industry 4.0. This time, you get to discover 5 hand-picked startups enabling predictive quality.

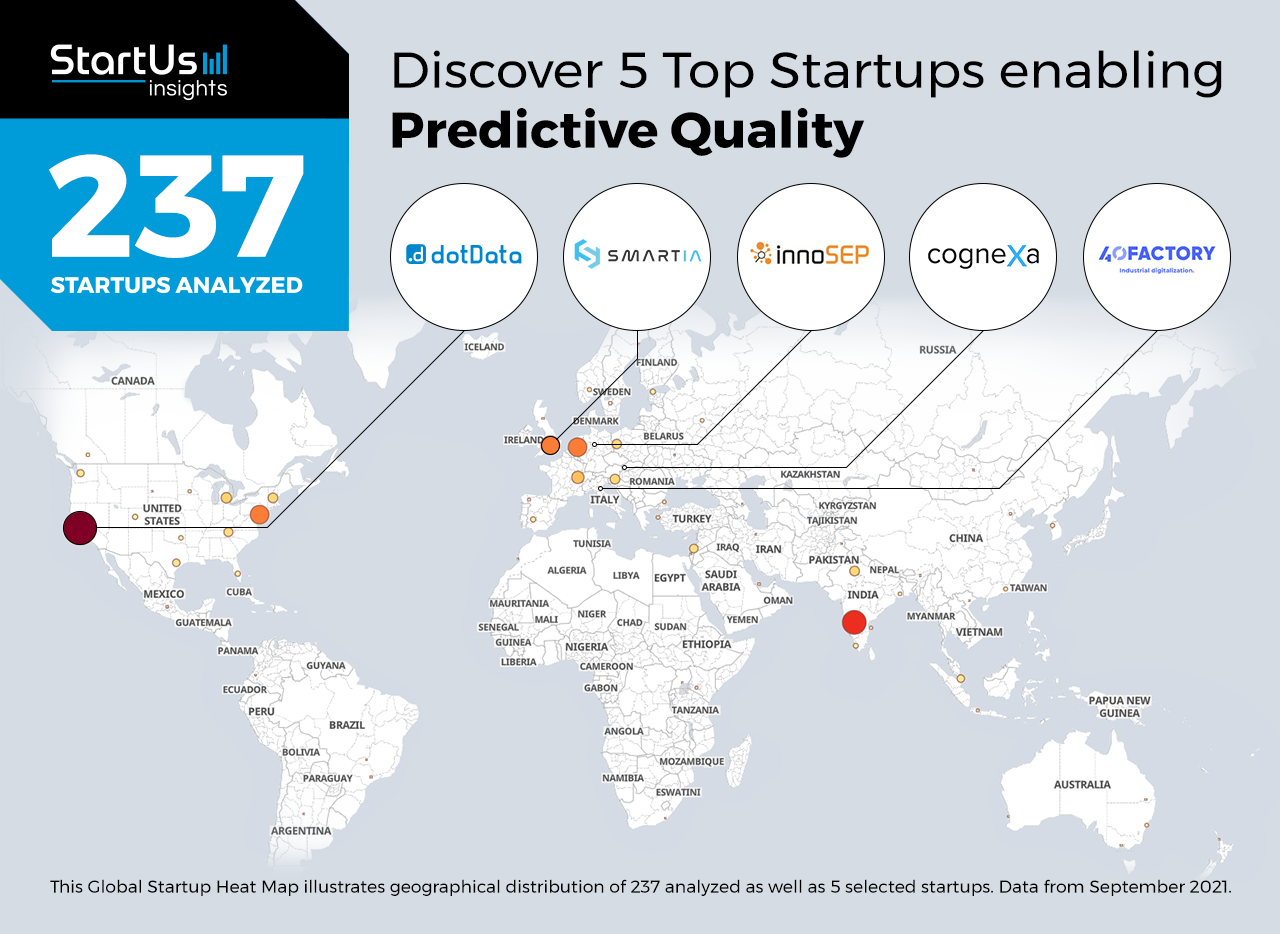

Out of 237, the Global Startup Heat Map highlights 5 Top Startups enabling Predictive Quality

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 237 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 232 predictive quality startups, get in touch.

Smartia enables Process Failure Prediction

A defective product holds only scrap value, especially in the case of composite products that are commonly single-piece objects. Moreover, the highly stressed nature of the environment these products operate increases the potency of even small cracks. This is why startups and scaleups are developing solutions that predict failures before they occur and improve quality control at the time of production. These solutions utilize artificial intelligence (AI) to create predictive models of the product.

Smartia is a UK-based startup that develops AI-based solutions to automate quality control applications. The startup’s MAIO collects data from machines and other relevant sources to develop a machine learning (ML) classifier. Using this, Smartia’s neural networks predict failures before the point of no return. The startup also develops a computer vision solution that detects faults and automates the inspection process. With these solutions, the startup assists manufacturing companies to forecast quality issues before they happen, in turn, reducing energy consumption and materials wastage.

Cognexa monitors Quality Compliance

The successful implementation of a quality management system removes unwanted line stoppages and material wastage. But the current methods in quality assurance capture defects only at end of production lines. On the other hand, industry 4.0 techniques like AI and big data assist startups and scaleups in providing solutions that ensure quality compliance continuously.

Cognexa is a Slovakian startup that provides quality control solutions. The startup develops an AI-based computer vision technology that detects surface defects and anomalies early in the production line and prevents the scrapping of assembled products. The startup also creates digital twins and predictive quality models that forecast control, minimize rejection levels, and fine-tune production processes. Further, Cognexa’s solution includes an analytics platform that recognizes patterns and provides insights on data from sensors and other sources. These insights ensure that the production line works at maximum efficiency with minimal wastage of resources.

40 Factory provides Product Quality Forecasts

The digitization of manufacturing processes leads to the generation of a multitude of data. However, not all data is controlled by the shopfloor workers, making it difficult to determine their impact before errors are made. The absence of a platform to coordinate this data renders its collection to be of no value. This is why startups and scaleups are offering data-driven solutions that create predictive models for production optimization.

Italian startup 40factory develops a machine learning tool for managing the relationship between manufacturing variables. The startup’s algorithm automatically maps the correlation between the input variable and the process output to create a predictive model. This allows companies to predict one or more key performance indicators, like production fallout, starting from the input data. 40factory further offers a tool to evaluate the effects due to variations in process parameters and external conditions on the product’s performance and quality.

dotData facilitates Warranty Planning

Every product has a particular warranty period it needs to serve the customer. End-of-line inspections and testing are the last points where manufacturers can identify defects that may shorten the life of a product. But for a fully assembled product, these defects are difficult to detect with visual inspections and limited test runs. This is why industry 4.0 startups are developing warranty planning solutions to predict issues that may occur in a product’s lifetime.

dotData is a US-based startup developing AI-powered data analytics solutions to enable smart manufacturing. The startup’s platform combines operation and sensor data in shipped products to create failure prediction models that identify high-risk products in advance. This reduces maintenance costs and improves customer satisfaction. In addition, Dotdata provides ML models that use shop-floor data to perform predictive maintenance, identify quality issues, and optimize the supply chain.

innoSEP offers Design-Level Quality Control

Designers factor in safety features to improve the performance quality of their products. But due to hidden factors, both in the manufacturing line and at the customer’s end, these features do not always prevent failures. This is why startups are offering solutions that ensure more effective implementation of built-in quality. Such solutions utilize predictive models to identify all factors that affect product performance.

German startup innoSEP provides an AI-based platform that uses product data to optimize product designs. The startup’s platform collects data from development information, knowledge-based systems, and field process data and then creates a predictive model to identify possible defects along the product’s lifecycle. This allows engineers to develop products with improved quality in addition to reducing testing, simulation time, and time-to-market (TTM).

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on quality management, inspection automation as well as smart manufacturing. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore more industrial technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.