This article details 10 new robotic assembly line solutions. These innovations enhance precision, efficiency, and flexibility while enabling the automation of complex tasks traditionally reliant on human intervention. However, despite their potential, these technologies face challenges, including integration complexities, high implementation costs, and the need for robust cybersecurity measures. As industries navigate these hurdles, smarter and more efficient production lines continue to evolve robotic manufacturing solutions. We last updated this report 5 days ago. Tell us if you find something’s not quite right!

Continue reading to gain up-to-date and data-driven insights on:

- Profiles of 10 Emerging Robotic Assembly Line Companies

- How to Scout Top Robotic Assembly Line Solutions Easily

Key Takeaways

Drawing insights from the Big Data & AI-powered StartUs Insights Discovery Platform that provides data on over 4.7+ million emerging companies globally, we explore the evolving landscape of the manufacturing industry. This sector is marked by key trends and a substantial workforce, shaping its future. Here are some key insights at a glance:

- Latest Production Line Robotics Trends: Some of the latest production line robotics include collaborative robots (cobots), autonomous mobile robots (AMRs), mobile manipulators, digital twins, robots as a service, and humanoid robots.

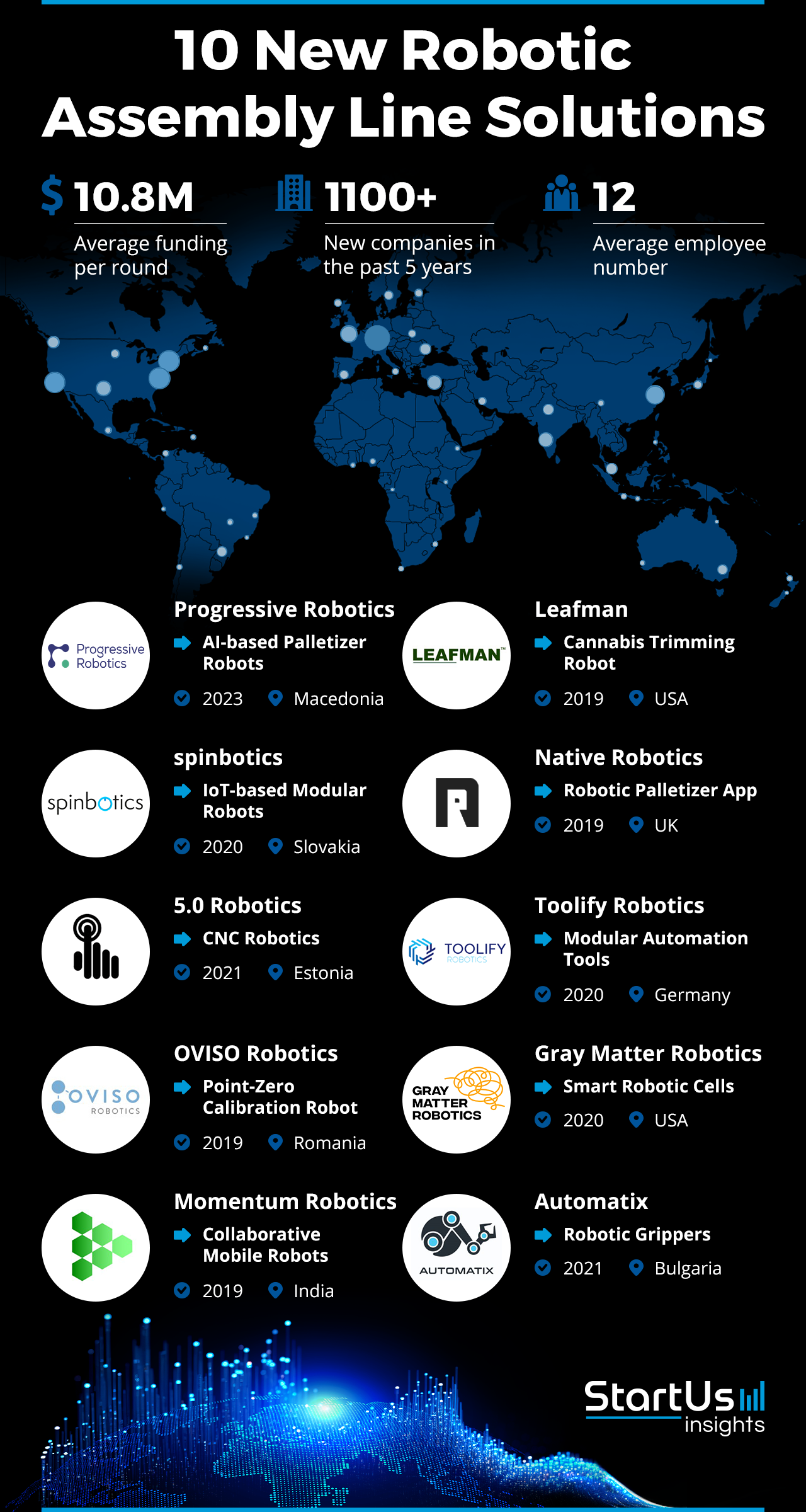

- Production Line Robotics Market Stats: The sector comprises 11.5K+ organizations worldwide. Out of these, 1.1+ new robotic assembly line solutions were founded in the last five years, witnessing 2020 as the average founding year. On average, each of these companies employs about 12 people. Moreover, the average funding received by these 1.1K+ production line robot companies per round in the same span is USD 10.8 million.

- 10 New Robotic Assembly Line Solutions to Watch:

- Progressive Robotics – AI-based Palletizer Robots

- spinbotics – Internet of Things (IoT)-based Modular Robots

- 5.0 Robotics – Computer Numerical Control (CNC) Robotics

- OVISO Robotics – Point-Zero Calibration Robot

- Momentum Robotics – Collaborative Mobile Robots

- Leafman – Cannabis Trimming Robot

- Native Robotics – Robotic Palletizer

- Toolify Robotics – Modular Automation Tools

- Gray Matter Robotics – Smart Robotic Cells

- Automatix – Robotic Grippers

Discover 10 out of 1.1K+ Emerging Robotic Assembly Line Solutions

In this section, we spotlight 10 new robotic assembly line solutions that enhance manufacturing solutions. These companies address industry challenges and adapt to market shifts. By leveraging technologies such as AI, advanced robotics, and sophisticated sensor systems, these robotic assembly line solutions enable precision engineering and increased productivity.

Note on Signal Strength

One of the unique metrics we feature for each company is Signal Strength, a proprietary data point generated by our Discovery Platform. It gauges the extent to which a company’s influence has permeated the global ecosystem of startups, scaleups, and emerging companies. This proprietary metric serves as a valuable guidepost for understanding a company’s standing in the broader market landscape.

1. Progressive Robotics

- Founding Year: 2023

- Employee Range: 2-10

- Location: Macedonia

- Signal Strength: Strong

- What they do: Progressive Robotics offers Progressive Brain, an AI-powered controller. It enables robots to see, think, and react through a touch interface as well as automates tasks like palletizing, packing, unpacking, and sorting. Progressive Brain’s AI-driven software develops picking strategies for diverse objects and optimizes packing configurations. The controller’s real-time motion planning and scene understanding algorithms provide object handling and placement. The company’s solution allows the food, pharma, and manufacturing industries to automate various assembly line tasks.

2. spinbotics

- Founding Year: 2020

- Employee Range: 11-50

- Location: Slovakia

- Signal Strength: Very Strong

- What they do: Spinbotics develops Spinbot Modular Kit, a configurable robot solution to automate monotonous tasks. This kit includes base connectors, drive units, angle connectors, straight connectors, and end tool connectors, each with interfaces and internal media feeds for data and energy. Its digital integration also provides a testing and deployment process to adapt to task changes. Additionally, its IoT connectivity supports local or remote predictive maintenance while the zero code development allows for easy task configuring, plugging, and automation. This assists in robotizing monotonous tasks in production and non-production processes across industries like manufacturing, automotive, electronics, and pharmaceuticals.

3. 5.0 Robotics

- Founding Year: 2021

- Employee Range: 2-10

- Location: Estonia

- Signal Strength: Very Strong

- What they do: 5.0 Robotics manufactures production robots, The Executive Series. The Executive Series CNC machines feature a steel frame, closed-loop servo motors, large ball screws, and dual ceramic bearings spindles to provide performance and accuracy. The CNC machines support materials such as plastics, wood, aluminum, or steel and feature upgradability options like laser engraving and 3D probing. They also use finite element analysis (FEA) and a spindle system with automatic air drive pick and place (ATC) automatic tool change. These machines reduce costs and increase productivity in the manufacturing industry.

4. OVISO Robotics

- Founding Year: 2019

- Employee Range: 11-50

- Location: Romania

- Signal Strength: Strong

- What they do: OVISO Robotics builds OVI, a point-zero calibration system that enables robots to determine exact positions and precisely adjust waypoints automatically. Its Magic Connector provides error-free operation with integrated utilities like pneumatic supply and power. The fast tool change system allows tool replacements and automatic parameter adjustments. Moreover, OVI eliminates the need for third-party integrator services by managing installation data and specific inputs and outputs (IOs) for each station. Further, it includes built-in sensors that enhance operational safety to prevent accidental damage. OVI moves manually too using a forklift or an automated guided vehicle for repositioning across different production lines.

5. Momentum Robotics

- Founding Year: 2019

- Employee Range: 2-10

- Location: India

- Signal Strength: Medium

- What they do: Momentum Robotics offers collaborative mobile robots for the automotive manufacturing industry. Its products, Cyborg 250, Cyborg 500, and Cyborg 1000, have a payload capacity of 250 kg, 500 kg, and 100 kg to transport goods and materials. These robots enhance production efficiency by handling raw materials and simplifying inventory management in assembly lines. The company’s robotic fleet platform further enhances operational efficiency and streamlines workflows by augmenting existing resources. These features eliminate bottlenecks, reduce manual labor, and minimize errors.

6. Leafman

- Founding Year: 2019

- Employee Range: 2-10

- Location: USA

- Signal Strength: Medium Strong

- What they do: Leafman provides a cannabis trimming machine, Leafman Alien Trimmer, and a transport system robot, Sanicon. Leafman Alien Trimmer leverages AI microprocessors to autonomously manage trimming speeds, up to 1000 lbs/hr. This eliminates the need for manual adjustments and maintenance. Sanicon automates bud conveyance with a no-contact belt system to provide cleanliness and efficiency. Both systems suit indoor cannabis farms and clean room operations to meet sanitization standards. The company’s robots reduce labor costs and enhance production rates with features like fault detection, auto-speed control, and maintenance-free operation.

7. Native Robotics

- Founding Year: 2019

- Employee Range: 11-50

- Location: UK

- Signal Strength: Very Strong

- What they do: Native Robotics builds a robotic palletizer configurator, OmniPack, and a robot visualizer, OmniFit. OmniPack features the next unit of computing (NUC) for easy integration and control. Its advanced motion planning algorithm enhances robot speed and smoothens motion to improve performance. OmniFit offers hyper-realistic AR models and interactive simulations to visualize robotic cells. These products handle errors and resolve issues while the algorithms calculate optimal trajectories for robot movement and optimize floor efficiency.

8. Toolify Robotics

- Founding Year: 2020

- Employee Range: 2-10

- Location: Germany

- Signal Strength: Very Strong

- What they do: Toolify Robotics offers XITO, a digital engineering tool and process companion. It encompasses XITO Designer, XITO Marketplace, and XITO Builder. XITO Designer is a planning and construction tool that visualizes robotics applications to create and simulate ideas in 3D. XITO Marketplace is a sourcing portal for robotics components that streamlines procurement by improving access to essential parts. XITO Builder offers a low-code development environment to set up and commission robotics applications. These solutions assist in machine loading, material handling, palletizing, dispensing, material removal, assembly, transportation with mobile robots, and quality control.

9. Gray Matter Robotics

- Founding Year: 2020

- Employee Range: 11-50

- Location: USA

- Signal Strength: Very Strong

- What they do: Gray Matter Robotics builds AI-powered robotic solutions for high-mix manufacturers. The company utilizes proprietary AI technology and smart robotic cells that adapt to varying parts and configurations to eliminate the need for manual programming. They automate tasks like sanding and surface finishing and minimize scrap, rework, and repair needs. Additionally, they feature single-arm, dual-arm, and mobile setups to provide flexibility in operational needs. These solutions cater to industries like aerospace, defense, marine, shipbuilding, specialty vehicles, general manufacturing, and consumer products.

10. Automatix

- Founding Year: 2021

- Employee Range: 2-10

- Location: Bulgaria

- Signal Strength: Medium

- What they do: Automatix develops RoboTend, a module that optimizes production processes. It features replaceable raster plates to accommodate various part sizes and shapes. The module’s compact design includes a built-in compartment for robot controllers and external programmable logic controllers (PLCs) as well as handles workpieces up to 160 mm high with shelf loads up to 100 kg. Its mobility repositions with forklifts to suit small to medium production runs. As a result, RoboTend enhances production efficiency with high-speed operations and part placement to ensure optimal machine loading. This assists industries like metalworking, plastic manufacturing, and automotive.

Quick Tip to Find New Robotic Assembly Line Solutions

Utilizing a SaaS platform like the Discovery Platform for identifying new robotic assembly line companies provides significant benefits compared to traditional scouting methods:

- Increased Efficiency: The Discovery Platform offers advanced tools that streamline the scouting process. It replaces your hours of conventional desk research, saving time and resources in identifying robotic assembly line innovations.

- Access to Real-time Insights: Gain a competitive edge with up-to-date information on the latest trends in robotic assembly lines. The platform keeps you informed with near real-time updates on emerging robotic assembly line companies and news, enabling you to make swift and informed decisions.

- Precise Scouting: Customize your search to focus on specific niches within the robotic assembly line sector, such as AI-based palletizer robots, IoT-based modular robots, or point-zero calibration robots. The platform’s diverse filtering options allow you to target your scouting efforts precisely, ensuring that you find the most relevant and groundbreaking companies in the field.

Ready to Explore All New Robotic Assembly Line Solutions?

This overview highlights just a few robotic assembly line solutions from all 1.1K+ new companies currently covered by the Discovery Platform. To explore them all, book a personalized demo or download one of our free Industry Innovation Reports for a quick overview. We value collaboration with industry professionals to offer even better insights. Interested in contributing? Get in touch!