This article examines 10 new wind turbine maintenance companies and startups that deploy technologies ranging from unmanned inspection systems to drone-based inspection platforms for comprehensive blade and structure analysis. Other solutions include acoustic sensor-based monitoring that detects operational anomalies through sound pattern analysis or ultrasonic structure monitoring, which identifies internal defects with precision.

Each company contributes distinctively to advancing maintenance practices, underscoring the growing importance of technology in sustaining wind energy operations. This overview highlights the technological strides being made to ensure reliability and longevity in wind turbines through cutting-edge maintenance techniques.

Continue reading to gain up-to-date and data-driven insights on:

- Profiles of 10 Emerging Wind Turbine Maintenance Companies

- How to Scout New Wind Turbine Maintenance Startups Easily

Key Takeaways

Drawing insights from the Big Data & AI-powered StartUs Insights Discovery Platform that provides data on over 4.7+ million emerging companies globally, we explore the evolving landscape of the wind turbine maintenance industry. This sector is marked by key trends and a substantial workforce, shaping its future. This article was last updated 5 days ago. If you find any info is missing, let us know! Here are some key insights at a glance:

- Latest Wind Turbine Maintenance Trends: Some of the major trends impacting the wind turbine maintenance industry are Condition Monitoring Systems, Drones & Robotics, Predictive Maintenance, Digital Twin, and Thermal Imaging.

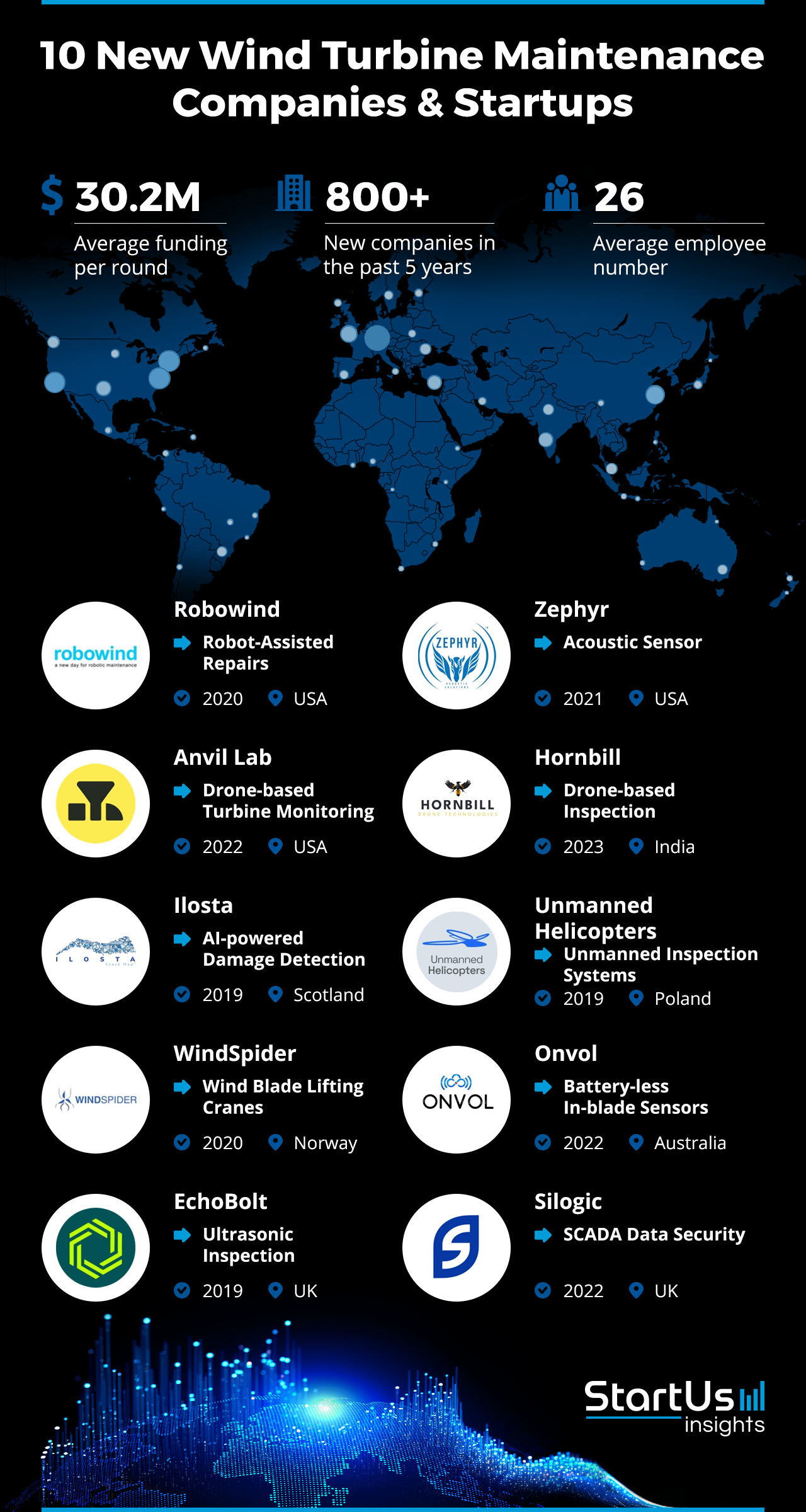

- Wind Turbine Maintenance Industry Stats: The sector is represented by 800+ new wind turbine maintenance companies that were founded in the last five years, witnessing 2020 as the average founding year. On average, each of these companies employs about 26 people. Moreover, the average funding received by the solar energy industry per round in the same span is USD 30.2 million.

- 10 New Wind Turbine Maintenance Startups:

- Robowind – Robot-Assisted Repairs

- Anvil Lab – Drone-based Turbine Monitoring

- Ilosta – AI-powered Damage Detection

- WindSpider – Wind Blade Lifting Cranes

- EchoBolt – Ultrasonic Inspection

- Zephyr – Acoustic Sensor

- Hornbill – Drone-based Inspection

- Unmanned Helicopters – Unmanned Inspection

- Onvol – Battery-less In-blade Sensors

- Silogic – SCADA Data Security

Meet 10 out of 800+ New Wind Turbine Maintenance Companies and Startups

In this section, we explore 10 new wind turbine maintenance solutions. These firms utilize robot-assisted repairs, drone-assisted turbine monitoring, and AI-based damage detection. They incorporate robotics, drones, and artificial intelligence to improve repair precision, monitoring reach, and damage analysis accuracy. Discover the sophisticated technologies and methods these companies employ to enhance the efficiency and effectiveness of wind turbine maintenance.

Note on Signal Strength

One of the unique metrics we feature for each company is Signal Strength, a proprietary data point generated by our Discovery Platform. It gauges the extent to which a company’s influence has permeated the global ecosystem of startups, scaleups, and emerging companies. This proprietary metric serves as a valuable guidepost for understanding a company’s standing in the broader market landscape.

1. Robowind

- Founding Year: 2020

- Employee Range: 11-50

- Location: USA

- Signal Strength: Very Strong

- What they do: Robowind develops robotic systems for wind turbine blade maintenance. The company’s robots perform blade inspections, clean using ablative lasers, and repair both Type 1 and Type 2 blade damage with UV-cured paints. The robots also install performance enhancements like vortex generators and noise reduction serrations. Ground operators control the robots, which eliminates the need for hazardous rope access or aerial lifts. Wind turbine operators benefit from enhanced safety, reduced maintenance time, and cost savings. The robots’ automated systems ensure efficient, reliable operations in various weather conditions. This technology optimizes turbine performance, ensuring long-term operational efficiency and profitability.

2. Anvil Lab

- Founding Year: 2022

- Employee Range: 2-10

- Location: USA

- Signal Strength: Medium Strong

- What they do: Anvil Labs provides drone-based inspection solutions for wind asset inspections and visualization. The company’s cloud-supported platform enables the capture and analysis of high-resolution 3D models and millimeter-precision data for wind turbines. Drones equipped with various sensors gather comprehensive data, including thermal and LiDAR data, to identify defects and monitor structural health. The solution supports automated reporting and data integration with other systems via API, enhancing operational efficiency. Wind turbine operators benefit from improved safety, reduced inspection times, and detailed analytics for maintenance planning. The solution’s ability to generate digital twins facilitates accurate, repeatable inspections, ensuring consistent monitoring and proactive maintenance.

3. Ilosta

- Founding Year: 2019

- Employee Range: 2-10

- Location: Scotland

- Signal Strength: Very Strong

- What they do: Ilosta offers an AI-based software solution that uses physics-based algorithms to predict defects, improving structural reliability and lifespan. The platform provides comprehensive 3D modeling that allows users to visualize and analyze asset data with high precision. Ilosta’s system detects leading-edge erosion, cracks, and other defects, offering accurate damage classification and evaluation. The technology benefits inspectors, surveyors, asset owners, and insurance providers by enhancing data analytics and operational efficiency. The cloud-based software ensures secure data storage and seamless collaboration with stakeholders. By integrating sensor fusion and 3D modeling, Ilosta optimizes maintenance processes and extends the life of engineering structures.

4. WindSpider

- Founding Year: 2020

- Employee Range: 2-10

- Location: Norway

- Signal Strength: Medium Strong

- What they do: WindSpider develops modular, self-erecting crane systems for wind turbine installation and maintenance. Their technology leverages the wind turbine tower itself to support the crane structure and offer scalability for lifts over 1500 tons without height restrictions. The WindSpider crane, dolly crane, and blade tool enable high operability in windy conditions, making them suitable for both onshore and offshore applications. This approach ensures integration with existing vessels and infrastructure, which reduces the need for specialized equipment. WindSpider’s solutions enable cost savings and improved safety by eliminating relative motion issues between the crane and turbine. The reduced installation and maintenance costs help operators improve uptime and enhance efficiency in operations. The modular design also allows for rapid mobilization and effective transport by road or sea, addressing the diverse needs of the wind energy sector.

5. EchoBolt

- Founding Year: 2019

- Employee Range: 2-10

- Location: UK

- Signal Strength: Medium Strong

- What they do: EchoBolt offers bolt inspection and maintenance solutions for wind turbines that utilize ultrasonic inspection technology. The solution assesses the integrity of bolted connections, eliminating the need for hydraulic retightening and significantly reducing maintenance costs. EchoBolt’s proprietary technique provides real-time monitoring and data analysis, enabling efficient asset management and health monitoring. The ultrasonic measurement training program supports customers with tailored training packages that ensure proper maintenance of bolted connections. EchoBolt’s solutions benefit wind farm operators by enhancing safety, reducing downtime, and improving operational efficiency.

6. Zephyr

- Founding Year: 2021

- Employee Range: 2-10

- Location: USA

- Signal Strength: Very Strong

- What they do: Zephyr provides aeroacoustic inspection and structural health monitoring solutions for wind turbines. The company’s technology uses compact arrays of microphones to measure sound pressure levels radiated by turbine rotors, allowing rapid, non-contact collection of high-resolution data while turbines remain operational. This data identifies damage types such as leading edge erosion, trailing edge cracking, and pitch controller errors by analyzing noise level variations in relation to rotor position. Zephyr’s methodology isolates and diagnoses root causes of damage, distinguishing issues like torsional oscillations and blade imbalance. The platform offers real-time monitoring and data analysis, enhancing asset management. This technology benefits wind farm operators by enabling precise damage detection, reducing downtime, and optimizing maintenance schedules.

7. Hornbill

- Founding Year: 2023

- Employee Range: 2-10

- Location: India

- Signal Strength: Medium

- What they do: Hornbill Drones offers drone-based technology for wind turbine inspection and maintenance. Drones equipped with high-end cameras and sensors provide comprehensive and reliable data for detailed analysis. The company’s software supports high-resolution imaging and thermal scanning to identify structural defects and optimize maintenance schedules. This technology benefits wind farm operators by enhancing safety, reducing downtime, and improving operational efficiency. The platform ensures rapid deployment and integration with existing systems that deliver superior performance in various environmental conditions.

8. Unmanned Helicopters

- Founding Year: 2019

- Employee Range: 11-50

- Location: Poland

- Signal Strength: Weak

- What they do: Unmanned Helicopters develops unmanned aerial vehicles (UAVs) for wind turbine maintenance and inspection. Its Beyond M series features gasoline-powered helicopters with a 55-liter fuel capacity, supporting a maximum payload of up to 50 kilograms and a flight time of 6 hours. The platform integrates a four-stroke engine and navigation systems that ensure precise and stable flight operations. The UAVs collect high-resolution data, enabling detailed analysis of turbine blades and structural components. The solution enables wind farm operators to improve inspection efficiency, reduce downtime, and minimize maintenance costs.

9. Onvol

- Founding Year: 2022

- Employee Range: 2-10

- Location: Australia

- Signal Strength: Very Strong

- What they do: Onvol utilizes kinetic energy harvesting technology to power IoT devices by converting wind turbine motion into electrical energy. The company’s product, VolPower, utilizes a weighted mass-driven electromagnetic generator paired with an energy optimization regulator. This system transforms the rotational motion of wind turbine blades into a regulated DC power source that supports in-blade condition monitoring systems. It operates reliably across temperatures ranging from -30°C to 80°C and withstands harsh conditions, being IP54 dust and water-resistant. The design simplifies installation, reduces maintenance costs, and eliminates the need for batteries, thereby reducing downtime and pollution. Stakeholders in wind farm operations benefit from this solution, enhancing operational efficiency and meeting ESG requirements.

10. Silogic

- Founding Year: 2022

- Employee Range: 2-10

- Location: UK

- Signal Strength: Medium Strong

- What they do: Silogic develops cybersecurity solutions to protect sensor data related to wind turbine maintenance. The company’s SCADA intelligence platform detects cyber-threats in real-time which ensures operational integrity. Tritium X4 audits SCADA data to train advanced algorithms. Deuterium X6 focuses on live cyber-threat detection, reporting suspicious activities immediately. Gluon X6 analyzes SCADA sensor data to predict and prevent costly operational failures. These solutions benefit wind farm operators by providing actionable insights through simple text reports.

Quickly Find New Wind Turbine Maintenance Companies and Startups

Utilizing a SaaS platform like the Discovery Platform for identifying new wind turbine maintenance companies and startups provides significant benefits compared to traditional scouting methods:

- Streamlined Efficiency: The Discovery Platform offers advanced tools that streamline the scouting process. It replaces hours of your conventional desk research, saving time and resources in identifying Wind Turbine Maintenance innovations.

- Access to Real-time Insights: Gain a competitive edge with up-to-date information on the latest trends in the Wind Turbine Maintenance industry. The platform keeps you informed with near real-time updates on emerging Wind Turbine Maintenance companies and news, enabling you to make swift and informed decisions.

- Tailored Exploration: Customize your search to focus on specific niches within the Wind Turbine Maintenance sector, such as ultrasonic sensing, drone-based inspection, or cybersecurity platforms. The platform’s diverse filtering options allow you to target your scouting efforts precisely, ensuring that you find the most relevant and groundbreaking companies in the field.

Explore All New Wind Turbine Maintenance Companies and Startups!

We’ve explored the dynamic landscape of the wind turbine maintenance industry, examining the latest trends and spotlighting exceptional companies driving innovation. To dive deeper, download our free Renewables Report or schedule a demo of the Discovery Platform for a customized exploration of these groundbreaking developments. Are you an insider in the startup or tech industry? We’d love for you to contribute to our content.