Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups in Industry 4.0. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising computer vision startups impacting industry 4.0.

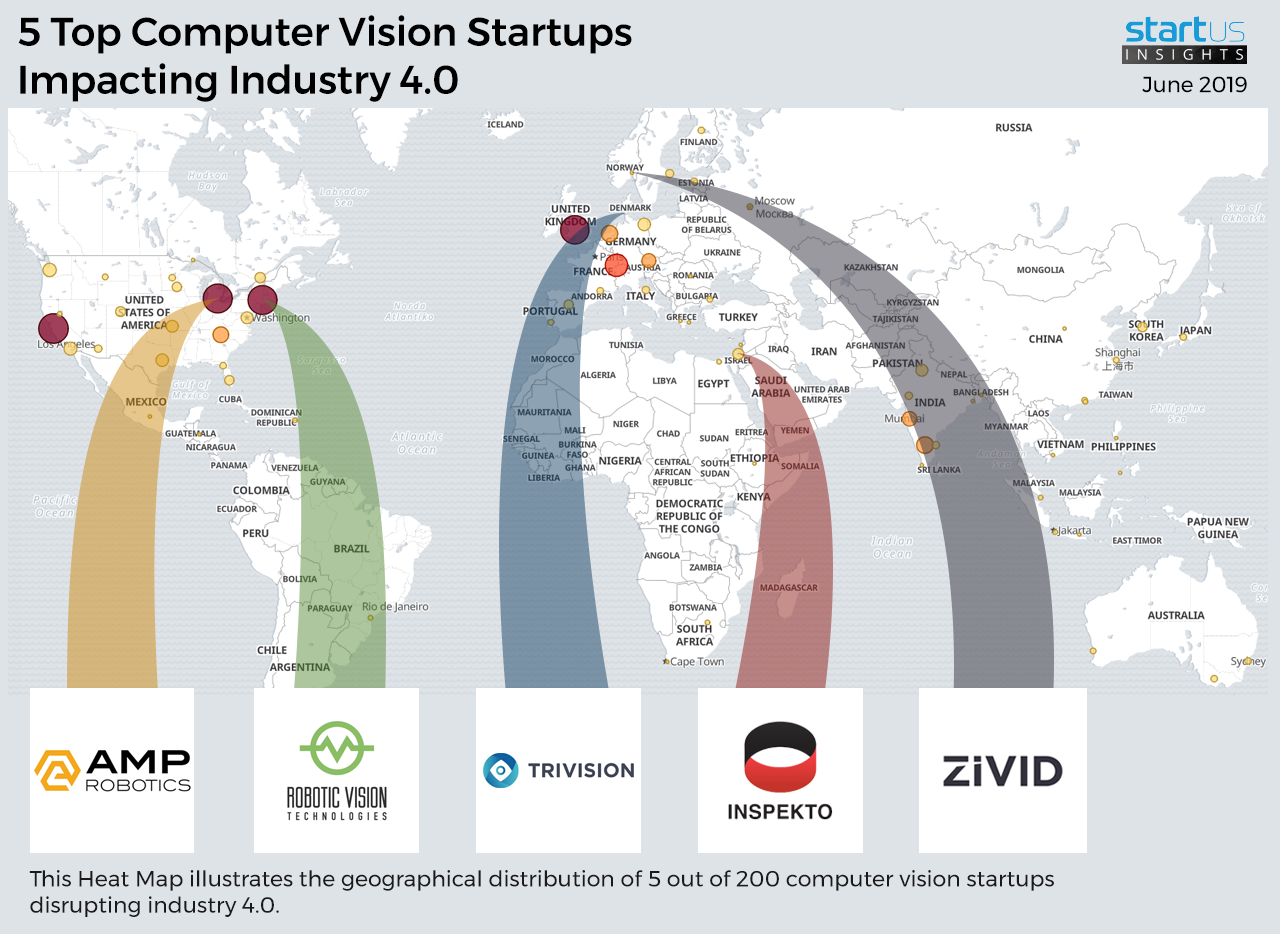

Heat Map: 5 Top Computer Vision Startups in Industry 4.0

For our 5 picks of computer vision startups, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 200 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Trivision – Package Inspection

This category includes machine vision solutions engineered to inspect a specific item type, label, or code, in an effort to eliminate costly recalls due to manufacturing errors in packaging and labeling. Such inspection systems can find errors in product packaging, labeling or coding, as well as detect problems such as seal or cap integrity issues. Danish startup Trivision offers an automated machine vision system for manufacturing optimization, which includes package surface inspection to avoid products with flaws in their appearance, and label inspection to avoid wrong information in products.

Zivid – Pick & Place

Pick and place machine vision solutions guide automated robots to pick and place a wide range of products for different applications. This solution consists of combining a 3D camera with software, which detects the position, orientation, and dimensions of objects. This enables the robot gripper to perform picking and placing quickly and accurately. Norwegian startup Zivid provides highly accurate real-time 3D color cameras, which brings a human-like vision to smart factories and warehouses of Industry 4.0. One of the application areas of such cameras is a machine vision system for pick-and-place robots. Using Zivid’s One camera in picking automation enables robot grippers to perform correct and safe extractions of objects on conveyor belts.

Robotic VISION Technologies – Positioning & Guidance

Many industrial manufacturing companies have installed automated robotic arms to help build products for vehicles and their parts, etc. A three-dimensional image allows these robots to perform more accurately and handle precise manufacturing calculations and movements when it comes to constructing parts or vehicles. This also ensures safe robotic movements when maneuvering around factory workers. The US-based startup Robotic VISION Technologies develops a 2D, 2.5D, and 3D guidance software, enabling image recognition, machine vision, machine learning, and robot guidance in industrial and non-industrial markets.

AMP Robotics – Objects Sorting

More and more factories are using robots to speed up their manufacturing process while making it cheaper, safer, and more efficient. These industrial robots can have cameras embedded in their arms or heads, and use a computer vision system (CVS) to analyze collected images in order to recognize objects. Based on the type of object they are confronted with, they analyze its characteristics and adjust their actions accordingly. In recycling plants, CVS is used to recognize various material types. The robotic machinery can place objects made of similar materials together. AMP Robotics from the US develops technology that automates the identification, sorting, and processing of material streams to extract maximum value for material recovery facilities. Their computer vision system can perceive unique material in piled, non-singulated waste and rapidly recognize consumer product branding and changes.

Inspekto – Process & Quality Control

Vision equipped machines are able to identify anomalies or defects in products or objects and flag them as not meeting certain quality assurance specifications. After a computer vision system recognizes a damaged product, factory workers can intervene and take action to remove or correct it. Automation of quality inspection and quality control processes help save time and costs, as well as improve the accuracy of results. Israeli startup Inspekto develops an integrator-less technology for visual quality inspection. This so-called Autonomous Machine Vision blends computer vision with Artificial Intelligence. Its visual system allows manufacturers to set-up, install and detect production defects in minutes. At the same time, it eliminates the costs of integration. Inspekto targets a wide range of vertical manufacturing sectors, including automotive and electronics.

What About The Other 195 Computer Vision Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 computer vision startups showcased above are promising examples out of 200 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.