Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the engineering sector. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 4 promising equipment condition monitoring startups.

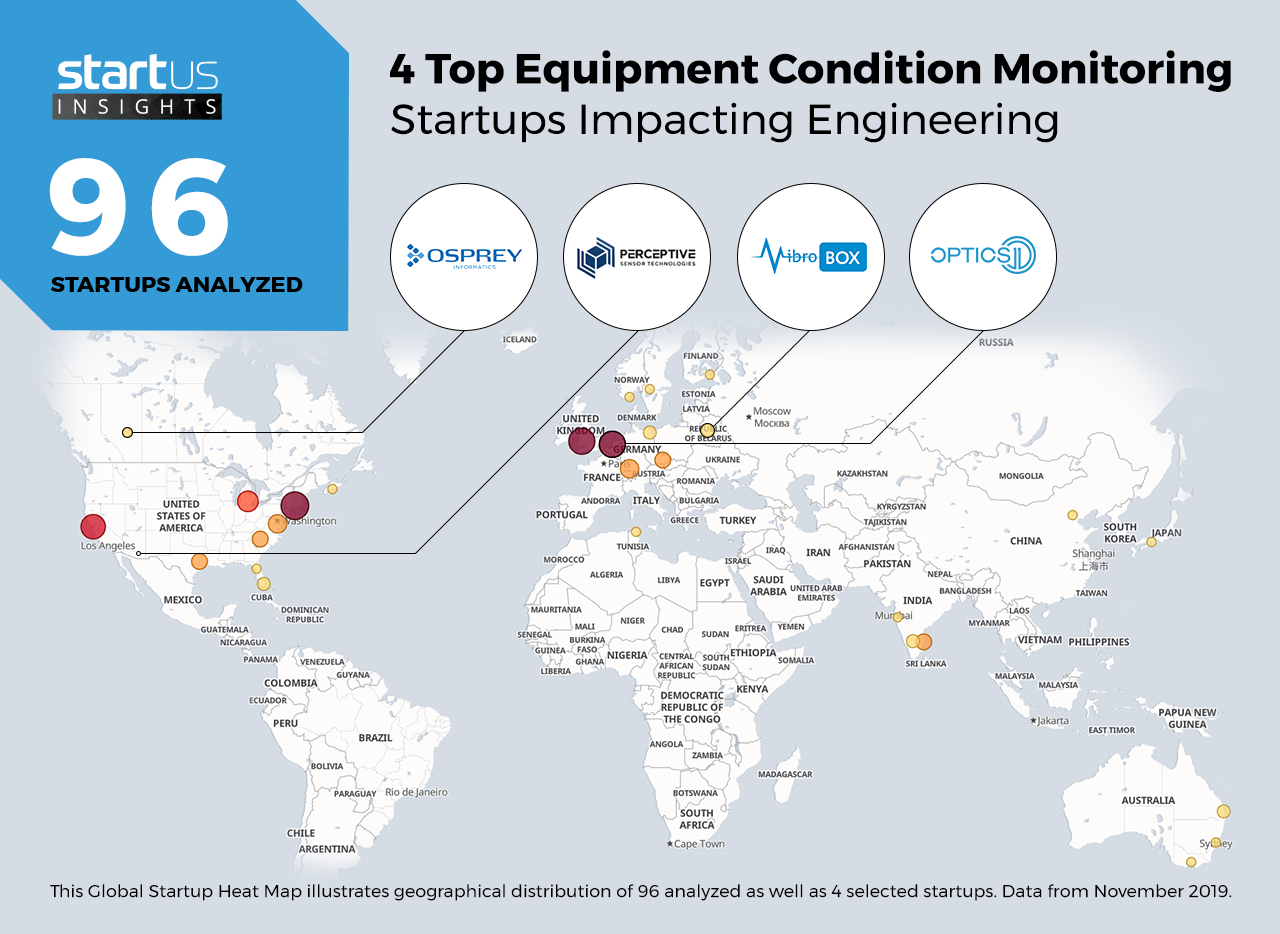

Heat Map: 4 Top Equipment Condition Monitoring Startups

For our 4 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 4 interesting examples out of 96 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

VibroBox – Vibration Analysis

Vibration analysis mitigates the risks of deterioration in industrial equipment or faults through surveillance testing by capturing and separating machine vibration signals, as well as identifying early signals and trends for machine degradation. Vibration monitoring usually amplifies the service life of bearings, streamlines overhaul processes and improves industrial safety at different stages of production. Belarusian startup VibroBox provides vibration diagnostics condition monitoring systems for rotary and reciprocating machinery. It applies machine learning and digital signal processing algorithms to provide automated diagnostics of equipment, build and analyze its digital twin and send report its potential health issues.

Optics 11 – Acoustic Emission Monitoring

Acoustic emissions monitoring operates at frequencies higher than in vibration analysis and enables the detection of damage at a very early stage with high precision. Generally, acoustic emissions technology pinpoints poor lubrication, potential breaks in slowly rotating equipment, and high vibration settings through transient stress recognition. Dutch startup Optics 11 develops OptimAE, a fiber optics acoustic emissions monitoring solution. Their solution uses interferometric sensors to detect strain in equipment in extreme temperatures, high current, and radiation. Besides, its multiplexing capacity enables sampling from 2 to 16 channels.

Perceptive Sensor Technologies – Ultrasound Monitoring

Ultrasound condition monitoring tackles the challenges of both equipment maintenance management and a shrinking industrial workforce based on quickly deployable systems that do not require high labor participation. They utilize heterodyning to capture and translate beyond-human-hearing short waves and localize their exact location in extremely noisy environments. The US-based startup Perceptive Sensor Technologies develops FluID, an ultrasound condition monitoring solution for tanks and liquid storage equipment. The sensors stay on the outer part of containers, but explicitly record velocity, impedance, and material density inside them based on a patented ultrasound “fingerprinting” algorithms.

Osprey Informatics – Infrared Thermography

Infrared condition monitoring has the ability to scan considerably large surface areas of machines quite fast. Thermal tests and benchmarking allow for observing hidden equipment temperature dynamics and patterns, identifying energy losses, and ensuring the safety of assets and people. Canadian startup Osprey Informatics provides a thermal condition monitoring and alerting system for industrial settings. Their cloud-based solution assists in weather-independent tracking of machinery and leaks conditions, configuring exception alerts and dispatching timely reports to the management and field operators.

What About The Other 92 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 4 startups showcased above are promising examples out of 96 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.