Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the pharmaceutical industry. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 5 promising additive manufacturing startups impacting the pharma industry.

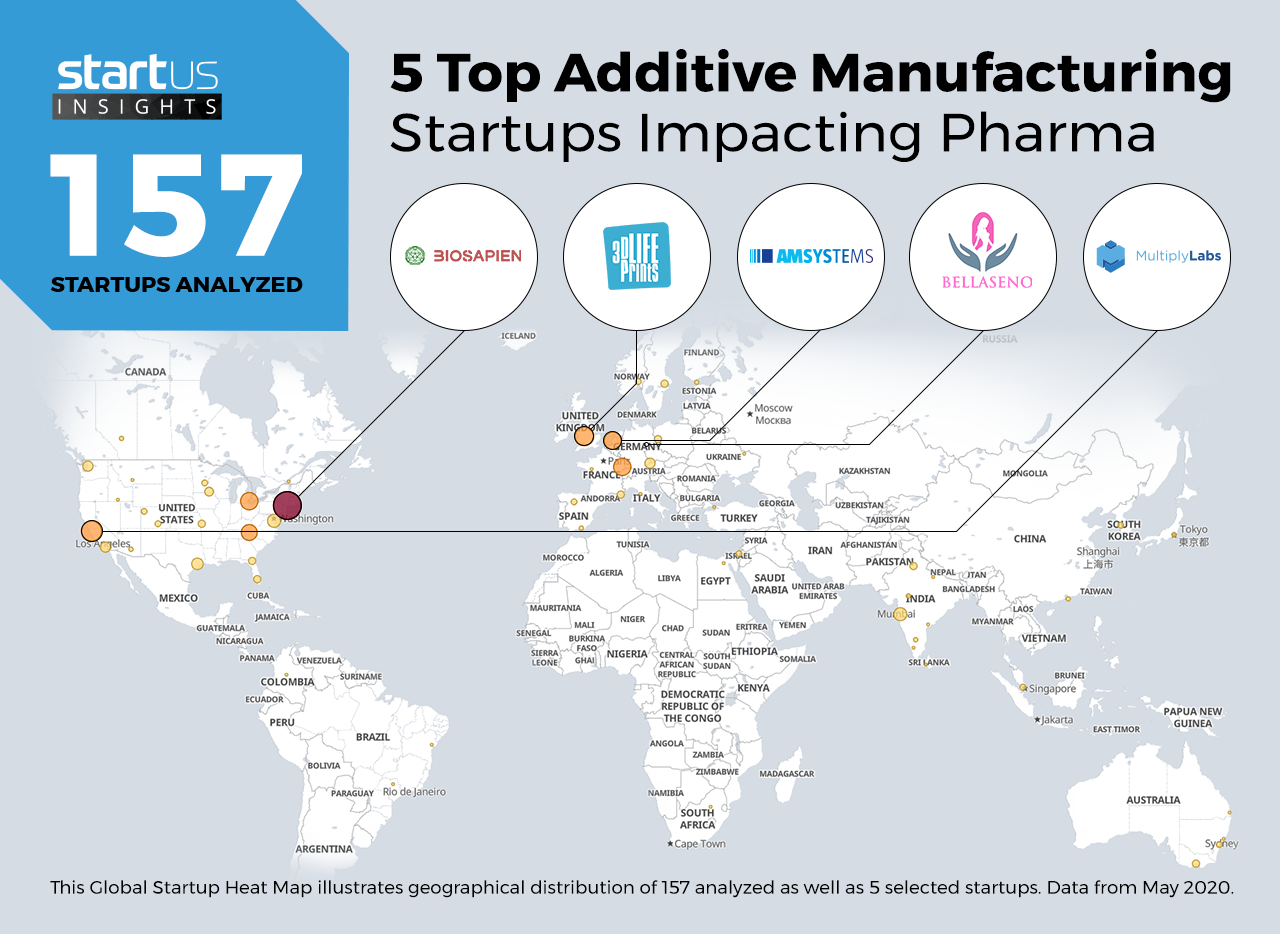

Heat Map: 5 Top Additive Manufacturing Startups Impacting The Pharma Industry

Using our StartUs Insights Platform, covering 1.116.000+ startups & emerging companies, we looked at pharma innovations. For this research, we identified 157 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and technology among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & emerging companies developing additive manufacturing solutions for the pharma sector. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 157 companies we analyzed for this specific topic.

Biosapien – Biodegradable Implant-Enabled Targeted Medication

Chemotherapy is administered in many ways including 3D printed biodegradable implantable devices that target delivery of medication straight at the tumor for specified periods. This reduces the number of times a patient visits a hospital and makes beds available for others in need. Since chemotherapy is targeted, the dosage of the medication is a fraction of what is used in conventional ways resulting in the reduction of harmful side effects.

The US-based startup BioSapien develops 3D printed biodegradable implants that deliver targeted cancer medication directly to the affected tissue. The longevity of controlled release ranges from 1 month to 5 years enabling increased duration of action. As a result, this decreases the harmful side-effects of chemotherapy including hair loss and nausea.

3D LifePrints – Imaging Phantoms

Medical imaging devices use imaging phantoms for calibration in order to determine the correct dosage for radiotherapy. Accurate dosage reduces the risk of radiating healthy tissue. Off the shelf, imaging phantoms are expensive and have long supply lead times. 3D printed phantoms are affordable and customizable to mimic any part of human anatomy.

British startup 3D LifePrints provides 3D printed thyroid phantoms using additive manufacturing. These phantoms, 3D printed with radiopaque materials, help mimic neck and throat tissue. As a result, medical professionals view tissues in 3D instead of CT/MRI scans that are traditionally 2D. To understand the exposure area of radiotherapy, the startup analyzes the radio-dosimetry data enabling medical professionals to achieve maximum precision in procedural planning for any specific prognosis.

Multiply Labs – Personalized Medicine

Chronic conditions often require multiple medication combinations. There is a high need for personalized medicine doses that combine all the medication a patient consumes in one pill. Since personalized medicine alleviates patients from having to remember to take the correct pill at the right time, patients focus on getting better without any additional stress.

The US-based startup Multiply Labs works in a smart robotic additive manufacturing facility providing personalized medicine in batches as small as 30 pills, effectively 1 month supply, for an individual patient. 3D printing capsules enables the startup to create pills that have multiple compartments allowing the release of specific medication at a predetermined time. Besides, with the help of differential thickness of the pill compartment, the startup is able to provide medicines that have a differential medicine delivery. As a result, each compartment breaks down at different speeds.

BellaSeno – Breast Scaffolds

Absorbable polymers combined with additive manufacturing help create breast scaffolds that are resorbed by the body. In comparison, these scaffolds perform better than traditional silicone breast implants. Usually, breast implants have a shelf life of 5 to 10 years and potentially result in complications like capsular contracture, rupture, and deflation. Moreover, scaffolds eliminate the risk of rejection and chronic infection resulting from foreign objects.

German additive manufacturing startup BellaSeno provides breast scaffolds that are 3D printed with biocompatible absorbable polymers. The patient’s body absorbs the breast scaffold fully and aids the breast tissue to regenerate simultaneously. As a result, this improves the quality of life for people recovering from a mastectomy.

AMsystems Center – Collaborative Facility For Additive Manufacturing

3D printing technology has multiple applications, especially in the pharma industry. These applications include prosthetics, drug delivery, braces, and implants. Pharma companies 3D print patient-specific pills and medication enabling reduced lead times. For this sector, startups and emerging companies work on innovative additive manufacturing solutions to overcome supply lead times in particular.

AMSystems Center, a Dutch-based joint innovation center, facilitates multi-material 3D printing technology in food, pharma, structural electronics. With the current focus on food, it also aims to move into pharma, focussing on 3D printing medicines and other pharma applications such as smart implants, bio-interfaces, and drug-eluting capability.

What About The Other 152 Startups?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 additive manufacturing startups showcased above are promising examples out of 157 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.