Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups in Industry 4.0. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising artificial intelligence (AI) solutions.

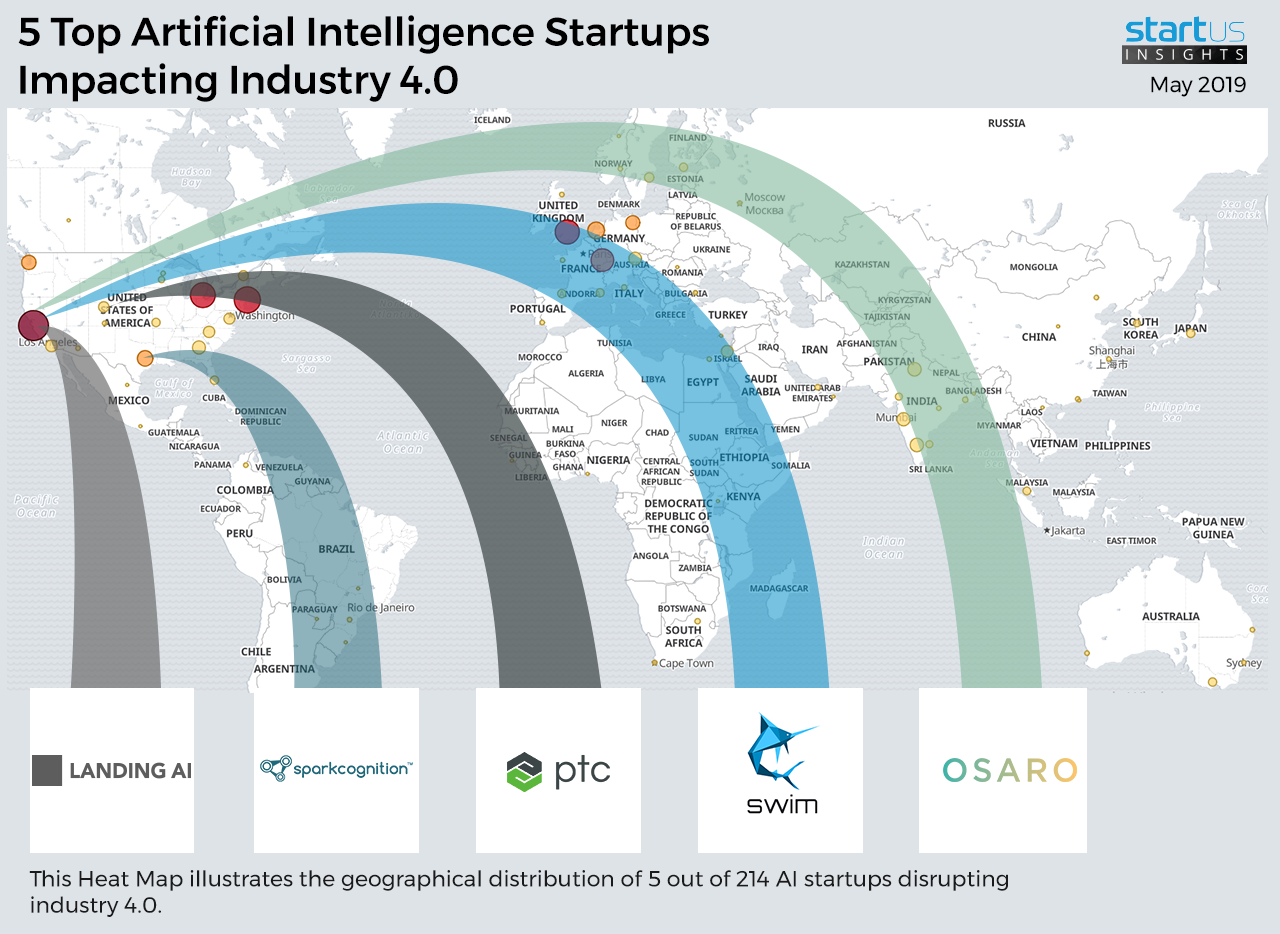

Heat Map: 5 Top Artificial Intelligence Startups

For our 5 picks of artificial intelligence startups, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 214 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Landing.ai – Automated Issue Identification

A system for automated identification of defects and problems on manufacturing lines is one example of AI in Industry 4.0. Once online, the computer not only “sees,” but also processes the information and learns from what it sees. If it spots a problem or defect, it sends an immediate alert — an AI process known as “automated issue identification”. The US-based company Landing.ai was formed by Andrew Ng, a famous machine learning engineer, who has developed machine-vision tools to find microscopic defects in products such as circuit boards at resolutions well beyond human vision. The main benefits of this tool are speed (30x faster than a human, identifying up to 400 objects/minute), scalability (take only 2-3 weeks to build and deploy), and the ability to build machine learning models with small datasets (15-20 labeled images per defect type).

SWIM.AI – Digital Twins

A digital twin is a virtual model of a physical system such as a manufacturing plant, or power plant, etc. This digital copy is a ‘twin’ of information embedded in the physical system. Such combinations of virtual and physical worlds allow the analyzing of data and monitoring of systems to detect problems before they occur. This prevents downtime, and even plans for the future by using simulations. The digital twin leverages the Internet of Things (IoT) and machine learning technology. SWIM.AI, a startup from the US, builds ML-powered digital twins of edge-device systems. These digital twins can interoperate in mesh architecture and support a wide range of autonomous, cooperative, and other edge-intelligence scenarios. They can also identify critical events, find hidden patterns, predict future behaviors, and autonomously trigger fast actions at an individual or multiple coordinated edge devices.

Frustum – Generative Design

Another use case of artificial intelligence in Industry 4.0 is a process called generative design. It starts when engineers input design goals into software, along with parameters for materials, manufacturing methods, and cost constraints. The software then explores all the possible permutations of a solution, and quickly “generates” design alternatives. Finally, it leverages machine learning to test and learn from each iteration what works and what doesn’t. US-based Frustum was acquired by PTC. Frustum develops Generate, which is a system that empowers engineers to create optimal designs faster through a balance of artificial intelligence and human insight. Leveraging its patented generative engine, Generate couples advanced topology optimization and simulation algorithms with real-time interaction, to quickly produce high-performing, ready to manufacture mechanical designs.

Sparkcognition – Prescriptive Maintenance

Prescriptive maintenance systems use AI to accurately anticipate when industrial machines will fail, as well as determine the most probable cause of failure, and define the best course of maintenance in a given situation. Natural language processing-powered algorithms can race through vast quantities of maintenance data — interpreting and organizing information from sensors and reports at the speed of light. The US company Sparkcognition develops AI-powered tools for predictive and prescriptive maintenance. These systems work with maintenance data where neural networks can analyze millions of potential associations, and identify precisely what caused a particular event and why.

Osaro – Robot Perception & Control

Combining the latest advances in AI and industrial robotics could bring significant advancements to Industry 4.0. The AI software for robot perception and control in combination with off-the-shelf cameras lets robots identify the objects in front of it and study how they behave when pushed or grasped. As with every AI system, it can learn from its experience in order to determine the best way of grasping particular objects. Osaro is a startup from the US which develops industrial grade AI perception and control software for robotic systems. Osaro’s platform has the ability to mimic behavior that requires learned sensor fusion, as well as high-level planning and object manipulation. It also has the ability to learn from one machine to another and improve beyond a human programmer’s insights.

What About The Other 209 Artificial Intelligence Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 AI startups showcased above are promising examples out of 214 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.

![AI and Business: A Strategic Guide for Industry Leaders & Corporates [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/02/AI-and-Business-SharedImg-StartUs-Insights-noresize-420x236.webp)