Our Innovation Analysts recently looked into emerging technologies and up-and-coming battery recycling & management businesses. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 5 promising battery recycling startups.

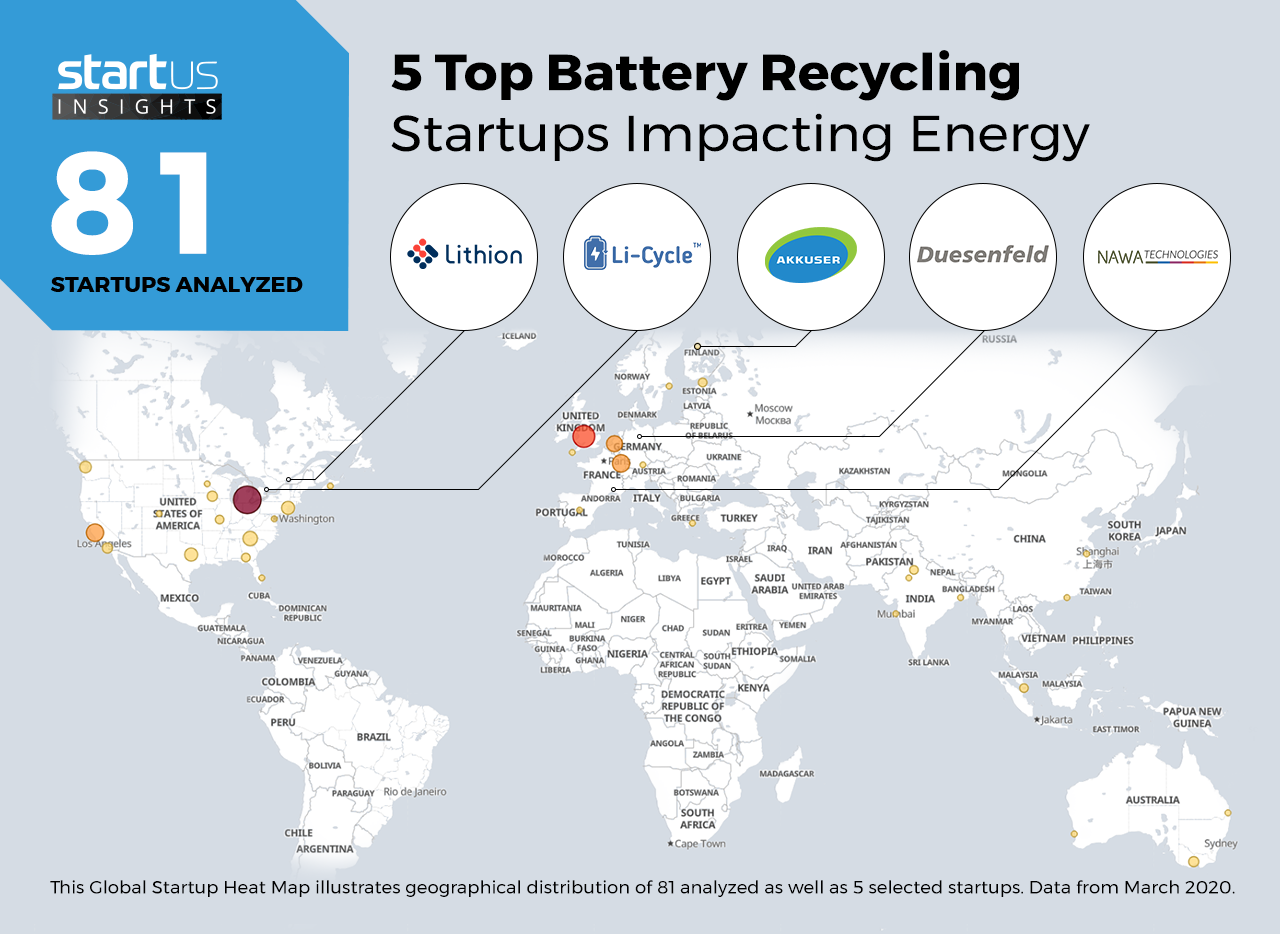

Heat Map: 5 Top Battery Recycling Companies

Through the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering over 3 790 000+ startups & scaleups globally, we identified 81 battery recycling startups. The Global Startup Heat Map below highlights the 5 startups you should watch as well as the geo-distribution of all 81 startups & scaleups we analyzed for this research. Based on the heat map, we see high startup activity in the US, followed by Western Europe.

Interested to explore all 80+ battery recycling companies?

Li-Cycle advances Hydro-Metallurgical Recycling

The rise in high-quality batteries is good as it weans humans away from fossil fuel-based energy. However, with new technologies come new problems, and the high levels of battery waste generated become detrimental to the value that electric batteries have. Hydro-metallurgical technology helps recycle important materials for batteries like lithium, manganese, cobalt, and nickel. This recycling process provides the best metal recovery and, therefore, facilitates reusing components of old batteries. This economically-viable technology provides affordable battery recycling solutions across industries.

Li-Cycle is a battery recycling company from Canada that uses a combination of mechanical size reduction and hydro-metallurgical resource recovery techniques designed for recycling lithium-ion batteries. The company provides the recycling technology for safely processing lithium-ion batteries that have minimal greenhouse gas emissions. As a result, it enables a sustainable end-of-life pathway for all lithium-ion batteries. The core benefit of their recycling technique is in the generation of a non-hazardous product that minimizes transportation liability and significantly lowers costs.

Lithion Recycling enables Direct Recycling Of Cathodes

Direct recycling allows for the easy extraction of valuable cathode materials and provides a cheaper alternative to battery manufacturers. This process potentially speeds up the global transition to clean energy and helps achieve carbon abatement targets. Direct cathode recycling technology also reduces reliance on the extraction of non-renewable resources. These recycled and regenerated cathodes, along with a few other materials, are appropriate for direct re-entry into the industry.

Canadian startup Lithion Recycling develops a battery recycling solution that recovers 95% of all components from lithium-ion batteries and regenerates materials with high purity. Their technology significantly reduces pressure for extracting raw materials and minimizes the ecological liability of battery-operated electric vehicles and other machines.

AkkuSer offers Curing Treatment Recycling

Proper waste management is essential for protecting the environment and reducing greenhouse gas emissions. The curing treatment method refers to the mixing of waste primary batteries with concrete ingredients. The technology uses very little energy, practically does not emit any carbon dioxide and eliminates toxic fluorine compounds. Curing treatments improve the quality of concrete by using waste batteries and reduces the pollution they otherwise produce due to the characteristics of concrete. Moreover, this method is easily scalable.

Finnish company AkkuSer uses curing treatment technology to deliver clean, safe, local, and sustainable lead recycling. Their recycling process enables safe treatment of reactive battery waste and a high recycling efficiency, with more than 50% of the materials contained in batteries being recovered. The batteries are then sorted into different fractions based on their metal and chemical content in order to enable maximum recovery of valuable battery metals.

NAWA Technologies provides a Biological Recycling Technology

Biochemical processes in battery recycling include bioleaching, bio-oxidation, biosorption, and bioaccumulation. In these reactions, organic material, oxygen, and bacteria interact in order to separate metal components. The main benefit of biological recycling technology is reduced pollution which is what makes this a clean technology. But it also faces challenges such as a long leaching time, a low leaching rate, and low overall efficiency. Startups are working to identify which materials are most effectively recycled with this technology.

NAWA Technologies, a French company, works on the Ultra Fast Carbon Battery using biological battery recycling to sort waste batteries based on their chemical composition. Their recycling process reduces the need for rare materials and sources carbon from biomass. After shredding and refining, their process results in a product called black mass, which contains electrolytes, zinc, manganese oxides, and other metals. Their recycling processes do not lead to volatile nano-objects and take into account the end-of-life constraints right from the design stage.

Duesenfeld develops an Electrolyte Recovery Method

The electrolyte recovery method resolves the problem of irreparable damage to a battery’s core. The technology applies low-freezing temperatures to erase the harmful effects of the electrolytes and adds water by electrolyte distillation for catalyzing. This method does not produce toxic fluorine compounds and allows for reduced energy consumption, especially after the combustion and washing stages.

German Duesenfeld builds an electrolyte recovery method that combines mechanical and thermodynamic processes in order to save the energy required for recycling and also to recover more raw materials. They employ energy-efficient processes and are capable of recovering a substantial amount of material. This ensures they have a low carbon footprint after completing recycling operations.

Discover All Emerging Energy Startups

The battery recycling solutions showcased in this report are only a small sample of all startups we identified through our data-driven startup scouting approach. Download our free Energy Innovation Report for a broad overview of the industry or get in touch for quick & exhaustive research on the latest technologies & emerging solutions that will impact your company!

![Dive into the Top 10 Energy Industry Trends and Innovations [2025]](https://www.startus-insights.com/wp-content/uploads/2025/03/Energy-Trend-SharedImg-StartUs-Insights-noresize-420x236.webp)