Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the materials sector. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 5 promising chemical vapor deposition (CVD) solutions.

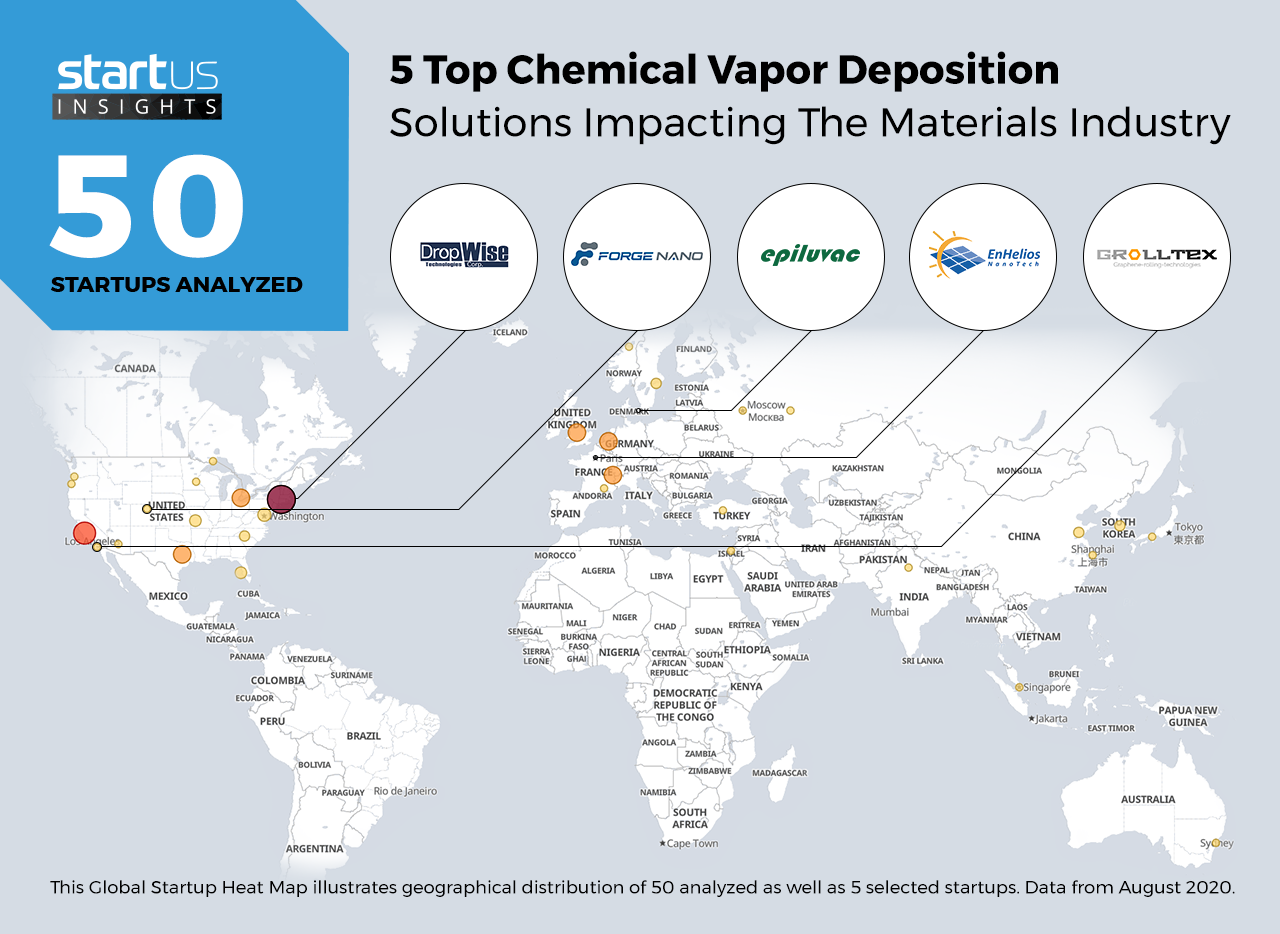

Heat Map: 5 Top Chemical Vapor Deposition Solutions

Using our StartUs Insights Platform, covering 1.116.000+ startups & emerging companies, we looked at innovation in the field of materials. For this research, we identified 50 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and relevance of technology among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & emerging companies developing chemical vapor deposition solutions. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 50 companies we analyzed for this specific topic.

Grolltex – Graphene Manufacturing

Chemical vapor deposition creates thin layers of materials that possess uniformity, imperviousness, and purity. Current innovations in materials, including high-quality graphene rolls and thin films, are essential in high-performance electronics, displays, and sensors. CVD also enables the manufacture of products with a uniform thickness of a single atom across the entire surface, in a cost-effective manner.

The US-based startup Grolltrex is a manufacturer of single-layer graphene and boron nitride sheets. The startup creates single-layer graphene sheets using a patented transfer and processing chemical vapor deposition method. This method allows Grolltrex to create high-performance graphene products, in addition to offering them at lower costs.

DropWise – Polymer Thin-Film Coatings

Chemical vapor deposition is used to produce high-performance and high-quality materials that require high precision in their production process, such as in thin-films. By combining thin-films with various polymers, CVD provides opportunities for emerging startups to create novel materials. Polymer films are highly versatile materials that find applications in protective and functional coatings, bio-surfaces, microfluidics, sensors, adhesion, and lubrication and friction modification, among others. This further helps advance developments in the field of nanotechnology and biomedical applications.

The US-based startup DropWise is a specialist in creating functional polymer thin-film coatings using chemical vapor deposition. DropWise helps eliminate some of the challenges facing traditional CVD processes in terms of precision by deploying their non-line of sight coating method. This low-temperature and solvent-free coating process later allow for creating substrates that respond to changes in temperature or chemical composition.

Epiluvac – Gallium Nitride (GaN) & Silicon Carbide (SiC) Deposition

The semiconductor industry is moving towards the use of SiC and GaN as potential replacements for current silicon-based materials. SiC and GaN semiconductors, in particular, are able to sustain higher voltages and frequencies in electronics products. This encourages materials startups to provide efficient CVD systems tot rapidly and efficiently produce SiC and GaN semiconductors.

Swedish company Epiluvac designs and manufactures innovative CVD epitaxy reactors. The startup employs its patented cross-flow design to improve gas flow concentration on the substrate, further minimizing unwanted deposition. This solution alleviates some of the challenges related to hot-wall CVD systems by reducing the time spent on reactor maintenance. Epiluvac’s CVD epitaxy reactors for SiC and GaN offer high uniformity, modular design, automation, and are suitable for research and development (R&D) purposes.

Forge Nano – Particle Atomic Layer Deposition (ALD)

The use of chemical vapor deposition is rapidly growing across many industries owing to its precise material deposition. Moreover, the technology also enables the development of new and innovative manufacturing processes. However, most CVD systems are currently designed for highly specialized applications. Emerging startups are building suitable CVD systems to enable large-scale commercial manufacturing.

The US-based company Forge Nano is a manufacturer of particle ALD systems for large-scale commercial applications. The startup employs proprietary high-throughput processes to scale nano-coating control and surface engineering for its clients. This ALD system is utilized to improve a range of materials including powders, flats, and other objects. Forge Nano’s CVD systems further provide benefits in terms of material handling and coating. For example, in developing air-sensitive materials, electrodes used in electronic devices, and hygroscopic halide-based materials, among others.

Enhelios – Spatial ALD Thin-Film Printer

The growing popularity of renewables, particularly solar energy, is driven by the decreasing cost of efficient solar energy harvesting systems. The continuous improvement in the cost-to-performance ratio of photovoltaics (PV) is due to the R&D efforts of companies in the field of deposition technology. Advancements in CVD techniques create opportunities for startups to redesign manufacturing processes and also to scale and optimize products for high-performance.

French startup Enhelios utilizes spatial ALD to build thin-film printers that integrate passivation and capping layer deposition and contact opening. The startup’s modular thin-film printers process one or multiple wafers per printing head, depending on its application in R&D or production. EnHelios’ printers enable high-throughput layer deposition with micrometer-scale pattern resolution. This technology finds applications in photovoltaics, electronics, sensors, and optics, among others. For example, the startup’s printers create rear-passivated solar cells (PERC), eliminating the need for using multiple equipment or processes for its production.

What About The Other 45 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence that enables you to achieve your goals faster. The 5 chemical vapor deposition solutions showcased above are promising examples out of 50 we analyzed for this article. To identify the most relevant solutions based on your specific criteria, get in touch.