Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on innovative engineering solutions. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, you will discover 5 promising nondestructive testing solutions.

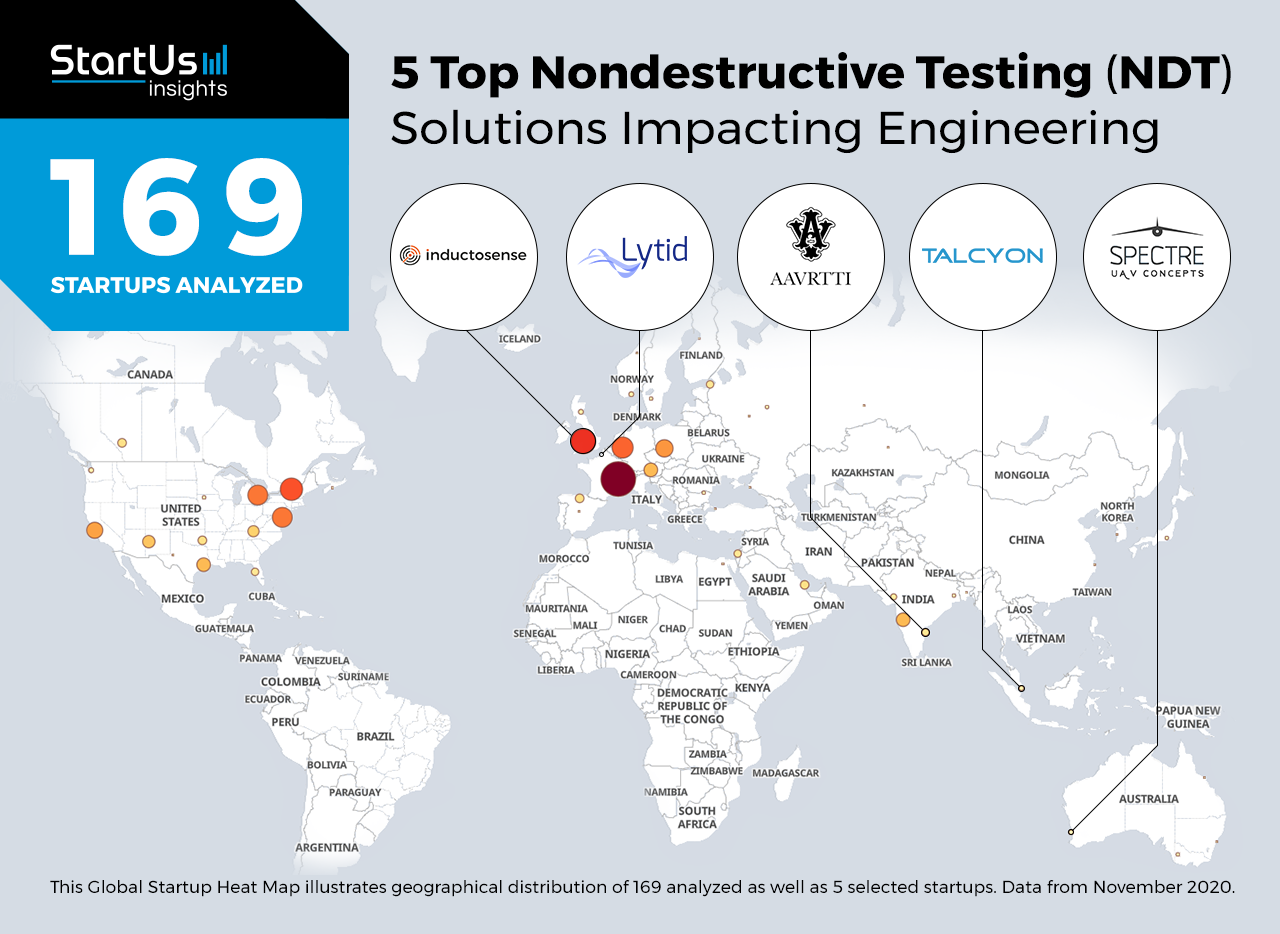

Heat Map: 5 Top Nondestructive Testing Solutions

Using the StartUs Insights Discovery Platform, covering 1.379.000+ startups & scaleups globally, we looked at innovation in the field of engineering. For this research, we identified 169 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and relevance of technology, among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & scaleups developing nondestructive testing solutions. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 169 companies we analyzed for this specific topic.

AAVRTTI – Ground-Penetrating Radar (GPR)

Ground-penetrating radar is a nondestructive testing technique of non-metallic structures. GPR uses electromagnetic waves that penetrate into the surface of the object to obtain signals that are then studied by means of an antenna moving along the surface. The practical engineering applications of GPR makes it a better technique for NDT when compared to the traditional tests for reinforced concrete, such as rebound hammer tests or ultrasonic pulse velocity tests. Emerging companies are utilizing GPR to improve the quality of geophysical, engineering, and environmental surveys.

AAVRTTI is an Indian startup working on nondestructive testing solutions using ground-penetrating radar-based techniques. The startup offers its flagship product RUDI – Radar for Utility Detection and Imaging – to detect, identify, and map buried utilities. AAVRTTI also provides other services including inspection, detection, and monitoring of underground pipe leakage, localization of cable fault, as well as identification of dead and live sub-surface cables.

Spectre UAV Concepts – Infrared Thermography

Infrared thermography uses infrared cameras for NDT and nondestructive evaluation (NDE). While monitoring the differences in surface temperature, thermal imaging is capable of detecting subsurface defects and anomalies. The key advantage of infrared thermography is the ability to scan large areas with great speed and efficiency. Infrared thermography is also risk-free since it does not emit any harmful radiation.

Australian Spectre UAV Concepts offers NDT and asset inspection services using infrared thermal imaging. The startup’s forward-looking infrared (FLIR) sensors are fit onto heavy-lifting drones to offer aerial thermal imaging. The drone then monitors the health of solar power plants and the related infrastructure in hazardous environments. This real-time solution significantly reduces the inspection time and associated risks since it eliminates the need to erect scaffoldings or build platforms.

Inductosense – Ultrasonic Testing (UT)

Ultrasonic testing is a widely used technique for performing nondestructive testing. UT is based on the propagation of ultrasonic waves in the object or material being tested, making it possible to find flaws inside a material. Moreover, UT possesses high penetrating power and sensitivity to deliver insights into the size, orientation, shape, and nature of defects. UT is also non-hazardous to industrial operations and enables portability to provide immediate test results.

Inductosense, a British startup, creates solutions in NDT using ultrasonic testing. Inductosense manufactures ultrasonic sensor technology to enable accurate monitoring of internal corrosion & erosion in pipelines and vessels. The startup’s patented, battery-free sensor, WAND, is deployable in volumes and proves useful when monitoring. WAND ultimately helps engineering companies reduce manual intervention and costs.

Lytid – Terahertz Technology

Terahertz (THz) imaging, an emerging NDE technique, is useful for analyzing dielectric materials to improve quality control in the pharmaceutical, biomedical, security, materials, and aerospace industries. The use of THz waves for nondestructive evaluation enables inspection of multi-layered structures. These waves also identify abnormalities from foreign materials, dis-bonding and delamination, mechanical impact damage, heat damage, and water or hydraulic fluid ingression. Unlike X-rays, THz waves have no ionizing effects and are generally biologically benign.

French startup Lytid provides solutions in the field of NDT using terahertz technologies. The startup’s proprietary solution, TeraSchottky, is a compact, user-friendly, and fully-integrated sub-terahertz source that allows for high-resolution THz spectroscopy and high penetration THz imaging. The startup offers sub-THz components that use Schottky diodes, THz sensors, and infrared detectors, among other products. TeraSchottky is a plug-and-play system with a remote controller.

Talcyon – Acoustic Pulse Reflectometry (APR)

APR inspection systems are an advanced and innovative tool in the field of NDT that uses acoustic waves to evaluate the integrity of tubes. APR combines computerized inspection systems and advanced software. For example, APR accurately detects internal tube flaws such as holes, leakages, blockages, erosions, and pitting. APR-based NDT potentially meets the industry demand for speed, accuracy, and objective report generation.

Talcyon is a Singapore-based startup utilizing its patented APR technology to develop a tool to overcome the limitations of conventional inspection techniques. With its simple operation, interactive analysis, and report generation, APRIS offers an enhanced user experience during the testing phase. The APRIS tool is reliable for quickly inspecting even the more challenging tube sizes and configurations. APRIS also increases the inspection cycle efficiency while reducing operational costs.

What about the other 164 solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence and enable you to achieve your goals faster. The 5 nondestructive testing solutions showcased above are promising examples out of the 169 we analyzed for this article. To identify the most relevant solutions based on your specific criteria, get in touch.