Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into Industry 4.0. This time, you get to discover 5 hand-picked startups offering optimization technologies for process industries.

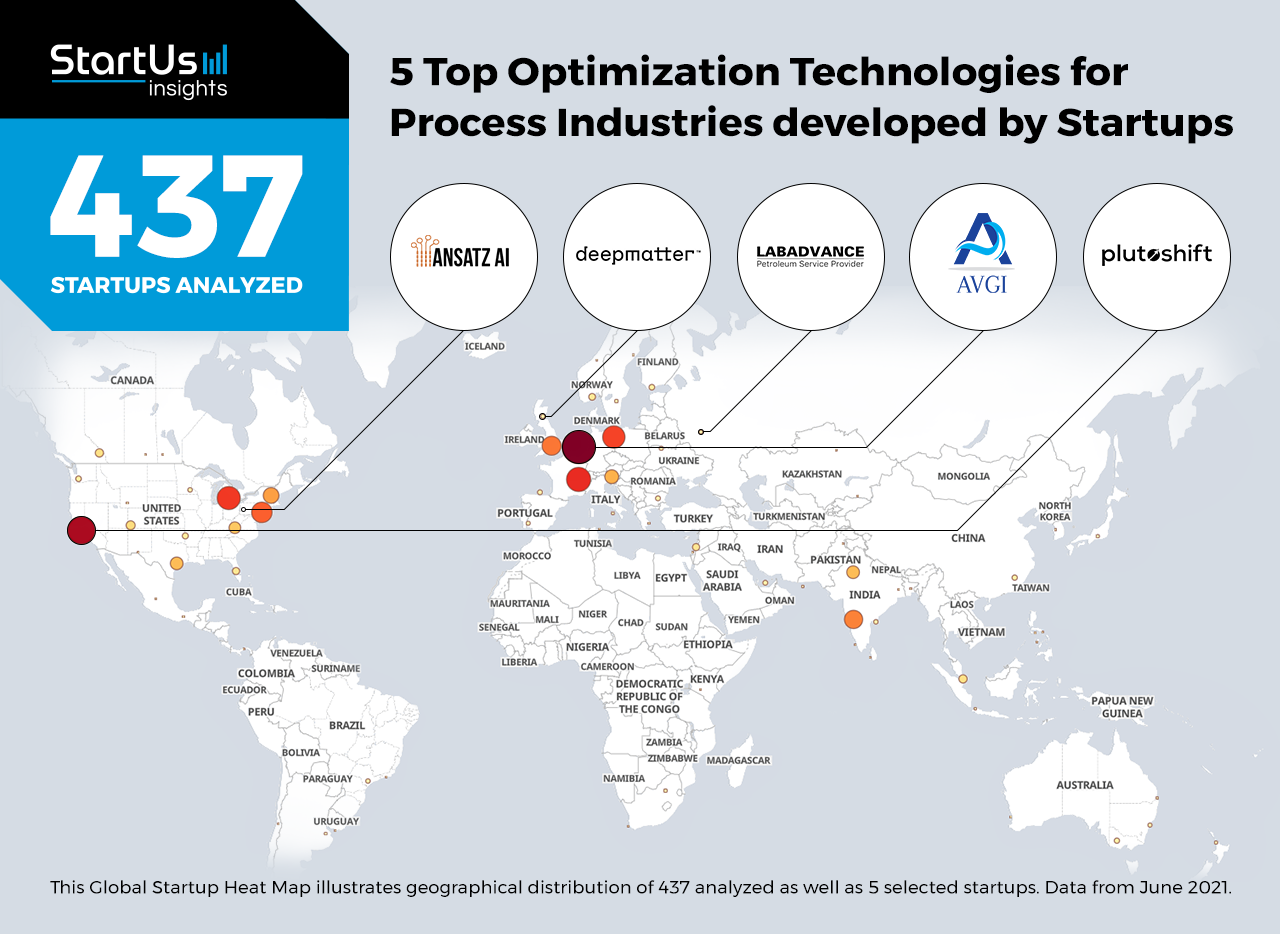

Global Startup Heat Map highlights 5 Top Optimization Technologies for Process Industries out of 437

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 437 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 startups developing optimization technologies that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 432 optimization solutions for process industries, get in touch.

AVGI provides a Reactor Simulation Platform

The steam cracking process used by petrochemical industries to produce lighter alkenes is quick. Since the process utilizes an array of boundary conditions, feedstocks, and temperature profiles, discovering the optimum choice becomes difficult. To solve this, startups are developing simulation tools for process and condition optimization.

AVGI is a Belgian startup that provides COILSIM1D, a simulation and optimization software for the petrochemical industry. It optimizes the process of steam cracking using accurate reactor simulations. The simulations are applicable for diverse feedstocks, reactor geometries, furnaces, and operating conditions. Combining the startup’s user-friendly software interface with its kinetic network provides valuable information. The flexibility of the platform also allows users to optimize reactor simulations with different boundary conditions, automatic or user-specified temperature profiles, feedstock reconstruction, furnace simulations, and more.

ANSATZ AI uses Hierarchical Machine Learning (HML) for Physical Systems Optimization

Industries such as cosmetics, agrochemicals, and nanomaterials involve complex physical methods. The development process of these is resource-intensive and often leads to non-optimal solutions. This also increases the cost and time consumed. To solve challenges facing physical systems, startups are developing artificial intelligence (AI)-based solutions.

US-based startup ANSATZ AI uses HML algorithms to optimize complex physical systems. The algorithm enables formulation and reformulation for the cosmetics and personal care, paint, and cement industries, as well as production systems. Further, the complex combinations of underlying chemistries make it difficult to optimize the processes which require simultaneous refinement of materials and formulations. HML, on the other hand, predicts relevant synergies using small datasets, leading to active optimization that saves time and development costs for manufacturers.

Plutoshift offers Automated Performance Monitoring

With the transition towards industry 4.0, enterprises are facing difficulties digitalizing manufacturing processes. Digital manufacturing and production processes enable prediction tools to optimize process changes. Therefore, startups are developing solutions to automate production and manufacturing lines across industries.

Based out of the US, Plutoshift is a startup offering Grounded AI, a cloud-based platform to reduce resource consumption and operating costs. The platform provides automated performance monitoring for the food and beverage, chemicals, and manufacturing industries. For example, the platform provides predictive modeling of equipment enabling chemical industries to optimize process efficiency using custom algorithms. The platform also connects chemical inventory volumes with production systems. In addition, the platform optimizes the dosing treatment requirements for wastewater treatment plants.

Deepmatter builds a Digital Chemistry Platform

Since chemical industries require complex processes, there is a need for digital assessment of the processes. Making the same composition is difficult and different conditions result in different outcomes. To overcome this challenge, startups develop cloud-based solutions that enable reproducibility and predictability for chemicals-based industries.

British startup Deepmatter provides a cloud-based digital chemistry platform. The DigitalGlassware platform transforms chemistry into code using AI and ML to make molecules and provide insights into the compounds. The platform encodes mixtures, steps, and operations to make them reproducible and uses sensors to gather data about the chemical process. The data is then transferred to their DeepMatter cloud for further analysis. The solution enables real-time analysis of chemical reactions and the synthesis is replayed. This optimizes chemicals, materials, and formulations used by pharmaceutical research and fine chemicals, as well as scientific publications.

Labadvance optimizes Oil Recovery Methods

Oil recovery methods face major challenges in sweep efficiency, microfluidics evaluations, rock sampling, and more. This results in loss of time and also produces non-satisfactory results for petroleum operators and chemical providers. To solve this, startups are developing solutions that use artificial samples of rocks for analysis.

Labadvance is a Russian startup that optimizes petroleum services for petroleum operators and providers of upstream chemicals. The startup optimizes oil recovery methods, evaluates the efficiency of different chemicals, and performs numerical modeling of the microfluidics tests. Their solution uses artificial copies of rock samples to perform enhanced oil recovery (EOR), special core analysis (SCAL), and pressure-volume-temperature (PVT) tests efficiently. It also provides pore analysis for rocks, multiple rock cloning, and rapid visual analysis of reservoir conditions.

Discover more Industry 4.0 startups

Optimization solutions, such as the 5 examples highlighted in this report, focus on AI, IoT sensors, and advanced analytics to improve process industry performance and operations. While all of these technologies play a major role in advancing process industry operations, they only represent the tip of the iceberg. To explore more Industry 4.0 technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.