Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for Industry 4.0. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising Predictive Maintenance startups impacting industry 4.0.

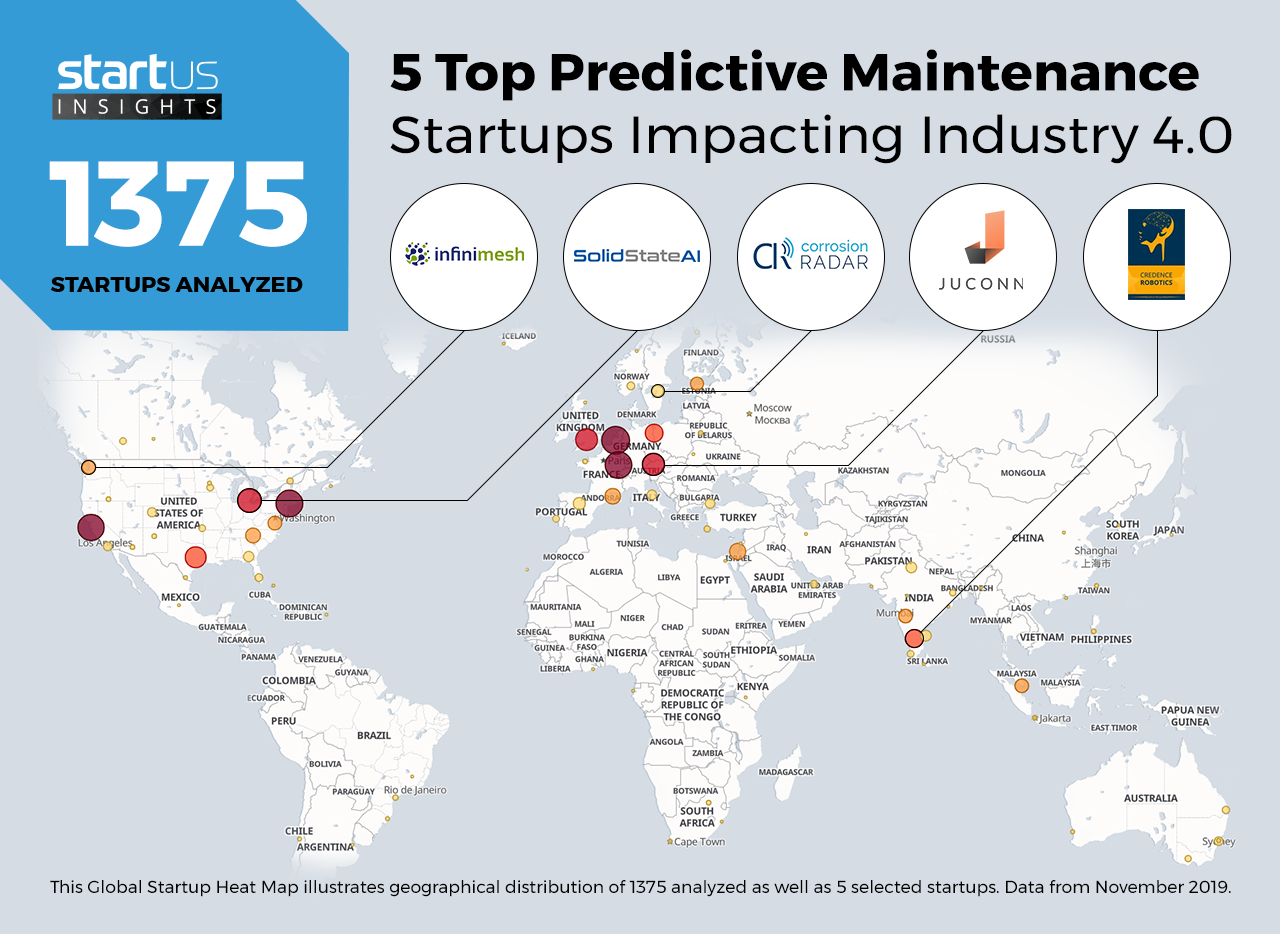

Heat Map: 5 Top Predictive Maintenance Startups impacting Industry 4.0

For our 5 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 1.375 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Infinimesh – IoT & IIoT Platform

Nowadays, as factories get more connected, they increasingly face the issue of improper data integrations. They use a mix of sensors for different equipment and purposes from different providers to track and monitor their assets. This has given rise to startups targeting seamless integrations for a factory.

The US-based startup infinimesh develops an open-source Internet of Things (IoT) and Industrial IoT (IIoT) platform to help factories integrate the vast amounts of data they collect from their machines and facilities. They provide complete asset management solutions including predictive maintenance and network security.

CorrosionRADAR – Corrosion Under Insulation

Companies with factories that operate pipelines and refineries currently spend a lot of resources to manually inspect the pipes to ensure it is fit for continued usage. Advancements in engineering and technology have enabled smart and automated inspections by using sensors that are fitted throughout the required pipelines.

British startup CorrosionRADAR designs and supplies comprehensive corrosion under insulation (CUI) monitoring solutions. Permanently embedded, distributed corrosion and moisture sensors are installed adjacent to pipelines or vessels, under any insulation. These sensors then provide real-time data on asset health with regards to corrosion or moisture presence.

Credence Robotics – Asset Health Monitoring & Prediction

There are many prerequisites that need to be met for conducting accurate predictive maintenance for the machines. One such is in asset health monitoring. This data is vital for conducting predictive analysis. Startups nowadays offer comprehensive predictive maintenance systems to help factories connect their machines in a much more meaningful way.

Indian startup Credence Robotics develops the Alphonso Predictive Maintenance System to help determine the condition of in-service equipment in order to estimate when maintenance should be performed. Such systems can help factories reduce time, costs, and asset downtime.

JUCONN – Condition Monitoring

While condition monitoring is essential to run predictive maintenance systems, it can prove to be quite useful even by itself. Condition monitoring provides factory managers with the required data at any given time, helping them plan their operations with increased efficiency.

German startup JUCONN develops complete IoT solutions including edge device management, AI / big data analytics, customized visualization and even native application development. They offer both condition monitoring and predictive maintenance solutions separately, and together.

Solid State AI – Advanced Machine Learning

Another major issue facing factories that wish to modernize their operations is productivity – for the plant, the facility or even for the workers. Lack of timely information or reactive responses to issues usually lead to asset downtime and a general drop in productivity. AI and ML techniques can greatly help factory managers understand the state of their machines and make decisions to prevent or minimize downtime.

Canadian startup Solid State AI develops advanced machine learning technologies to help the manufacturing sector. They develop an enterprise platform that enables companies to achieve higher plant yields, optimize their production tasks, and to significantly reduce asset downtime using predictive maintenance.

What About The Other 1.370 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 startups showcased above are promising examples out of 1.375 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.