Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the manufacturing sector. As there are a lot of such startups working on various different applications, we want to share our insights with you. This time, we take a look at 5 promising simulation software solutions.

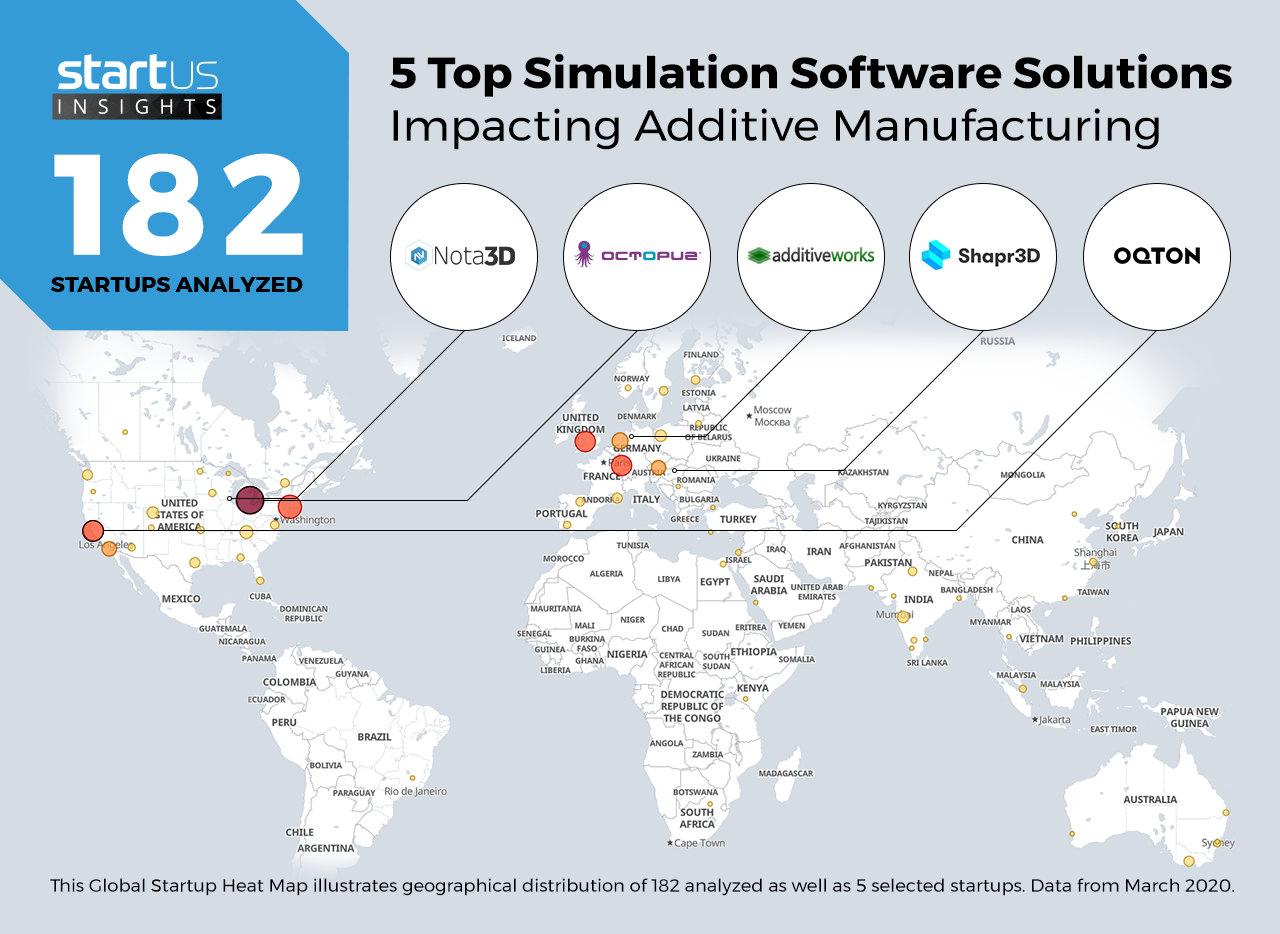

Heat Map: 5 Top Simulation Software Solutions

For our 5 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 182 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Nota3D – Additive Manufacturing Design Software

Additive manufacturing – or 3D Printing – has grown from being merely a technology for rapid prototyping to being employed in mass production. However, conventional design software does not meet the complex requirements of additive manufacturing. These include the use of support structures and part orientation, for example.

Nota3D is a US-based startup developing design and sculpting software for additive manufacturing applications. The startup’s digital design platform, Geomagic Freeform Plus, lets designers sculpt, detail, and deform virtual clay models that simulate their manufacturing needs. The solution is suitable for both rapid prototyping and low-run production.

Octopuz – Offline Robot Programming

Traditional robots usually need to be reprogrammed for each new application. Offline Programming (OLP) allows for the convenient programming of industrial robots in a virtual environment. The solution turns a simulation into a code that a robot understands, creating an easy Proof-of-Concept. This enables the configuration of multiple angle settings with appropriate end-of-arm tooling to facilitate additive manufacturing processes.

Canada-based startup Octopuz offers offline robot programming and simulation software. This enables programming path-sensitive and complex robot applications, such as those required for additive manufacturing, without disrupting manufacturing processes and or the need for an onsite expert. The solution consists of a single platform for all robot brands and allows manufacturers to validate robotic processes through simulation.

Additive Works – Metal Additive Manufacturing Optimization

Laser beam melting is the method of choice for 3D printing products that contain metals. However, sintering of the metal powder, irregular density issues, and the need to remove support structures mutually demand a lot of post-processing. This makes the process very expensive and calls for new-generation optimization software.

German startup Additive Works builds process preparation software for metal additive manufacturing. The software simulates the laser beam melting process and assesses the stress and distortion fields. In addition, it calculates the support volume required and estimates the build time for all possible orientations. Thus, it helps manufacturers choose orientations that minimize post-processing.

Shapr3D – Rapid Prototyping

3D modeling software applications are computationally intensive and have a steep learning curve. It also takes a lot of time for a design to proceed from a sketch to a prototype. Today’s intuitive solutions, often in the form of mobile apps, allow for easy design and iteration whenever and wherever needed. These technologies also enable faster design validation, making them a great tool for additive manufacturing.

Shapr3D is a Hungarian startup creating a freemium app for computer-aided design (CAD) and rapid prototyping. The startup’s solution uses a geometric modeling engine to replace clunky 3D modeling logic with an intuitive interface. The app generates manufacture-grade models and supports a large variety of file formats while it also integrates with desktop CAD applications, computer numerical control (CNC) machines, and 3D printing software.

Oqton – Additive Manufacturing Process Simulation

Additive manufacturing finds applications in Industry 4.0 to reduce the amount of unused inventory, manufacture custom parts, and rapid prototyping. Process simulation models the entire additive manufacturing process to achieve the desired product with the required parameters in the first print. As a result, it reduces overall timelines and costs, while being able to achieve complex product geometries.

Oqton is a US-based startup that offers cloud-based simulation services for additive manufacturing. The startup’s platform, FactoryOS, is an end-to-end solution for the needs of industry 4.0. The simulations are combined with Artificial Intelligence (AI) recommendations to estimate the costs involved in each step. The in-built topology optimization kernels help manufacturers design the most optimal lattices and support required for production.

What About The Other 177 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 simulation software solutions showcased above are promising examples out of 182 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.