Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights. This time, you get to discover 5 hand-picked startups building automated inspection systems.

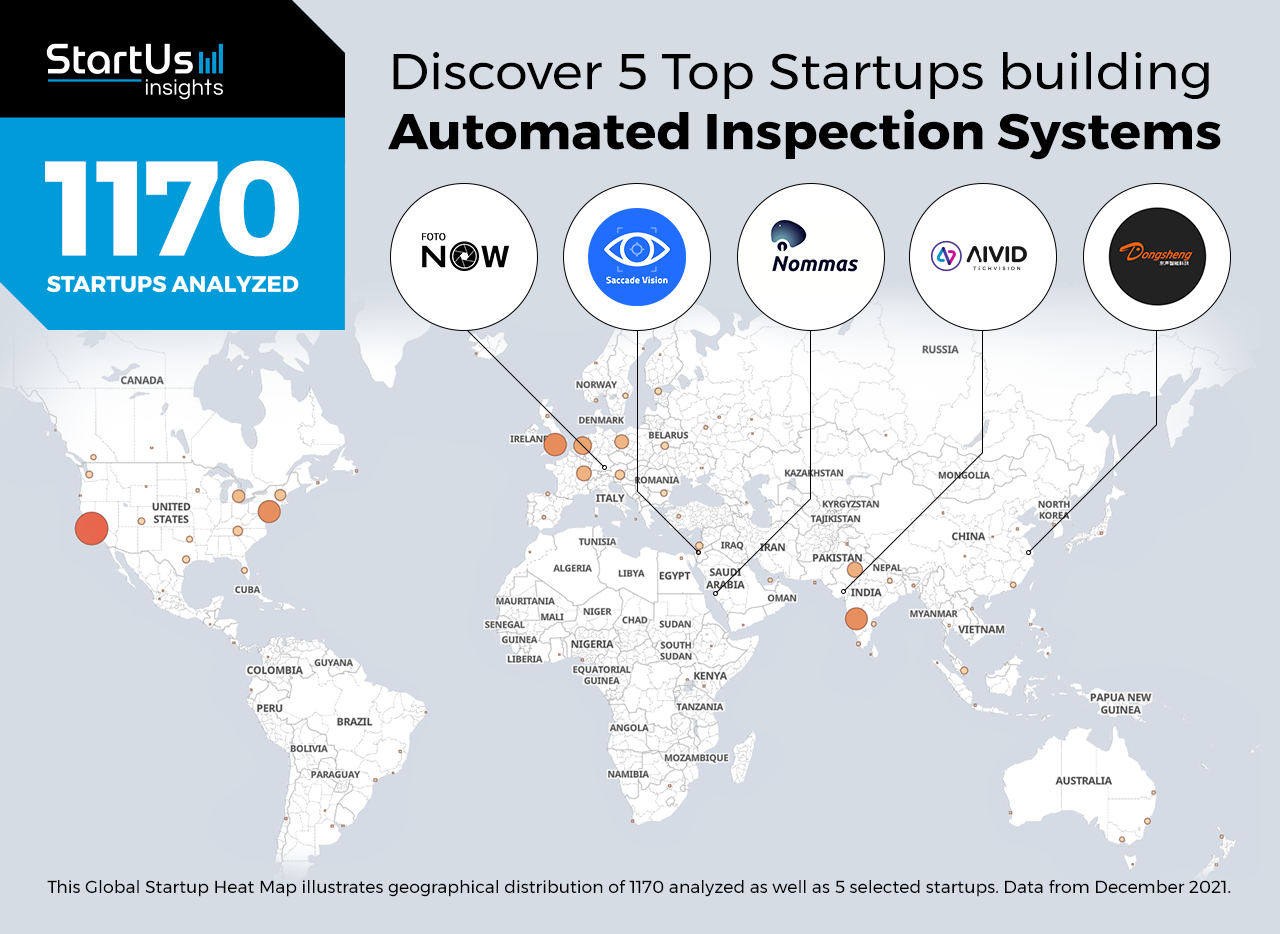

Out of 1 170, the Global Startup Heat Map highlights 5 Top Startups building Automated Inspection Systems

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 1 170 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 1 165 startups building automated inspection systems, get in touch.

AIVID automates AI-based Inspection

Founding Year: 2020

Location: Ahmedabad, India

Industries: FinTech, Retail

Partner for Human Behavior Inspection

AIVID is an Indian startup that provides an AI-based system to automate human observation-based process inspection. The startup’s platform uses AI and deep learning to automate mundane, repetitive, and manual process inspections. The platform aggregates camera feeds for automated inspection reports and enables process improvements according to real-time insights. The solution is easy to deploy and scalable to multiple locations with central control. It supports multiple deployment options like cloud-based, on-premise, and edge-based. This allows banks, hotels, hospitals, retail establishments, and smart cities to generate more value out of their video data.

Dongsheng enables Automated Quality Assurance

Founding Year: 2019

Location: Suzhou, China

Industry: Electronics

Reach out for Quality Management

Chinese startup Dongsheng develops computer vision and AI-based solutions to automate quality assurance. Handdle AI, the startup’s deep learning package, processes images to detect and classify their features without the need to design separate algorithms for specific image features. The startup’s method ensures high precision as well as improves computing speed while offering various choices of customization. The startup’s solution allows quality inspectors to identify complex defects on assembly lines.

FotoNow develops Automated Vision Inspection

Founding Year: 2019

Location: Munich, Germany

Industries: Automotive, Manufacturing

Collaborate for Assembly Line Inspections

German startup FotoNow develops a solution for the automation of visual inspections on automotive assembly lines. The startup’s platform automates inspection like parts tracking, serial number and barcode reading, and fault detection. The system automatically captures the images of parts, enhances their quality, and stores them on the cloud. It reads text, numbers, and barcodes to track and check the parts in accordance with conformity regulations. The solution also identifies scratches, cracks, blowholes, and other faults with high accuracy, which improves product quality and reduces recalls. This automates quality audits on manufacturing lines.

Saccade offers Automated Dimensional Inspection

Founding Year: 2019

Location: Rehovot, Israel

Industries: Manufacturing, Industry 4.0

Work with Saccade for Laser-based Inspection

Israeli startup Saccade develops solutions for the dimensional and targeted inspection of precise manufacturing. The startup uses a microelectromechanical systems (MEMS)-based laser inspection system that makes the inspection process faster by focusing on important locations with high quality. With variable resolution and local optimization, it enables inspection of multiple parts and processes with the same hardware. The startup’s solution ensures zero-defect manufacturing while reducing costs with process capacity improvements.

Nommas facilitates Packaged Product Inspections

Founding Year: 2019

Location: Jeddah, Saudi Arabia

Industries: FMCG, Food

Partner for Packaging Quality Control

Nommas is a startup based in Saudi Arabia that develops an AI-vision solution for packaged product inspections. The startup’s quality control system, 3EN-1, leverages machine vision and deep learning to autonomously inspect products throughout every phase of production. The autonomous machine vision system is suitable for packaging, printing, and processing in industries like food & beverages, pharmaceuticals, and consumer packaged goods. By enabling highly-accurate quality control, it ensures customer satisfaction without a team of skilled quality inspectors.

Discover more Automated Inspection Startups

Startups such as the examples highlighted in this report focus on predictive analytics, assembly line monitoring, and digital maintenance. While all of these technologies play a major role in advancing automated inspection, they only represent the tip of the iceberg. To explore more automated inspection technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download one of our free Industry Innovation Reports to save your time and improve strategic decision-making.

![AI in Agriculture: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/03/AI-in-Agriculture-SharedImg-StartUs-Insights-noresize-420x236.webp)

![AI in Automotive: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/03/AI-in-Automotive-SharedImg-StartUs-Insights-noresize-420x236.webp)