Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the BioTech industry. This time, you get to discover 5 hand-picked bioprocess engineering solutions.

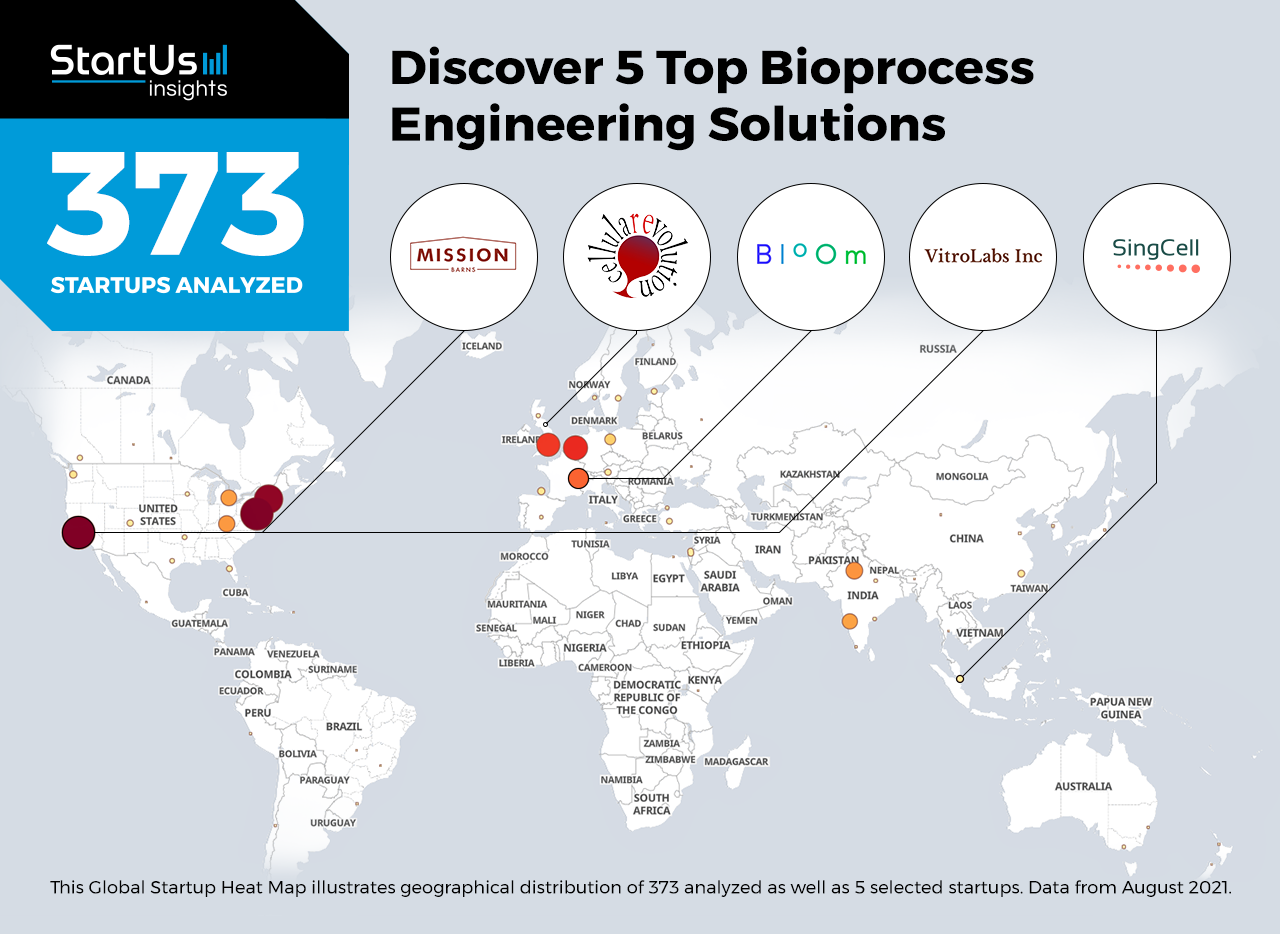

Global Startup Heat Map highlights 5 Top Bioprocess Engineering Solutions out of 373

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 373 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 BioTech startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 368 bioprocess engineering solutions, get in touch.

Mission Barns offers Cultured Meat

The meat industry is highly resource- and energy-intensive, making it unsustainable. To address sustainability as well as ethical concerns, BioTech companies are innovating with alternative meats. One of these is cultured meat that involves growing animal cells in production-scale bioreactors. To further accelerate this effort, startups are advancing bioprocess engineering to bring the costs of cultured meat production at par with traditional meat.

US-based startup Mission Barns produces cultured meat. Its process includes isolating animal cells and growing them in a cultivator that replicates the conditions inside the animal’s body. The next step involves feeding cells the nutrients that make up the composition of traditional meat, including animal fat. The startup’s solution offers a sustainable and scalable meat alternative that also prevents the risk of contaminants and foodborne illnesses.

SingCell advances Stem Cell Production

The programmability of stem cells holds promise to cure a wide range of diseases, including neurodegenerative diseases and cancers. Along with the growth of cell-based therapies and regenerative medicine, the demand for stem cells is increasing too. However, growing stem cells at scale remains challenging. This limits the wider adoption of off-the-shelf cell therapies. To address this, bioprocess engineering startups are innovating to make the manufacture of stem cells more scalable.

SingCell is a Singaporean startup that offers process development services for stem cell therapy. It uses its proprietary 3D microcarrier-based technology to grow mesenchymal stem cells (MSCs) at scale. The startup’s bioprocess capabilities also cater to allogeneic and induced pluripotent stem cells (iPSC). By providing cost-effective stem cell production, SingCell advances the potential of stem cell therapy.

Bloom Biorenewables produces Biopolymers

Many polymer materials are extracted from petroleum and its derivatives. However, in addition to the negative environmental impact of petroleum, further processing steps are polluting. Biopolymers or biomass-derived polymers offer a sustainable alternative. This is why BioTech startups are advancing technologies to extract, fractionate, and separate biopolymers from biomass.

Swiss startup Bloom Biorenewables advances fossil-free alternatives to polymers. Its aldehyde-assisted fractionation (AAF) technology enhances the separation of cellulose from biomass sources such as forestry biomass. The startup’s portfolio includes biomass-derived lignin polymers and highly crystalline cellulose for use in the pulp and paper industry. It also offers on-demand functionalization of lignin biopolymers to meet client requirements.

VitroLabs develops Lab-Grown Leather

Leather is always in high demand among consumers due to its durability and versatility. However, the industry generates large amounts of waste and raises ethical concerns similar to animal agriculture. Vegan alternatives exist, but they are petroleum-based and, thus, also unsustainable. This is why BioTech startups are combining synthetic biology and bioprocessing to create sustainable leather alternatives.

US-based startup VitroLabs leverages bioprocessing to create lab-grown leather. The startup’s process uses animal cells obtained from biopsies and grows them in a specialized bioreactor. It then provides the environment required for these cells to differentiate into an animal hide. Upon harvesting, the hides are ready for tanning without the need for any additional processing steps.

CellulaREvolution enables Continuous Bioprocessing

Unlike most process industries, BioTech and biopharma production largely use batch production instead of continuous production. Batch reactors provide low yield per unit volume, leading to a high footprint and poor scalability of bioproduction. This is why startups are developing technologies to enable continuous bioprocessing. Moreover, it enables companies to manufacture large quantities of bioproducts in smaller bioreactors.

CellulaREvolution is a British startup that works on the continuous bioprocessing paradigm. It provides two technologies that enable continuous cell culture. These include a peptide coating that allows cells to proliferate in serum-free conditions and a bioreactor that facilitates serum-free cell production. The startup’s solutions facilitate inline single-cell quality assurance (QA) as well as scale up biomanufacturing.

Discover more BioTech Startups

BioTech startups such as the examples highlighted in this report focus on fermentation, biomanufacturing, and cellular agriculture. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore more technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free BioTech Innovation Report to save your time and improve strategic decision-making.