Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the manufacturing industry. This time, you get to discover 5 hand-picked computer-aided engineering startups.

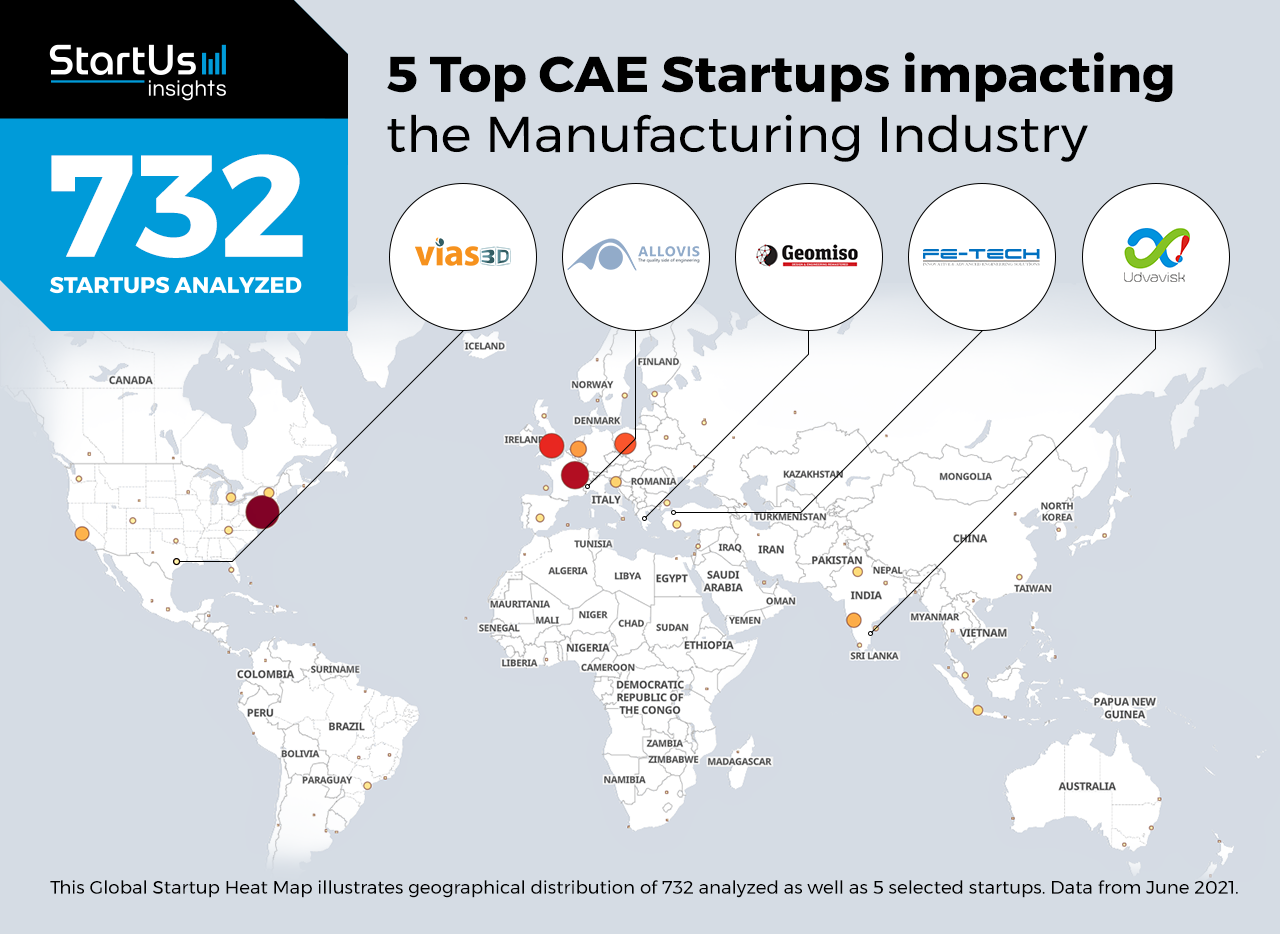

Global Startup Heat Map highlights 5 Top CAE Startups out of 732

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 732 exemplary CAE startups & scaleups we analyzed for this research. Further, it highlights 5 manufacturing startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 727 CAE startups, get in touch.

Udvavisk Technologies enables Finite Element Analysis (FEA)

Manufacturing process management typically involves large systems that consist of numerous complex equations. FEA is the practice of breaking large systems into smaller elements, called finite elements, and modeling simple equations for these elements. These equations are then aggregated to form a larger system of equations for the entire model and finally solved. FEA simulation improves insight into critical design parameters and allows for faster and cheaper prototyping.

Indian startup Udvavisk Technologies provides FEA for industrial manufacturing. The startup’s FEA service is designed to help industries solve various challenges, providing solutions by benchmarking with available data and validating results. The startup conducts structural analysis, dynamic analysis, fatigue analysis, failure analysis, and more, for industrial equipment. Udvavisk Technologies also offers implementation services and other computing technologies for equipment manufacturing.

VIAS3D provides Computational Fluid Dynamics (CFD) for Industrial Equipment

Fluid flow constitutes one of the critical factors when manufacturing a component that interacts with any sort of fluid, including water. For the successful operation of these components, accurate fluid dynamics analysis is crucial. Startups develop CFD, which digitally analyzes and solves problems involving fluid interaction. For example, CFD optimizes the efficiency of industrial fans, reduces time and cost in the design phase, and also improves the performance of products.

Based out of the US, VIAS3D is a startup performing CFD analysis for industrial equipment. The startup offers its services in design, efficiency, and performance analysis, as well as fan-curve prediction of industrial fans and blowers. VIAS3D also conducts failure and thermal analysis for fluid machinery and non-newtonian flow analysis for polymer melts and molds. The startup’s CFD solution extends machinery lifespan while reducing the time required for design and fabrication. The startup also offers FEA and electromagnetic contact and performance analysis for machinery.

FE-TECH conducts Equipment Fatigue Analysis

The challenge with machine maintenance lies in how faults develop in equipment. As machines run over long times, fatigue eventually causes them to malfunction. However, equipment often doesn’t show visible signs of fatigue during usage. This results in inefficient performance and potentially endangers human life. Startups develop fatigue analysis solutions to simulate and evaluate the lifespan of a machine. This reduces costs, downtime, and improves industrial worker safety.

FE-TECH is a Turkish startup providing fatigue analysis for industrial equipment. Through fatigue analysis, the startup evaluates system safety limits according to the number of cycles and operational load bearing. The startup achieves this by analyzing stress life, strain life, and fracture mechanics to accurately predict when maintenance or replacement is required. This technology is especially useful for automotive and machinery manufacturers. The startup also provides CAE tools for other industries such as defense, aerospace, railways, and storage tanks, among others.

Geomiso provides Isogeometric Analysis

The FEA process is limited by a lack of integration with computer-aided design (CAD) tools. Since CAE and CAD typically work in parallel, this integration is crucial for optimizing design and analysis. Because of this, startups develop isogeometric analysis tools that integrate FEA with non-uniform rational basis spline (NURBS)-based CAD tools. This integration allows manufacturers to design and test the models in the same runtime environment, lowering the manufacturing time.

Greek startup Geomiso provides isogeometric analysis services for manufacturing companies. Geomiso Terminator v1.0 is a CAE package that allows users to perform linear static NURBS-based isogeometric analysis of surfaces as well as 2D and 3D solid models. The package includes a variety of load types, boundary conditions, and tools, such as mesh refinement through knot insertion, order elevation, and k-refinement. This allows manufacturers to accurately design and produce components in a time-efficient manner.

Allovis Engineering Services utilizes Multibody Dynamics (MBD)

Most large machinery consists of several interconnected components, which are both rigid and flexible. The interaction between these components needs to be analyzed and mapped for effective manufacturing. Startups achieve this through MBD, which analyzes the relationships and interactions between different components in the equipment. For example, MBD is used to design and manufacture planetary stranding machines, which consist of multiple component interactions. MBD ensures exhaustive evaluation of equipment, machine, or vehicle to increase durability and reduce maintenance costs.

Allovis Engineering Services is an Italian startup that utilizes MBD kinetic-dynamic analysis for mechanical assemblies. The startup uses a multi-flexible-body-dynamics software, RecurDyn, to analyze the dynamic behavior of flexible bodies in complex systems. RecurDyn includes complete management of the mesh and integrates scripts for automating sequential processes and enables testing of product configurations in the pre-design phase. The startup also provides other CAE services, such as CFD and FEA.

Discover more Manufacturing Startups

Manufacturing startups such as the examples highlighted in this report focus on quality management, metal laser sintering, and manufacturing execution systems. While all of these technologies play a major role in advancing the manufacturing sector, they only represent the tip of the iceberg. To explore more manufacturing technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Manufacturing Innovation Report to save your time and improve strategic decision-making.