Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into Industry 4.0. This time, you get to discover 5 hand-picked heavy industry inspection startups.

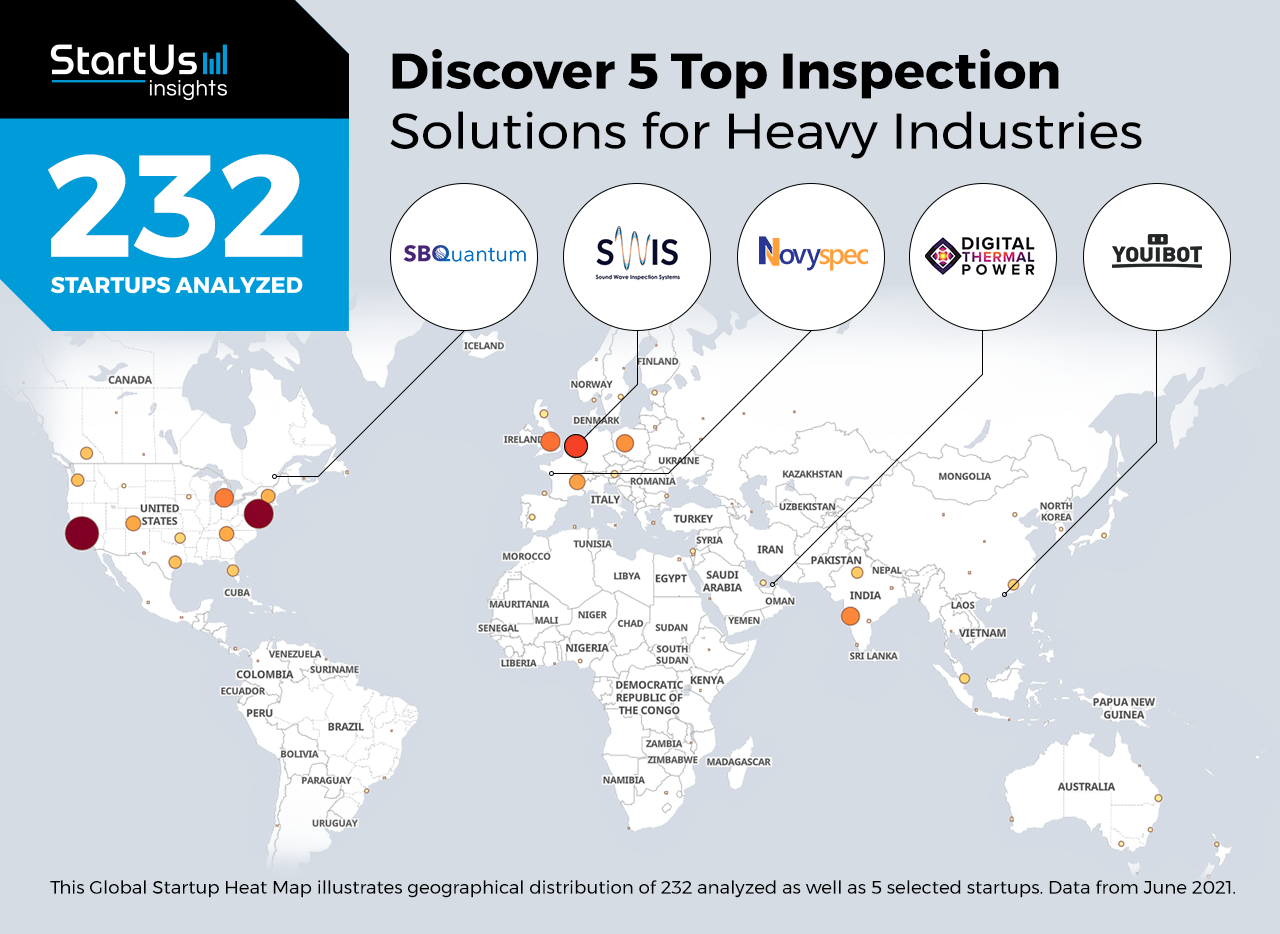

Global Startup Heat Map highlights 5 Top Heavy Industry Inspection Startups out of 232

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 232 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 heavy industry inspection startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 227 heavy industry inspection solutions, get in touch.

Digital Thermal Power builds a Gas Leak Detection System

For heavy industries, immediate detection of faults and malfunctions of equipment is important. Early detection of leakages and faults greatly reduces the risk of injury to workers, as well as the degrading effects on the environment. The change in temperature of the equipment or its surrounding is a major indicator of these defects. This is why startups are utilizing thermal imaging techniques for fault detection.

Digital Thermal Power is a UAE-based startup that utilizes infrared imaging technology for leakage and failure detection. IRGas Retina is the company’s gas leak detection solution that uses a drone with an infrared camera and optical gas imaging (OGI) technology. Moreover, the solution visualizes and pinpoints gas leaks without the need to shut down operations. This solution enables asset owners to detect failures and take corrective action without incurring operational losses.

Youibot provides Robotic Inspection for High-Risk Environments

Processes in heavy industries, such as mineral refining and metal production, operate under very harsh conditions. And so, manual monitoring of smelting furnaces and reaction chambers, while they are in operation, pose a safety risk. Startups develop remote maintenance solutions that monitor the condition of smelters and boilers without shutting them down. Most of the development in this area focuses on the use of robots that are able to operate in harsh conditions.

Chinese startup Youibot develops robots that are capable of carrying out monitoring and inspection tasks in harsh conditions. ARIS IS is the company’s smelting chemical inspection robot that performs daily inspections of high-risk environments such as smelting furnaces and boilers. This reduces the dependence on operators and frees them for low-risk operations. The bot uses 360 degrees omnidirectional visible light and a thermal camera for real-time surveillance and temperature monitoring. In addition, deep learning algorithms allow the robots to recognize instruments and take readings. Moreover, the solution enables engineers to carry out inspections and audits of furnaces and boilers within the safety of their offices.

Novyspec enables IoT-based Inspection & Integration

Quality and machine health inspectors in heavy industries use multiple devices to inspect and monitor the wide range of equipment. Collating the data from each of these inspection devices is cumbersome and delays the analysis and decision-making process. Moreover, maintaining a historical record of parameters using conventional methods is impractical as the personnel changes affect the data. This is why startups are developing software solutions that record these parameters efficiently.

Novyspec is a French startup that provides an IoT integration platform for inspection devices in factories. The software checks that the service follows a certain number of rules so that any anomalies are brought to light. The solution gathers data from various inspection points and generates emails, reports, and analyses. Novyspec also organizes inspections, setup user actions, and permissions. The cloud-based system allows multi-inspector teams to easily access data without having to rely on a particular individual. This further helps in the free flow of data the engineers require for fast decision-making.

SWIS develops Sound Wave Inspection Systems

Heat exchangers, coolers, boilers, or other heavy equipment with tubes experience wear and tear over the years. Defects like pitting, blockages, holes, and cracking result in a reduction in process efficiency. The existing techniques are time-consuming and increase operating costs. And for inspection, only sampling is done to get a general view of the status of the equipment. So startups are developing methods to make the inspection process faster and more efficient.

Dutch startup SWIS uses acoustic pulse reflectometry (APR) technology for inspecting tube applications. Sonic V is an APR inspection system that enables fast and reliable inspections of the tubes’ inner diameter. The device uses acoustic pulses propagated through the air enclosed by a tube to generate echoes due to defects that get recorded by sensitive microphones. Sonic V is lightweight and a battery-operated probe that is small enough to be carried in a backpack. The solution also offers a cloud-based data delivery system that helps engineers make quick decisions during a shutdown or emergency inspection.

SBQuantum utilizes Quantum Magnetometry

Heavy industries rely on a large number of underground or undersea infrastructure, either for obtaining raw materials or for the transportation of final products. Any damage to these concealed structures incurs high financial and environmental costs for asset owners. That is why heavy industry startups are developing inspection solutions for efficient monitoring of concealed infrastructure. Quantum magnetometry techniques show great promise in obtaining magnetic intelligence and visualize localized magnetic fields to inspect, explore, and navigate underground resources.

SBQuantum is a Canadian startup that uses quantum magnetometry technology to provide inspection solutions for underground or undersea infrastructure. The solution exploits the quantum properties in nitrogen-vacancy diamonds for its sensor. This enables it to perform vector analysis with a high degree of sensitivity while remaining durable and power-efficient while avoiding the need for careful orientation. SBQuantum’s algorithm computes vectorial data to determine the concealed object’s size, orientation, material, and distance from the sensor. Further, the compact nature of the sensor makes it suitable to fit on drones, rovers, or autonomous underwater vehicles. This provides greater efficiency in the remote inspection of concealed infrastructure.

Discover more Industry 4.0 Startups

Heavy industry inspection startups, such as the 5 examples highlighted in this report, focus on leak detection, sound & sensor-based inspection systems, as well as quantum magnetometry solutions. While all of these technologies play a major role in advancing safe and accurate inspections, they only represent the tip of the iceberg. To explore more industry 4.0 technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.

![AI in Automotive: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/03/AI-in-Automotive-SharedImg-StartUs-Insights-noresize-420x236.webp)