Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into Industry 4.0. This time, you get to discover 5 hand-picked optimization solutions for heavy industries.

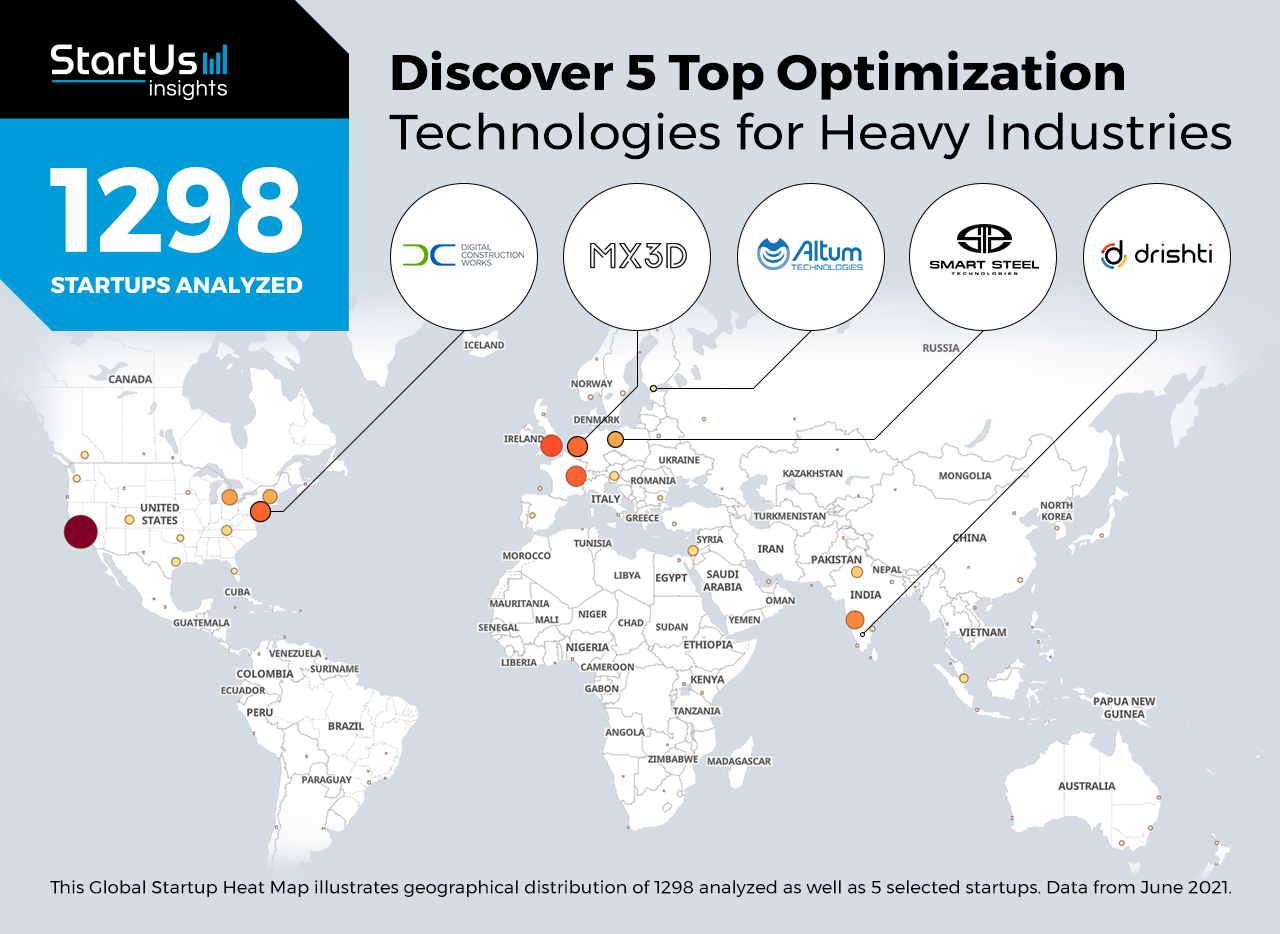

Global Startup Heat Map highlights 5 Top Optimization Startups for Heavy Industries out of 1.298

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 1.298 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 optimization technology startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 1.293 optimization solutions for heavy industries, get in touch.

Smart Steel provides a Chemistry Platform for Steelmaking

Managing temperature predictions in the steelmaking process, among other control measures, is complex and expensive. Further, continuous casting and secondary cooling processes often face temperature variance issues that compromise the cleanliness of liquid steel processes. To overcome this challenge, startups develop artificial intelligence (AI)-based solutions that reduce temperature variance and optimize steelmaking processes in real-time.

German startup Smart Steel Technologies provides Steel AI to enhance liquid steel cleanliness. The solution ensures precise adjustment of the steel chemistry in parallel with higher alloy yield using AI and machine learning (ML) models. The platform enables automatic computation of optimal heat treatment parameters, alloy quality, and additions for steel chemistry requirements. It also simultaneously optimizes the downstream production processes. The solution allows steelmakers to reduce temperature variance permanently and react precisely to process deviations.

Digital Construction Works (DCW) optimizes Construction Processes

Construction of heavy infrastructure involves complexities at various stages, from planning to decommissioning processes. Digitizing construction processes using software platforms allows project engineers to test and simulate the construction process before earthworks begin. This reduces the risk of faults during construction and prevents unnecessary delays. This is why startups are developing solutions to digitize construction processes.

US-based startup Digital Construction Works provides automation and optimization solutions for construction operations. The startup’s Integrated Advanced Work Packaging solution enables collaborative scheduling of the construction plan. The digital construction platform streamlines asset lifecycle workflows by integrating surveying, engineering, and construction data. The solution also provides prescriptive, predictive, and descriptive data analytics to evaluate the construction plan in-depth. The solution optimizes workflows for general construction and manufacturing as well as highway and road construction, among other applications.

Altum removes Industrial Fouling using a Power Ultrasound System

The use of chemicals for removing fouling is prevalent in mining and other industrial processes. However, chemical cleaning processes of equipment compounds the hazardous working conditions for workers, apart from consuming high energy. Therefore, to optimize the cleaning process, startups are developing sustainable solutions, for example, by using ultrasound technology.

Altum Technologies is a Finnish startup that offers a software-guided power ultrasound-based system to remove fouling from industrial equipment. The solution adds a mechanical cleaning effect in the target location, in addition to current washing procedures, to optimize the performance of the equipment. It cleans cooling devices and heat exchangers that require regular maintenance. Moreover, the power ultrasound-based system improves washing performance and quality without changing any other parameters in the process. This further reduces clean-in-place (CIP) time and improves production efficiency and product quality.

MetalXL enables Process Optimization with 3D Metal Printing

Metal manufacturing currently allows only preset dimensions and compositions of metals for manufacturing applications. This limits the possibilities of testing as well as developing novel metal alloys with complex dimensions. To expand the range of metal alloys used in manufacturing plants, startups are developing additive manufacturing solutions.

Dutch startup MetalXL provides industrial 3D metal printing of large metal parts using robotic wire arc additive manufacturing (WAMM) technology. The startup’s software connects an industrial robot with a power source to convert it into an industrial-grade 3D metal printer. The solution allows calibration of new metal alloys and ensures stable printing processes and quality control. It also optimizes metal printing through continuous real-time monitoring of the printing process to ensure high-quality final products.

Drishti offers AI-based Automation for Assembly Lines

Process variation in automotive assembly lines leads to delays and inconsistency in the parts produced. With limited manpower and continuous supervision, identifying bottlenecks in variations becomes challenging. Moreover, manual supervision is inefficient for long working hours or complex assembly lines. To optimize automotive assembly lines, startups develop AI-based systems that streamline automotive assembly lines and related processes.

Drishti is an Indian startup that offers AI-based automation software for the automotive industry. The solution collects data of manual production lines using cameras at every station along the assembly line. Then, the model runs data analytics on the video data for every cycle. This optimizes processes and implements standardization of work for deviations. As a result, automotive companies minimize defects and perform root cause analysis, in turn, decreasing the time for problem discovery.

Discover more Industry 4.0 Solutions

Optimization solutions such as the examples highlighted in this report focus on improving processes for automotive, steelmaking, and construction. While all of these technologies play a major role in implementing Industry 4.0 solutions, they only represent the tip of the iceberg. To explore more optimization technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.

![AI and Business: A Strategic Guide for Industry Leaders & Corporates [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/02/AI-and-Business-SharedImg-StartUs-Insights-noresize-420x236.webp)