Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the automotive industry. This time, you get to discover 5 hand-picked automotive quality management solutions.

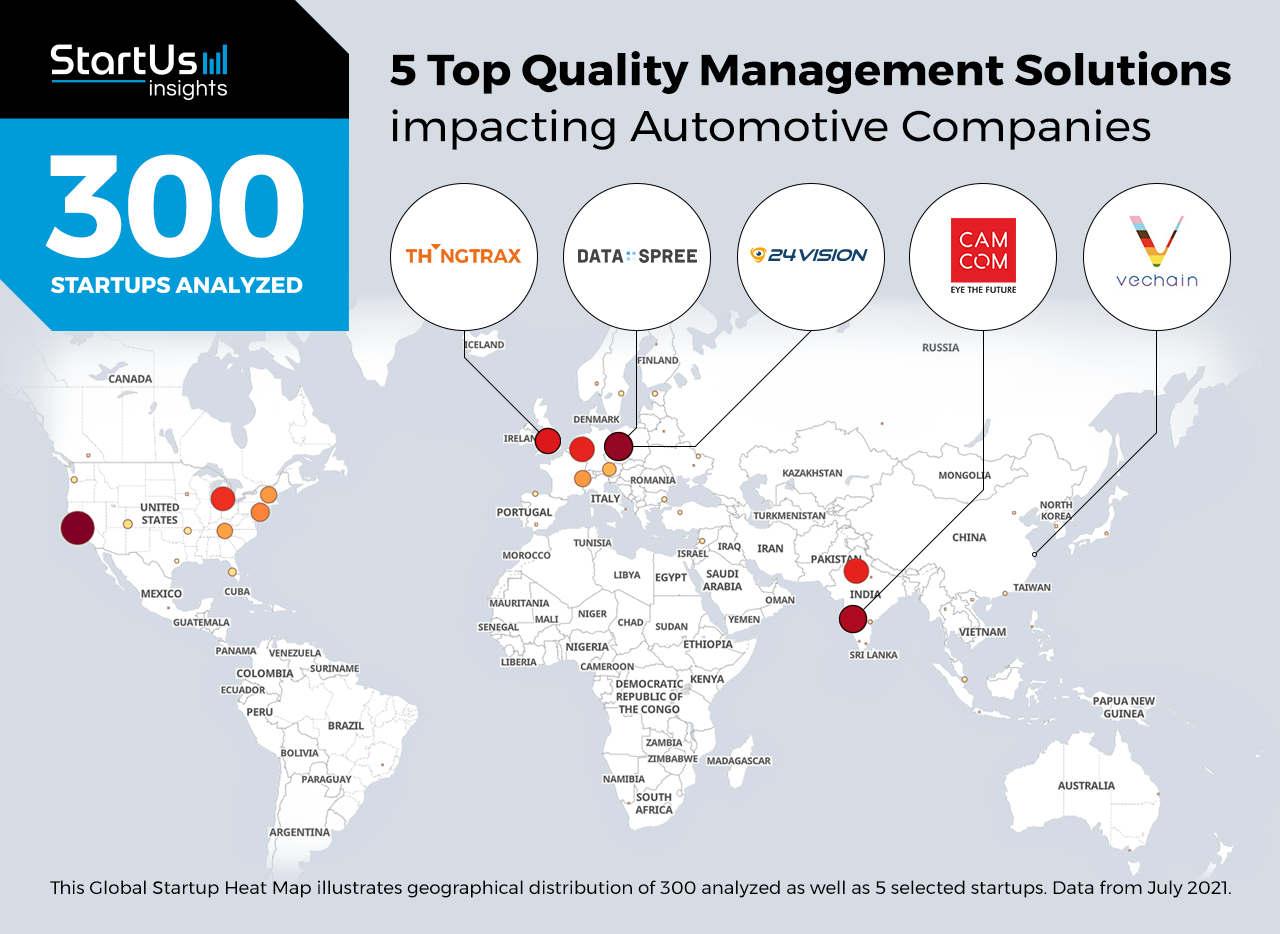

Global Startup Heat Map highlights 5 Top Automotive Quality Management Solutions out of 300

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 300 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 automotive startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 295 automotive quality management solutions, get in touch.

CamCom provides a Micro-defect Detection System

From the assembly of automobiles to rolling off the assembly line, automotive component defect detection is labor-intensive and, therefore, highly subjective and error-prone. This makes implementing quality monitoring in automotive manufacturing challenging. Thus, to optimize the quality control of automotive components, startups are developing machine-vision-based inspection solutions.

Indian startup CamCom provides an AI-based micro-defect inspection system. The startup’s solution facilitates real-time pass/fail control using machine-vision cameras and controlled lighting. The virtual system is integrable at the quality control station and provides accurate real-time defect detection for all automotive component manufacturing assembly operations. The functions are remotely configurable, providing centralized management of the distributed operations. The solution helps component suppliers reduce costs and downtime in production lines while maintaining product quality and visibility to optimize the overall process.

ThingTrax provides Automotive Manufacturing Digitization

Downtime due to machine failure or defects in the automotive manufacturing industry leads to losses. Further, using old and outdated machinery increases the frequency of downtime. The current system of periodic overhauling is inadequate to maintain the optimum condition of the machines. Therefore, startups are developing sensor-based solutions to reduce downtime and optimize the performance of mechanical systems.

British startup ThingTrax provides automotive manufacturing digitization. The startup’s solution deploys sensors to spot problems, fix machinery, and redeploy resources without significant delay in automotive manufacturing facilities. The sensors also identify energy consumption trends to enable efficient energy management. The solution facilitates data capturing from across the facility and enables predictive maintenance, energy usage analysis. This helps manufacturers to reduce downtime and improves automotive quality management by connecting machines and workers.

Data Spree provides AI-based Image Processing

Conventional rule-based image processing for defect detection in the automotive sector faces problems like interpretation variances, chaotic sorting, or false negatives. This leads to faulty and damaged parts in the vehicle, leading to a higher recall. AI-based image processing systems are flexible and adapt to multi-variant and versatile automotive production systems. Therefore, startups are developing advanced image processing solutions to improve quality assurance processes in the automotive sector.

German startup Data Spree provides AI-based image processing for efficient production and quality control in the automotive industry. The startup’s solution utilizes machine learning and integrates with existing sensors to improve the quality assurance processes. It detects and classifies different defect images from images with distinct characteristics at various manufacturing and assembly levels. This helps automotive manufacturers to react quickly and flexibly to product changes enabling quality assurance.

24 Vision offers a Quality Control System

Automotive assembly lines are difficult to manage as slight changes in machine maneuvering while assembling lead to a fault in the vehicles. If not detected during manufacturing, this results in high recall rates and incurs huge costs. The current methodologies for vehicle assembly generally lack quality management and configuration error detection. Startups are developing solutions for comprehensive quality control of production lines in the automotive sector.

Czech startup 24 Vision provides a neural network-based quality control system. The system detects defects and checks for configuration errors in vehicle parts like car seats, doors, control panels, engines, and more. The startup’s solution provides real-time comprehensive quality control of the production line and adjusts production speed. The system also collects data about the quality of each product constantly and at any location. This data enables lean analysis to find bottlenecks in production to optimize workflows.

Vechain provides Lifecycle and Quality Assessment

Lifecycle and quality assessment in the automotive industry is difficult as most of the information available is asymmetric. With stakeholders becoming increasingly proactive, there is a requirement for a tool that provides data regarding the vehicle’s lifecycle and is reliable. Therefore, startups are developing blockchain-based solutions to enable lifecycle quality assessment and authenticity in the automotive industry.

Chinese startup VeChain provides blockchain-based lifecycle and quality assessment for the automotive industry. The startup’s solution VeChainThor Blockchain assigns a unique VeChain ID and a digital passport to the vehicle. It helps automotive manufacturers to manage and trace the entire lifecycle of key components, keep track of a vehicle’s condition based on the data collected through IoT (Internet of Things) devices, as well as acquire damage information and replacement records. Moreover, the solution enables automotive manufacturers to assess the quality and authenticity of auto parts.

Discover more Automotive Startups

Automotive startups such as the examples highlighted in this report focus on robotics, lean manufacturing, as well as crash detection solutions. While all of these technologies play a major role in advancing the automotive industry, they only represent the tip of the iceberg. To explore more automotive technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Automotive Innovation Report to save your time and improve strategic decision-making.

![Essential Guide to Digital Transformation in the Automotive Industry [2025 & Beyond]](https://www.startus-insights.com/wp-content/uploads/2024/12/Digital-Transformation-in-Automotive-SharedImg-StartUs-Insights-noresize-420x236.webp)