Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into advancements in engineering. This time, you get to discover 5 hand-picked quality management solutions.

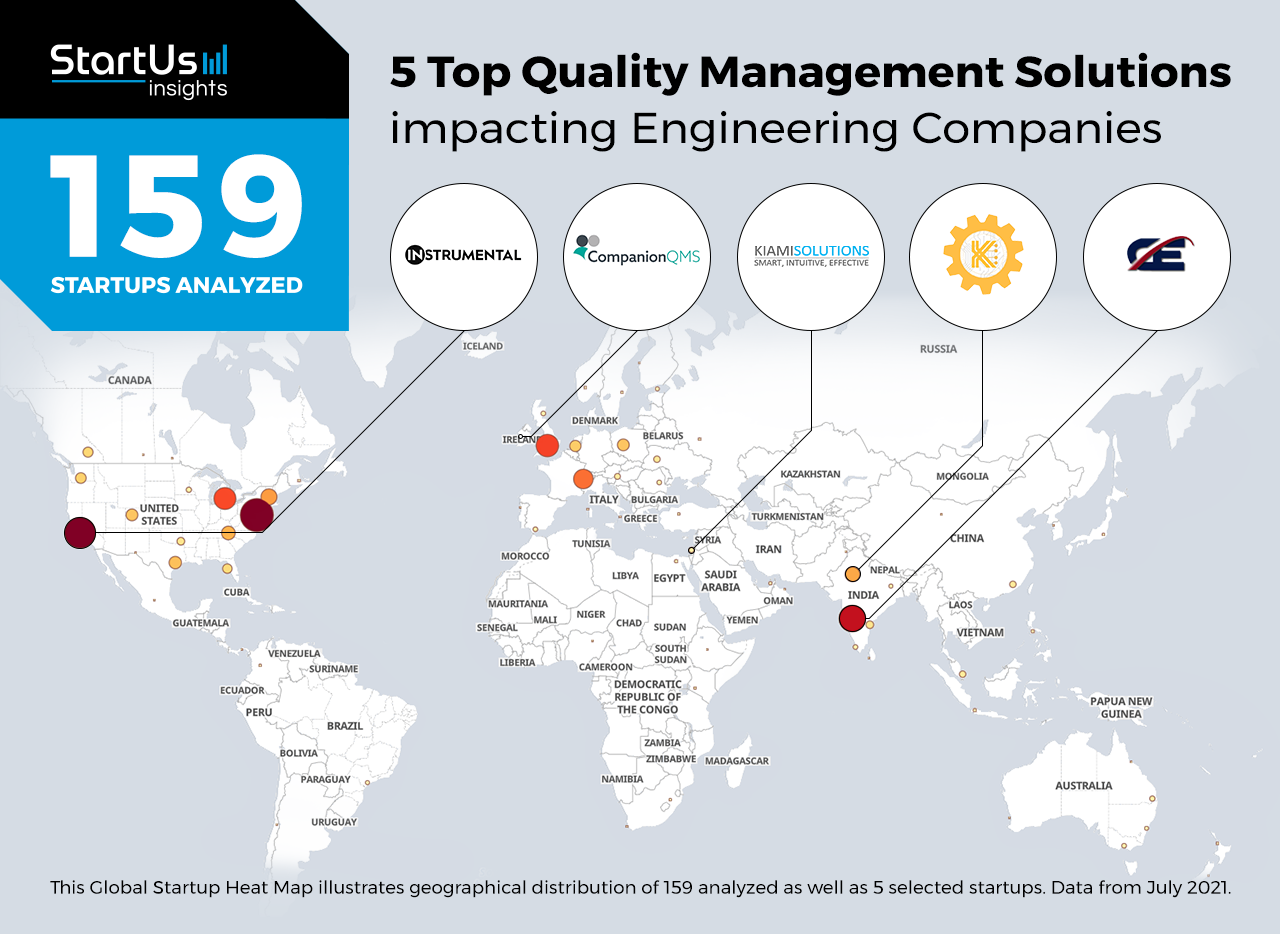

Global Startup Heat Map highlights 5 Top Quality Management Solutions impacting Engineering out of 159

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 159 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 quality management solutions that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 154 quality management solutions impacting engineering companies, get in touch.

Cutting Edge Technologies provides Quality Inspection & Analysis

Quality management provides end-to-end visibility into a product’s flow from incoming raw materials to the finished goods. This enables original equipment manufacturers (OEMs) to streamline their operations from product engineering to manufacturing. Even though quality management is associated with the production side of industries, companies now deploy quality assessments in product development as well to accelerate design finalization. Additionally, quality analyses offer extensive data on production and supply chain operations, thereby enabling quality improvements in engineering projects.

Indian startup Cutting Edge Technologies provides quality inspection and analysis. The startup uses 3D scanning to scan products and compare their specifications with the original product design. This way, engineers are able to compare their design and the final product using computer-aided design (CAD). The startup’s solution significantly reduces quality inspection periods and also provides statistical process reports. Cutting Edge Technologies further provides reverse engineering services for spare part development or improvement.

Kriptech Systems Engineering offers Quality Support

Quality management systems (QMS) assist engineers in optimizing their product designs by standardizing new product development. Additionally, QMS provides better efficiency and minimizes waste at the product development stage, further improving production efficiency. Quality management data includes customer requirements, risk analysis, supply chain information, as well as product and process errors during production. This data helps product engineers understand existing design-related issues and challenges associated with production such as sourcing and process constraints. It also establishes a feedback system to enhance product improvisation and design.

Kriptech Systems Engineering is an Indian startup that offers quality engineering support in the area of mobility as well as chemical, biological, radiological, and nuclear (CBRN) defense. The startup uses a proprietary product quality process-based design execution and technical program management to develop tailored solutions for its customers. The startup develops CBRN sensors and also creates customized solutions and accessories in the domain. Likewise, Kriptech Systems Engineering designs solutions for fire detection and suppression systems (FDSS).

Q Pathway builds a Change Control Management Platform

Product engineering unites personnel from various teams to ensure that the product meets necessary functional and quality requirements, based on testing and inspection. Therefore, engineering departments use a series of process control systems to ensure that design meets customer requirements and other regulatory compliances. QMS solutions also combine all the necessary information and reports from the latest regulatory standards to the historical inspection data. This data is critical for streamlining product design. As a result, companies minimize delays and prevent design reiteration.

Irish startup Q Pathway develops the CompanionQMS, a change control management platform for medical devices. The startup’s solution allows product engineers to impart design and process changes into existing production runs. Plus, it reduces workflow time compared to paper-based systems and is tailorable to specific business requirements. Q Pathway also provides tools for enterprise content, approval, and supplier management.

Instrumental develops a Quality Monitoring Platform

Quality management facilitates continuous improvement in manufacturing and engineering. Using continuous improvement tools in product development allows project managers to improve design efficiency and rectify wastes in the product development process. For instance, separating product management and product development based on data from QMS improves the overall efficiency of new product development. That is why startups use quality management tools throughout product engineering and manufacturing to increase productivity.

Instrumental is a US-based startup that develops a quality monitoring platform. The startup’s platform automates issue discovery, failure analysis, and quality monitoring using real-time factory floor data and artificial intelligence (AI). In effect, it allows product engineers to improve design between builds and speed up new product introduction (NPI). Instrumental’s solution is also integrable with manufacturing execution systems (MES), thereby enabling better process control.

KIAMI develops Industrial Troubleshooting Software

Quality control checks in product engineering improve overall product quality and assure regulatory compliances. This allows product engineers to finalize the design for manufacturing (DFM) without unwanted delays, thereby accelerating the time to market for new products. Therefore, companies that implement QMS-based engineering practices have a competitive advantage in the market as new products better address customer requirements, which further drives sales.

KIAMI is an Israeli startup that develops QMSexpert, a cloud-based industrial troubleshooting software. The QMSexpert combines six-sigma and lean manufacturing with smart troubleshooting. Additionally, the QMSexpert suite provides corrective and preventive actions (CAPA), new product introduction (NPI), statistical process control (SPC), and equipment monitoring systems. This enables timely detection of product weaknesses as well as equipment failures, thereby cutting down overall operational costs. The solution also identifies process challenges due to material defects and human errors.

Discover more Engineering Startups

Startups such as the examples highlighted in this report focus on quality inspection, analysis, and monitoring as well as change management and troubleshooting solutions. While all of these technologies play a major role in advancing quality in engineering, they only represent the tip of the iceberg. To explore more engineering technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download one of our free Industry Innovation Reports to save your time and improve strategic decision-making.