Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into Industry 4.0. This time, you get to discover 5 hand-picked quality management solutions.

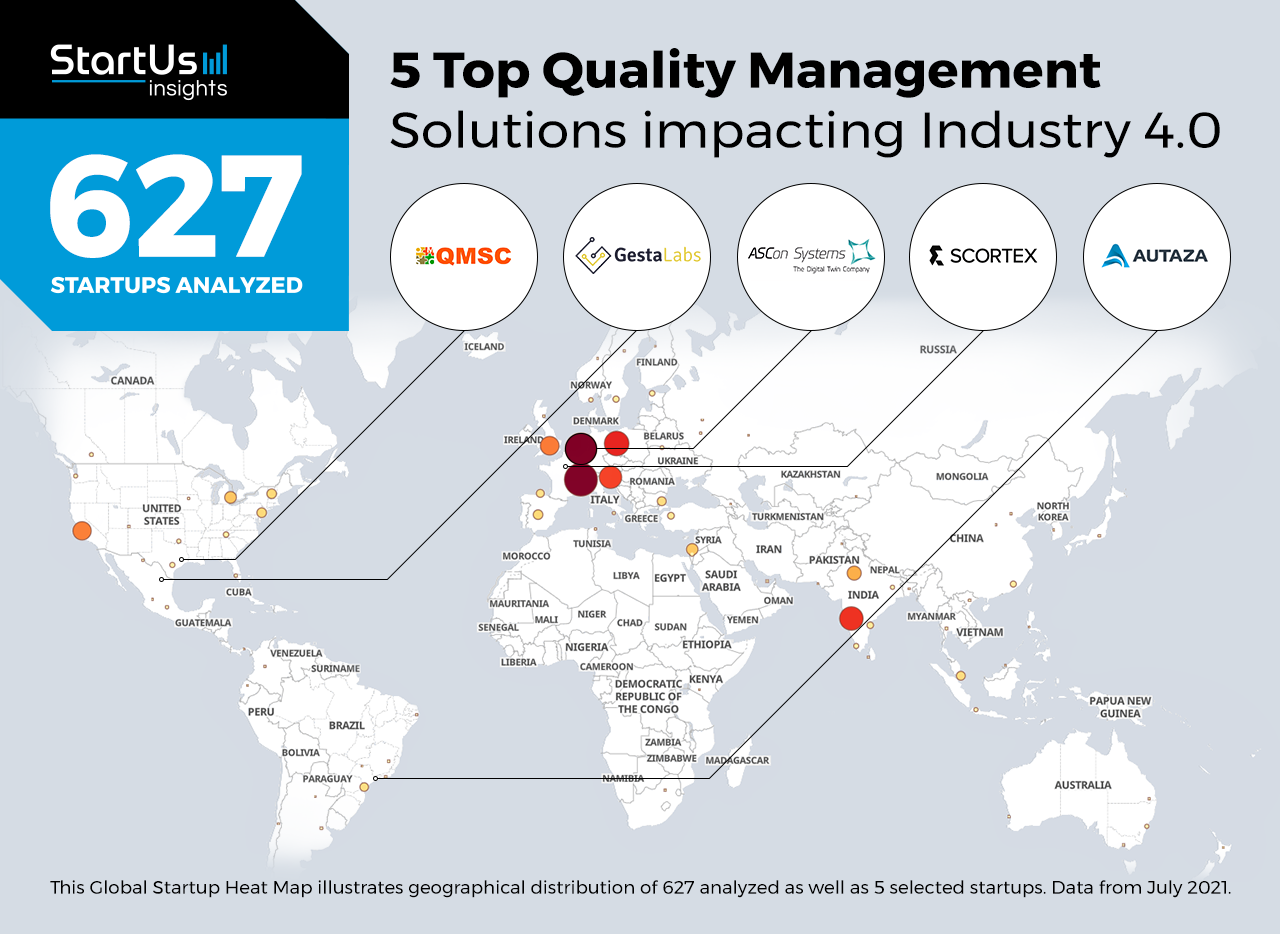

Global Startup Heat Map highlights 5 Top industrial Quality Management Solutions out of 627

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 627 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 Industry 4.0 startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 622 quality management solutions for Industry 4.0, get in touch.

QMSC enables Quality 4.0

Integrating industry 4.0 solutions into the existing production workflow provides faster means to improve productivity and obtain performance & quality data. This data further drives quality management and business decisions in the manufacturing sector. However, multiple automated systems inside a production environment cause data silos, and this leads to inefficient quality management outcomes. Startups develop centralized industry 4.0 quality management solutions to speed up quality inspections and audits, as well as facilitate collaborative working.

QMSC is a US-based startup that enables quality 4.0 using its cloud-based quality management system. The startup’s solution integrates internal and external quality data into a single point, thereby ensuring a single source of truth. The startup also uses machine learning to derive business insights from quality-related data. The startup’s solution, Core, combines calibration, document, maintenance, and audit management for better quality management. This integrated solution allows manufacturers to identify supply chain capacity and repetitive defects in the production value chain. In effect, QMSC assists manufacturing companies to decrease costs, save time, and increase revenue.

Autaza builds Intelligent Quality Control Systems

Automating production floors with robotics and artificial intelligence (AI) improves product consistency and quality as well as increases production throughput. But, using manual inspection in automated manufacturing lines slows down operations. Startups build automated quality control solutions that are retrofittable into existing machines or external solutions that are added to production lines. This way, manufacturers are able to avoid production disruption and improve quality control efficiency. Since there is no human intervention, it reduces the need for internal quality personnel and saves costs.

Brazilian startup Autaza develops intelligent quality control systems for paint defect detection, virtual surface inspection, and float glass analysis. The startup uses computer vision and artificial intelligence-based proprietary and patented technology. Also, the startup develops software and equipment for product inspection based on customer requirements. Autaza also provides special quality control projects tailored for the client’s requirements. The startup’s solutions eliminate subjectivity in defect identification and classification as well as reduces costs and ensures final product quality.

Gesta Labs creates End-to-End Industry 4.0 Solutions

A quality management system integrates solutions that improve the quality of operations throughout the production value chain. This includes processes from raw material sourcing and inventory management to new product introduction (NPI) and production runs. Quality management systems offer extensive visibility into these production operations and allow users to identify process disparities, further accelerated by real-time data points from industry 4.0 solutions. As a result, manufacturers are able to track and quantify quality metrics of production activities, thereby enabling process improvement.

Based in the US, Gesta Labs is a startup that offers end-to-end industry 4.0 solutions for manufacturers. The startup uses the industrial internet of things (IIoT), computer vision, big data, and artificial intelligence to streamline various aspects of production operations. These include inventory management, quality improvement, predictive maintenance, and production planning. All these solutions facilitate quality management in production runs, thereby improving the quality and efficiency of industrial operations. Gesta Labs further develops solutions for product optimization, demand forecasting, and energy consumption optimization, among others.

Scortex automates Visual Inspections

Visual inspection of inbound raw materials & parts from suppliers and that of the finished product is the widely used quality control process. However, manual visual inspection is prone to errors and is time-intensive. Therefore, automating visual inspection significantly improves inspection quality and production throughput. That is why startups develop visual quality control solutions using computer vision. On a more critical approach, some quality inspection systems use multiple sensors, like noise and temperature sensors, to better identify parts and products for quality deviations.

Scortex is a French startup that automates visual inspection for automotive, cosmetics, and medical device manufacturing. The startup’s defect detection and analytics platform use artificial intelligence to accurately identify defective products while improving overall plant profitability. The solution detects, labels, sorts, and acts according to the defects learned from internal quality control specialists. Furthermore, real-time and continuous data analytics assists project managers to improve processes and production, as well as enables root cause analysis with quality issue correlation.

ASCon Systems develops a Predictive Quality Assistant

Integrating AI-based solutions into end-of-line quality inspections improves inspection efficiency and overall operational performance. AI-integrated quality systems switch to a proactive quality management approach, unlike the conventional reactive systems. This allows manufacturers to predict defects with great accuracy and intervene in the process to improve the process and product quality. This reduces overall production wastage and enables continuous process improvement in product engineering and production runs.

German startup ASCon Systems develops a predictive quality assistant solution. The startup combines digital twin and quality management to monitor and continuously analyze essential process parameters and proactively identify problems. The startup’s solution collects and analyzes data from machines, enterprise resource planning (ERP) systems, and quality systems to detect anomalies. This data is then used by the solution to forecast quality variations and defects, and also notify plant managers. ASCon Systems’ product allows manufacturers to save costs due to part or product defects and reworks, thereby improving production efficiency.

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on lean manufacturing, inspection, as well as digital twins. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore more industrial technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.