Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the materials industry. This time, you get to discover 5 hand-picked startups developing use cases for rPET.

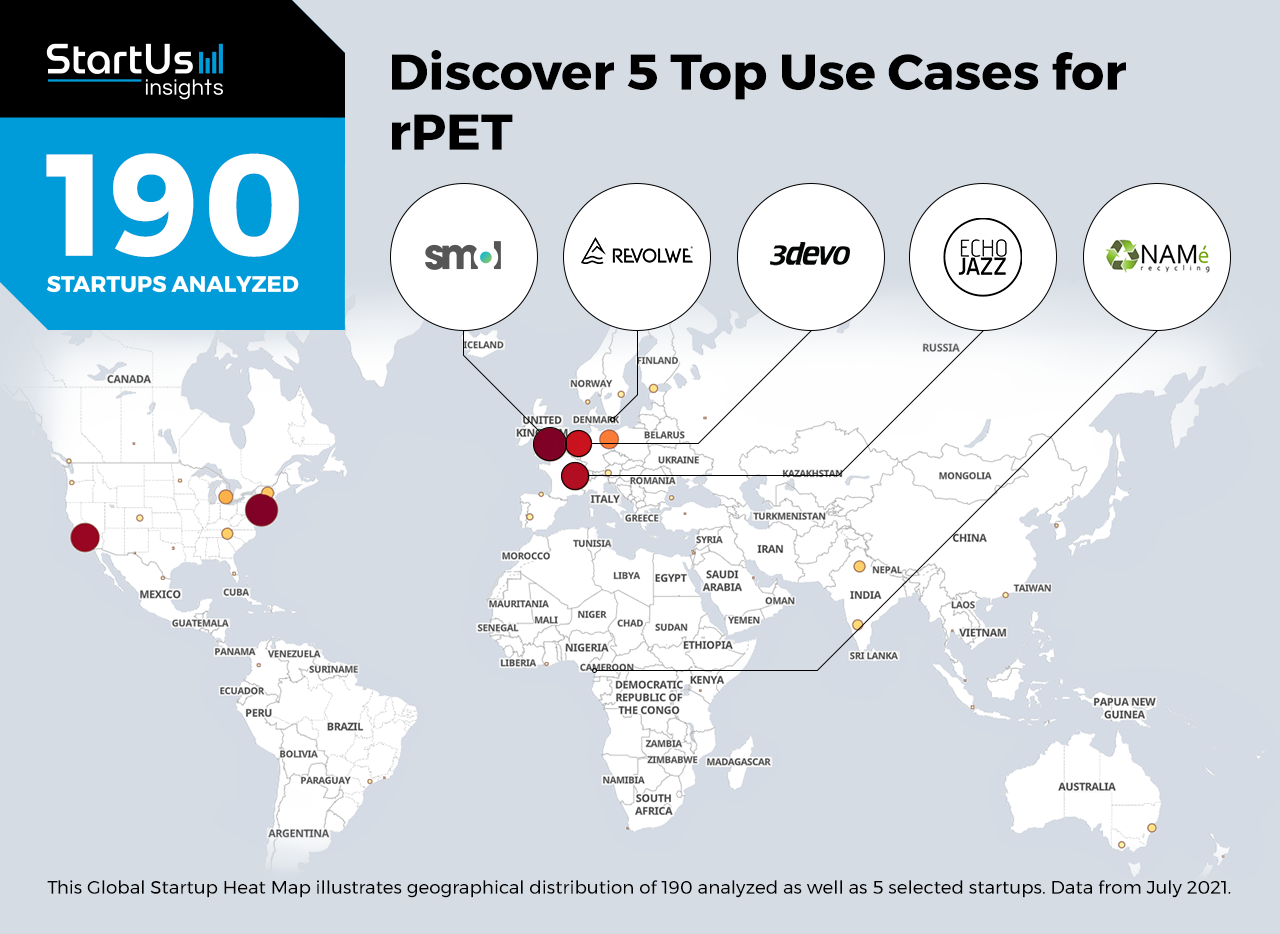

Global Startup Heat Map highlights 5 Top Startups developing Use Cases for rPET out of 190

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 190 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 materials startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 185 use cases for rPET, get in touch.

smol manufactures rPET Packaging

Plastic pollution is a major threat to marine and land ecosystems as the material takes thousands of years to degrade. A large fraction of this comes from single-use plastics made of polyethylene terephthalate (PET) and its derivatives. Efficient recycling of such plastics lowers the need for virgin plastics. This is why startups use recycled PET as an alternative to traditional plastics.

British startup smol develops sustainable packaging solutions from recycled PET. It manufactures fabric conditioner bottles using 100% post-consumer recycled plastic. The refillable cleaning bottles are also fully recyclable, further driving sustainability. Among other packaging solutions, the startup also offers laundry capsules and dishwasher tablets.

NAMé Recycling produces rPET Flakes

PET bottles are one of the most common kinds of plastic waste found in oceans. Although recycling these bottles diverts plastic from the ocean, recycling isn’t always practical in its original form. Recyclers address this by physically breaking down these bottles into flakes and preforms. This allows manufacturers to lower their carbon footprint by offering a sustainable raw material with applications across industries ranging from packaging to medical devices.

NAMé Recycling is a Cameroonian plastic recycling startup. The startup sorts, washes, extrudes, and pelletizes post-consumer plastic into recycled raw materials. It creates transparent rPET flakes and preforms ranging from 12 to 14 mm in size. It also shreds high-density polyethylene (HDPE) flakes of 6-40 mm. Thereby, the startup’s solutions reduce plastic pollution while creating local economic opportunities.

3devo offers 3D Printing Filaments

Failed 3D prints produce a lot of material waste, including plastics. Recycling this plastic waste provides an opportunity for manufacturers to close the loop locally. This is why startups are now utilizing rPET as materials for 3D printing filaments. In addition to printing waste, manufacturers also utilize PET waste from other streams for this purpose thus lowering material costs.

Dutch startup 3devo utilizes recycled plastics in 3D printing. The startup’s energy-efficient shredder, SHRE3D IT, converts unwanted plastic and leftovers from 3D prints into new filaments. After shredding, the startup melts the plastic and then extrudes filaments with precise roundness. The extrusion and spooling processes make the filament ready for 3D printing, thereby closing the loop in additive manufacturing.

ECHOJAZZ creates Acoustic Materials

Plastics find applications in the design of acoustic materials thanks to their sound-absorbing properties. However, this further increases the already high carbon footprint of construction materials. Recycled PET, on the other hand, provides similar acoustic performance while utilizing plastic waste. This is why startups are turning to rPET and its derivatives to create new acoustic materials.

Swiss startup ECHOJAZZ produces acoustic materials from recycled PET bottles. EchoCoustic, the startup’s material, absorbs 85% of the sound when applied to walls and ceilings. It is made of 100% PET, of which at least half is recycled PET. The startup also offers acoustic furniture, lighting, and walls that use EchoCoustic in its design. Further, the startup shreds any leftover plastics in their process to produce EchoFlakes, its range of rPET flakes.

Revolwe provides Sustainable Fabrics

The fashion industry is highly unsustainable in its operations. For instance, the production of synthetic fibers such as polyester involves the use of petroleum and large amounts of water. To mitigate this, there is a trend towards using recycled polyesters as sustainable fibers. This is why startups are recycling polyester fabrics as well as PET bottles into rPET-based fabrics.

Revolwe is a Swedish startup that manufactures sustainable fabrics from rPET. The startup exclusively uses recycled polyester from post-consumer PET bottles. It uses the material to create a range of sportswear apparel as well as surfing equipment. The startup also incorporates recycled cotton and nylon as well as natural fibers like bamboo and hemp in their fabrics, further advancing sustainability.

Discover more Materials Startups

Materials startups such as the examples highlighted in this report focus on additive manufacturing, lightweighting, smart materials as well as sustainability. While all of these technologies play a major role in advancing the materials industry, they only represent the tip of the iceberg. To explore more materials technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Materials Innovation Report to save your time and improve strategic decision-making.