Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the mining industry. This time, you get to discover 8 hand-picked sustainable mining startups.

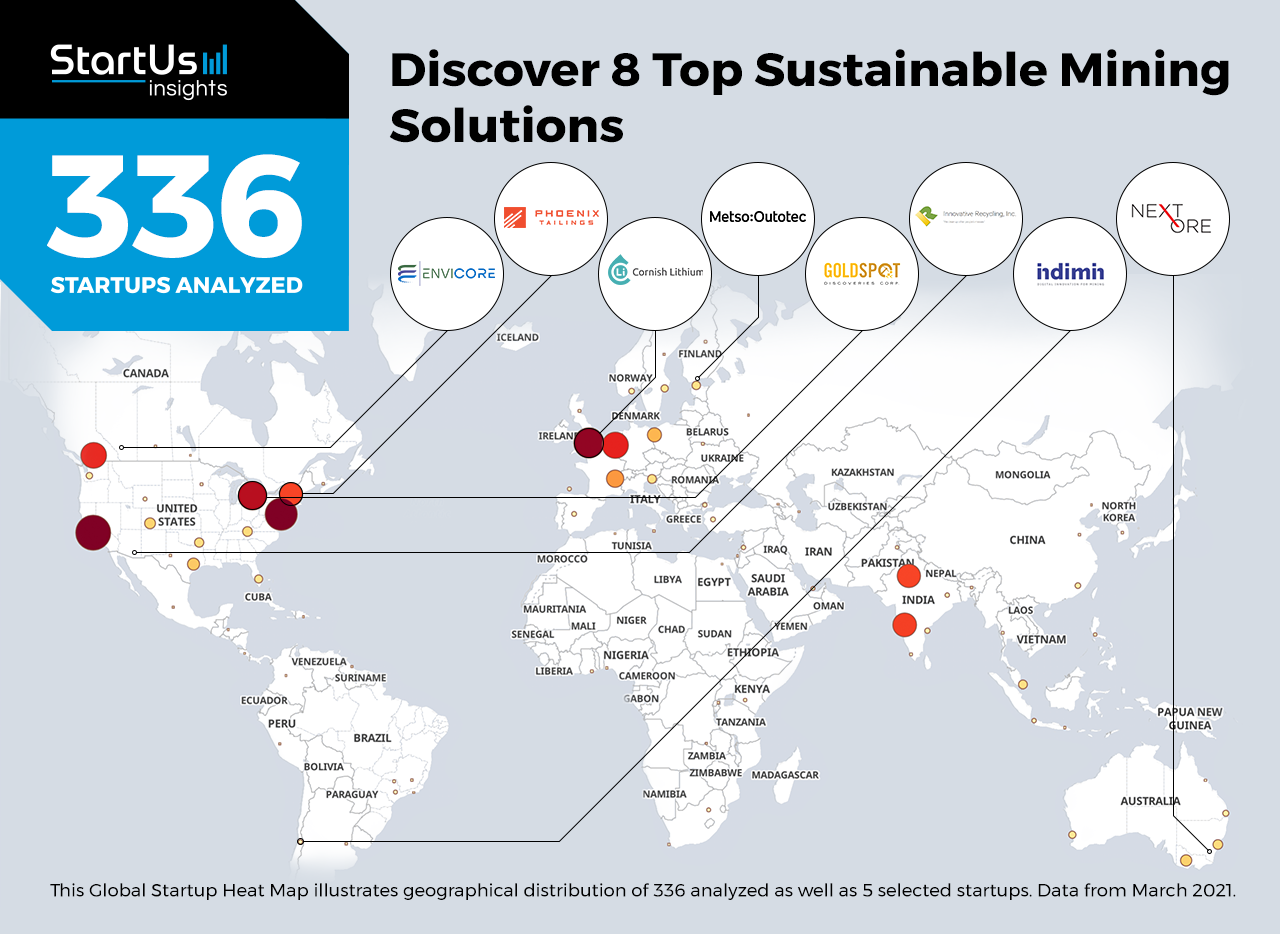

Global Startup Heat Map highlights 8 Top Sustainable Mining Startups out of 336

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 1.379.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 336 exemplary startups & scaleups we analyzed for this research. Further, it highlights 8 sustainable mining startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 8 startups & scaleups in this report. For insights on the other 328 sustainable mining solutions, get in touch.

NextOre offers Magnetic Resonance Sensing-based Ore Sorting

The mining industry generates significant waste but sorting this waste helps facilitate a circular economy. However, sorting mineral compositions at a later stage, for example grinding, increases the waste in terms of energy consumption. This is where mineral sensing technology enables effective sorting processes early in the processing stage of the ore and reduces wastage significantly. To this end, startups leverage multiple sensing technologies including radio-frequency and X-ray transmission to develop sorting technologies for mining operations.

Australian startup NextOre leverages magnetic resonance sensing in their ore sorting solution. The startup’s product is capable of operating at typical mining rates of as much as 5,000 tonnes per hour, per conveyor belt, with no material preparation requirement. The sensing results include accurate, whole-of-sample grade measurements. Moreover, the solution provides transparency for tracking downstream processing and allows operations to selectively reject and reduce waste material. This enables sustainability in the earlier stages of mineral processing.

Metso Outotec enables Sustainable Mining Plant Operations

Careful planning in plant design for mining operations enables significant cost reductions as well as environmental benefits. For instance, mining solutions include grinding technologies and processing equipment specific to the mineral compositions of every mine. This results in the reduction of material waste in the grinding process. Startups develop efficient grinding solutions to sustainably reduce material wastage in mining.

Finnish startup Metso Outotec creates solutions to accelerate sustainability in mining operations including energy-efficient plant designs and equipment. Among other plant equipment, the startup offers customizable grinding solutions. Vertmill, a vertical grinding technology, significantly reduces energy consumption and operating costs in comparison to traditional ball mills. This also enables regrinding applications with highly variable flows. Further, the startup’s product portfolio includes stackers, railcar dumpers, ash conditioners, slurry hoses, and mining crushing stations. Together, the solutions help maximize the utilization of minerals from deposits.

Cornish Lithium develops Lithium Extraction Technology

Traditional lithium extraction involves the use of seawater brine at high temperatures, consuming a significant amount of energy for heating. This energy-intensive process of extracting lithium from the solid rock is harmful in comparison to extracting lithium from geothermal waters. This is because the heating is powered by naturally-occurring geothermal energy. To generate eco-friendly ways to extract important raw materials, like lithium, startups develop advanced extraction technologies that are sustainable and energy-efficient.

UK startup Cornish Lithium develops advanced eco-friendly lithium extraction technology that is sustainable and eco-friendly. Direct lithium extraction (DLE) technology enables the startup to extract lithium from geothermal waters. Moreover, in collaboration with Geothermal Engineering Limited (GEL), the startup is setting up a pilot facility to demonstrate the extraction of lithium from the geothermal waters found in Cornwall, UK.

Phoenix Tailings provides Re-mining Technology

After separating the valuable fraction of mineral resource from the uneconomic fraction (gangue) of ore, tailings are left behind. Some tailings contain arsenic and lead in the form of dust which, in high enough concentrations, can cause serious health problems. Moreover, rainfall on tailings leads to rainwater leaching away, thus the materials contaminate groundwater in surrounding areas. In order to tackle such issues, startups develop solutions that reuse and recycle tailings ponds.

The US-based startup Phoenix Tailings develops proprietary re-mining technology to improve the sustainability of mining operations. The startup reprocesses tailings ponds by treating them as a new ore and extracts individual valuable primary metals in a holistic and sustainable manner. As a result, mining companies reduce the amount of toxic waste that potentially contaminates the environment. Further, the startup’s technology enables mining companies to increase their output and strengthen the economic viability of mines. This contributes to long-term sustainability in terms of zero carbon emissions of mining operations.

Indimin improves Mining Operation Efficiency

As the mining industry increasingly adopts automation, the application of analytics in automation processes drives sustainability in mining. Analytics uses image analytics for accurate ground ore estimation and route optimization for reducing energy use in autonomous mining vehicles. Analytics platforms allow mining operators to expand their remote mining operations while maintaining high levels of sustainability.

Chilean startup Indimin specializes in personalized, predictive operational improvements to prevent loss and capture process improvements. Their smart digital assistant provides comprehensive data for mining operation information to superintendents and performance improvements to mine operators. The platform uses predictive analytics to increase mine operation efficiency, even in remote environments.

Goldspot develops Core Imaging Technology for Mining Operations

One of the major challenges in the exploration of gold deposits for mining is the analysis of the core samples and estimation of ground ores. The utilization of AI, machine learning, and computer vision provides a better understanding of the available mineral deposits and the viability of mining operations in a given location. Imaging technologies also help geologists examine older core samples to find previously undiscovered or missed mineral deposits.

Canadian startup GoldSpot Discoveries provides the mining industry with a core imaging technology to extract mineral content information from core samples. The startup’s proprietary core imaging technology, called LithoLens, automatically examines core images using deep learning algorithms to extract geological information. Additionally, the platform autonomously extracts information from drill core images and video, outcrop photography, and within-borehole sensors. This data is later processed on the cloud using machine learning techniques to draw insights.

Innovative Recycling processes Mining Waste Streams

Mining waste is a significant ecological problem that comprises overburden, run-off-mine rock as well as discard, slurry, and tailings from extraction plants. The waste generated from mining is most often dumped in landfills, with very little being reprocessed. Startups create special processes that use mining waste to create useful byproducts. These solutions further reduce the overall ecological impact of mining operations.

US-based startup Innovative Recycling specializes in the development of mining waste processing systems. Their development process begins with analyzing and evaluating mining operations to identify potential waste streams that can be used to create useful byproducts. They then procure materials for chemical analysis to determine a more accurate value of the material obtained from the waste stream. The startup’s solutions find applications in cleaning abandoned sites and restoring the surrounding environment.

EnviCore develops Oil Sands Tailings Treatment Technology

The production process of bitumen extraction from oil sands results in the generation of large quantities of waste tailings. The water used in the extraction process cannot be released into the environment due to the high toxicity levels from chemical residue. For this reason, startups are developing alternative methods and chemicals to process oil sands and reduce the amount of toxic waste and overall cost of waste material handling.

Canadian startup EnviCore provides oil sand mine operators with tailings treatment technologies. The technology is based on the mixing of inexpensive commodity chemicals to create a flexible retrofit. This enables fast sediment fortification resulting in strong brick-like sediment that contains up to 80% weight in solids. The solids entrap residual wastewater organics and dissolved ionic impurities. In this way, EnviCore provides a significant amount of cost savings to mine operators. Further, the solutions reduce the impact on the environment by lowering greenhouse gasses (GHGs) from tailing streams.

Discover more Sustainable Mining startups

The 336 sustainable mining startups, such as the 8 examples highlighted in this report, focus on reducing the environmental impact of mining operations, as well as improving efficiency and reducing costs. While all of these technologies play a major role in advancing the mining industry, they only represent the tip of the iceberg. To explore more mining technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry Innovation Reports to save your time and improve strategic decision-making.