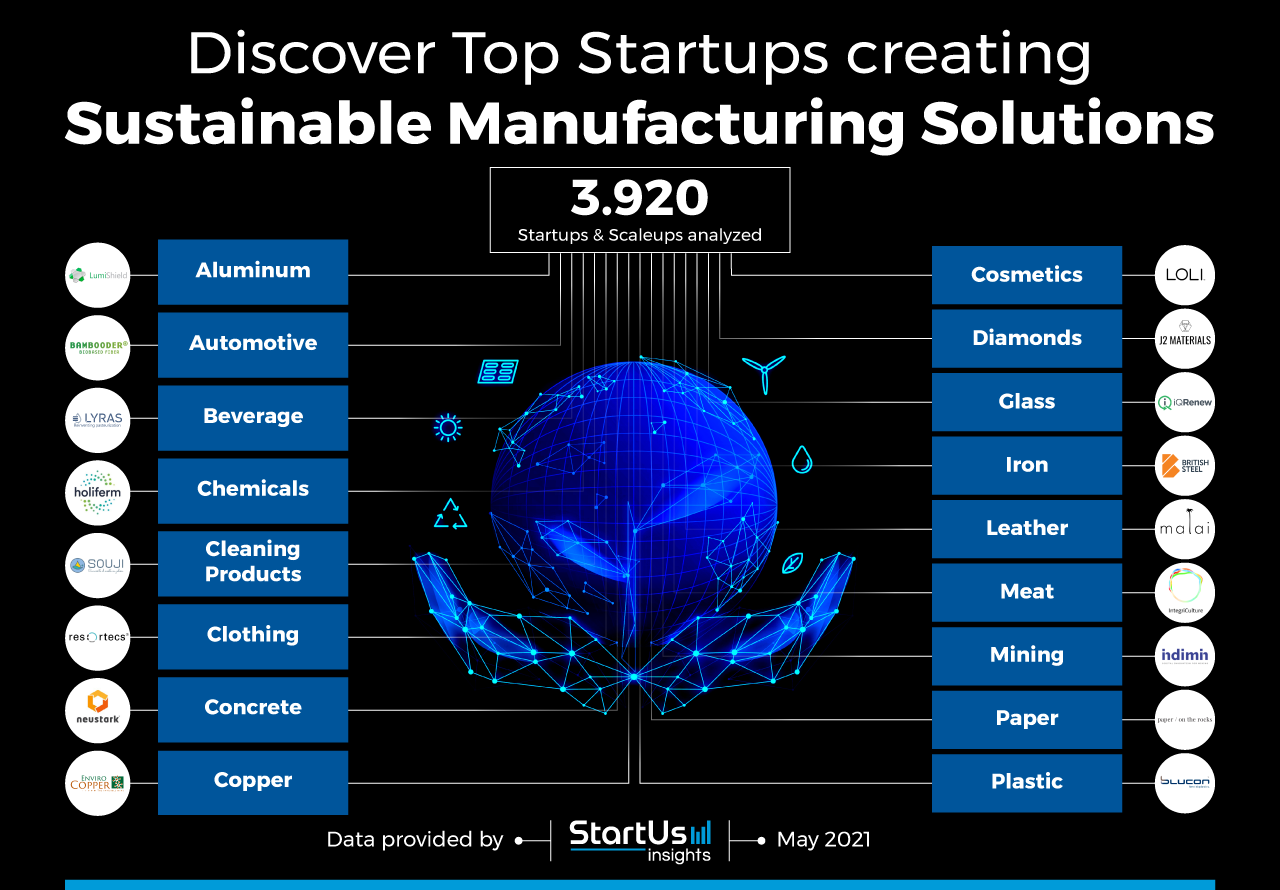

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights based on our analysis of 3.920 sustainable manufacturing startups & technologies. This time, you get to discover 17 sustainable manufacturing trends and hand-picked startups reducing the environmental impact of manufacturing.

Innovation Map highlights Global Sustainable Manufacturing Startups impacting 17 Industries

For this in-depth research on the top sustainable manufacturing startups, we analyzed a sample of 3.920 global startups and scaleups. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform quickly delivers an exhaustive overview of emerging technologies within a specific field as well as identifies relevant startups & scaleups early on.

In the Innovation Map below, you get an overview of the 17 industries adopting sustainable manufacturing processes that impact factories and manufacturing plants worldwide. This research gives you data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups developing environmentally friendly manufacturing solutions.

Explore Top Sustainable Manufacturing Startups

1. Aluminum

The durability of aluminum enables manufacturers to use it for different applications, from construction to aerospace. Even though uncontaminated aluminum is infinitely recyclable, different chemical and electrolytic reactions while processing generates a considerable carbon footprint. Startups devise unique methods to reduce greenhouse gas (GHG) emissions and promote sustainable manufacturing of aluminum-based products. Further, startups also reduce the aluminum lost to landfills; significantly impacting aluminum recyclers. Some examples of sustainable aluminum include:

- GHG Emission Reduction in Aluminum Smelting

- Aluminum Bottles for Packaging

- Recyclable Aluminum Fuel Cells

- Aluminum-based Bicycles

- Corrosion Resistance

LumiShield provides Aluminum-based Corrosion Resistance

US-based scaleup LumiShield is a spinoff from Carnegie Mellon and the National Energy Technology Laboratory. The company develops an aluminum-based replacement for phosphates, chromates, primers, and mechanical prep for metal surface coating, Lumidize, which is cost-effective and environmentally friendly. Lumidize uses proprietary aqueous plating chemistry that allows water-based deposition of aluminum and is used in automotive, aerospace, and more.

Explore our full analysis of top sustainable aluminum manufacturing startups.

2. Automotive

While vehicles with conventional combustion engines are still dominant, many automotive producers are turning to sustainable alternatives. To align with GHG reduction goals, manufacturers search for innovative electric traction options. Startups create environmentally-friendly motors, materials, and electric systems to accelerate a carbon-neutral future for mobility. For example, tires end up in landfills or illegal dumping grounds, which exacerbates the ecological situation. To counter this, startups create new feedstock-derived materials such as sustainable synthetic rubber or plant-based rubber to make tires. Some examples of sustainable automotive manufacturing include:

- Environmentally-friendly Motors

- Green Composites

- Eco-friendly Tires

- Electric Vehicle (EV) Charging Stations

- Sustainable Window Glass Tint

Bambooder develops Green Composites

Dutch startup Bambooder produces green composites for automotive, aerospace, marine, energy, and other industries. The startup develops a patented technology to convert natural unidirectional bamboo fibers into bio-based lightweighting prepregs. Utilizing the strength and solid performance of bamboo, the startup promotes eco-friendliness for exterior and interior automotive components.

Read more about top sustainable manufacturing startups impacting the automotive industry.

3. Beverages

Utilizing agricultural waste as raw ingredients presents a way for beverage companies to make their production sustainable. It reduces the environmental impact by diverting waste from landfills as well as reducing the need for land to grow the crops for ingredients. Startups focus on low-sugar options, plant-based alternatives, as well as artificial proteins to reduce the environmental impact of traditional beverage production. A few examples of sustainable beverage production include:

- Cold Pasteurization Technology

- Sustainable Distilling

- Plant-based Milk

- Soy Alcoholic Beverages

- Liquified CO2

Lyras develops Cold Pasteurization Technology

Danish startup Lyras develops cold pasteurization technology to minimize water and energy use in the process. The startup’s technology uses low-pressure germicidal lamps that produce disinfecting UV light. This reduces the need for water in the production of dairy as well as juices, soft drinks, and other beverages. The process also saves energy and lowers the carbon footprint by eliminating the need for energy-intensive heating.

Get to know 5 top sustainable production startups impacting beverage companies out of 308.

4. Chemicals

Manufacturing waste is a challenge for chemical companies as it requires time and money to get rid of. Current practices also generally utilize fossil-based raw materials to produce the chemicals. Moreover, through wastewater streams, these often end up in rivers where they hurt biodiversity. To address this, startups and scaleups are working on sustainable manufacturing solutions for the chemical industry. For example, solutions that channel waste into manufacturing new products enable both sustainable manufacturing and a circular economy. Some examples of sustainable manufacturing in chemical industries include:

- Green Hydrogen

- Sustainable Agrochemicals

- Biosurfactants

- Sustainable Colorants

- Cellulose from Waste

Holiferm produces Biosurfactants

British startup Holiferm produces biosurfactants from renewable feedstocks. The startup develops HoneySurf LF, a low-foaming biosurfactant using a yeast species found in honey and a natural fermentation process. It finds applications in hard surface cleaners, face creams, shampoos, and conditioners. Holiferm also offers a high-foaming biosurfactant, HoneySurf HF, by adding a chemical modification step after the fermentation process.

Meet the 5 top sustainable chemicals manufacturing startups out of 333.

5. Cleaning Products

Chemical detergents are toxic and harm human health and the environment when mixed into the ecosystem. To minimize the negative effect of conventional cleaning products, startups are looking for safer alternatives and develop solutions from natural ingredients. Further, to reduce the use of single-use plastic bottles and minimize damage to the environment, startups develop reusable and recyclable packaging solutions for cleaning products. Finally, emerging solutions eliminate the use of parabens, formaldehyde, phthalates, glycol solvents, artificial colors, or VOCs that harm both health and the environment.

- Non-Toxic Disinfecting Household Cleaners

- Zero-Waste Cleaning Products

- Cleaning Products using Recycled Vegetable Oil

- Sustainable Laundry Solutions

- Bio-based Fragrance Microcapsules

Souji recycles Vegetable Oil to create Cleaning Products

Spanish startup Souji offers cleaning soaps and detergents from recycled vegetable oil. The startup develops filters to convert used vegetable oil into a detergent without the use of caustic soda. Customers pour the oil through the filter and shake the bottle to get an environmentally-friendly cleaning product. The detergent is suitable for use in washing machines or hand-washing clothes, as well as for mopping floors and washing dishes.

Discover our analysis of 5 top sustainable manufacturing startups developing cleaning products.

6. Clothing

The unsustainable practices in fast fashion contribute to environmental pollution and huge CO2 emissions. Most people throw away the garment by the time the next season arrives, leading to preventable emissions. To produce sustainable garments suitable for recycling and reuse, fashion brands need information about circular materials and optimal designs. Today, only a small percent of garments are recycled. Most of them end up either in landfills or are burned. Technologies that allow the recovery of materials from discarded textiles enable resource reuse for the creation of new products. Take a look at 7 examples of sustainable clothing solutions:

- Circular Design Software

- Merchandise Management Platform

- Garment Disassembly Technology

- Textile Material Recovery

- Reversible Coloring Technology

- Clothes from Recycled Fibers

- Upcycled Fabrics

Resortecs offers Garment Disassembly Technology

Belgian startup Resortecs offers patented technology for automatic disassembly of apparel at an industrial scale. The startup’s solution combines the melting of stitching threads with industrial disassembling ovens to dismantle garments five times faster than traditional methods. This separates different clothing materials, enabling their reuse in their original form.

7. Concrete

Cement production causes some of the largest GHG emissions globally. To address this, there is a push for smart and sustainable construction materials, as well as alternative processes for cement manufacturing. Startups leverage nanotechnology to develop sustainable substitutes for cementitious materials. Startups are also working on concrete reinforcement solutions that utilize recycled steel. Construction companies are also looking for efficient manufacturing processes and low-carbon sources. For example, 3D printing allows manufacturers to shorten their supply chains and reduce material waste while facilitating sustainability. Check out 5 application areas for sustainable concrete manufacturing:

- Nanocement

- Steel Fiber for Concrete Reinforcement

- Geopolymers

- Robotic 3D Printing

- Atmospheric Carbon Capture

neustark enables Atmospheric Carbon Capture

Swiss startup neustark removes carbon dioxide (CO2) from the atmosphere and stores it in recycled concrete. It applies the principles of natural mineralization, accelerating it to capture carbon more efficiently. This also optimizes concrete usage to minimize cement usage in concrete manufacturing. The startup’s concrete meets all standard quality criteria of workability, compressive strength, modulus of elasticity, and durability.

Dive into our analysis of 5 top sustainable manufacturing startups impacting concrete producers.

8. Copper

Climate change and environmental degradation is causing many countries to increase their sustainability efforts, especially in the mining industry. Natural resource depletion is inevitable as many essential metals, including copper, zinc, iron, and gold, are continuously increasing in demand. Mining companies consider both the social and environmental impact of mining operations to adapt their operations in line with industry regulations. As a result, mining startups leverage data, advanced analytics, and renewable energy in their operations to improve their sustainability. Take a look at 5 such examples:

- Invisible Mines

- Zero-Harm Mining Operations

- Single-Layer Traces for Printed Electronics

- Sustainable Tailings Management

- Co-Disposal Methods

EnviroCopper develops Invisible Mines

Australian startup EnviroCopper develops invisible mines by leveraging in-situ recovery (ISR) for copper and gold mining. The startup dissolves the commodity in place and then extracts them using a system of injection and extraction bores or wells. ISR lowers the environmental impact of mineral extraction in comparison to open-cut and underground mining.

9. Cosmetics

Due to the growing waste generated by cosmetics and their packaging, tonnes of trash end up in landfills, incinerators, and oceans. To tackle this problem, and address consumers’ environmental concerns, cosmetics startups develop alternatives to chemical ingredients by replacing them with zero-waste ingredients. Many cosmetics companies also use petrochemical ingredients derived from non-renewable and economically volatile resources. Such ingredients are also harmful to the human skin in the long term. Startups respond by developing, In particular, plant-based packaging for daily-use products and organic cosmetics. Sustainable cosmetics cover, among others, the following 5 applications:

- Skin-Soothing Essence from Corals

- Zero-Waste & Organic Cosmetics

- Organic Red Palm

- Plant-based Packaging for Eco-Friendly Cosmetics

- Сoffee-based Additives for Cosmetics

LOLI develops Zero-Waste & Organic Cosmetics

US-based startup LOLI manufactures cosmetics containing zero-waste ingredients. Some of their most sold products include rose water, organic face serum, makeup remover, and moisturizer. Moreover, all their packaging is plastic-free and completely recyclable. Their products are also environmentally friendly, organic, and wild-harvested to avoid unnecessary waste during production.

Read more about 5 top sustainable cosmetics manufacturing startups out of 261.

10. Diamonds

The high environmental and social toll during mining and recovery, as well as transportation of natural diamonds, reduce the demand for the product. Although diamond manufacturing companies pledge to decrease CO2 emissions and mitigate water pollution from acid mine drainage, the rate of change remains slow. Therefore, startups develop solutions that enable diamond production in a laboratory. At the same time, diamonds mined with the involvement of child labor, human rights violations, and unsustainable practices find ways to enter the supply chain. To prevent this, startups develop blockchain solutions that enable traceability in the natural diamond industry. In addition, some other examples include:

- Diamonds via Chemical Vapor Deposition (CVD)

- Synthetic Diamond Solutions

- Sustainable Diamond Manufacturing

- Diamond Semiconductor Technology

- Ethical Diamond Sourcing

J2 Materials lowers Methane Emissions during Diamond Manufacturing

US-based startup J2 Materials advances the sustainability of diamond production. The startup’s proprietary process lowers methane emissions during the CVD process. To further increase the sustainability of synthetic diamonds, J2 Materials produces hydrogen, another essential CVD element, by splitting tap water on-site.

11. Glass

Operating glass manufacturing units takes up significant energy and processing costs. Glass manufacturers look to reduce their environmental impact, including air and water pollution, to increase the sustainability of the industry. Moreover, governments globally demand and legislate for zero-waste and circular economy solutions, driven by a rapid rise in consumer concerns. To this end, startups and scaleups develop glass products that comprise recycled glass or use low-energy methods for making glass. 5 such examples of sustainable glass production include:

- Sustainable Glass Products

- Recycled Glass

- Glass Sand

- Ultra-Lightweight Foamed Glass Aggregates (UL-FGA)

- Recycled Glass Products

iQ Renew manufactures Glass Sand

Australian startup iQ Renew manufactures recycled glass sand to support the construction and civil engineering industries. The smooth surface and angular shape characteristics of glass sand provide unique benefits over sand alternatives and also make it an ideal drainage medium. Further, the startup offers patented engineered silica that is a plant nutrient and is used in soil enhancement. This product is available in both granule form and liquid form.

Meet 5 top sustainable glass manufacturing startups out of 252.

12. Iron

The infrastructure costs of connecting ore mines to grid networks are significant. Moreover, mining for iron ore poses threats to air and water quality, as well as biodiversity and ecosystems. To sustainably mine iron ore, organizations employ processes, such as automation, to enable sustainable best practices that focus on the safety of mine workers and mitigate the impact on the environment. By improving the efficiency of manufacturing equipment and processes, metal manufacturers further lower energy consumption. Such standardization also decreases manufacturing time and reduces resource use and wastage. Discover a few examples of sustainable iron extraction and production:

- All-Electric Mining Fleets

- Tailings Safety Initiatives

- Sustainable Energy Usage

- Electrolyzer Technology

- Sustainable Manufacturing Standards

British Steel employs Sustainable Manufacturing Standards

British startup British Steel manufactures semi-finished products including sections, rails, and rolled billets by prioritizing the use of external recycled content in its manufacturing processes. Moreover, the company leverages the methodology from the international standard ISO 14021 to measure and assess the recycled content of steel products. Further, it is certified by the Environmental and Sustainability Standard BES 6001 related to Responsible Sourcing of Products. This ensures that the startup’s suppliers also form part of a sustainable supply chain.

13. Leather

The leather industry is a large contributor to GHG emissions and global waste generation. Current methods to meet the increasing demand for leather require raising more livestock, which further exacerbates the environmental challenges. Startups develop bio-based alternatives to create textiles that have similar or superior characteristics to livestock-based leather. Other emerging solutions mix the organic waste with other organic materials to create leather alternatives, expanding the applications of organic waste beyond agriculture. Explore 5 ways startups are enabling a sustainable leather economy:

- Gelatin Nanofiber Textiles

- Apple Cider-based Leather

- Vegan Leather

- Biocomposite Leather Alternatives

- Leather Tanning Extracts

Malai creates a Biocomposite Leather Alternative

Indian startup Malai uses agricultural waste generated by the coconut industry to create bio-based materials. Malai is a biocomposite leather alternative made from organic and sustainable bacterial cellulose, grown on coconut agricultural waste. It is highly durable, water-resistant, flexible, and feels similar to conventional leather. The use of bacteria and agricultural waste allows the production process to be low-cost.

Learn more about 5 top sustainable leather manufacturing startups out of 130.

14. Meat

Animal agriculture is currently the largest global contributor of CO2 and methane emissions. Moreover, by clearing forest land for animal agriculture, meat production is causing unprecedented damage to natural ecosystems. However, the meat industry is slowly moving towards a transition of lab-grown meat over traditional meat. This is helped by the increasing consumer acceptance of artificial meat and the overuse of antibiotics in animal farms. Further, startups are advancing cell culture to produce affordable and scalable platforms that create lab-grown consumer products.

- Crustacean Cell-based Seafood

- Cultured Meat Products

- Lab-Grown Beef

- Cultured Chicken

- Platforms for Cellular Agriculture

Integriculture manufactures Platforms for Cellular Agriculture

Japanese startup Integriculture develops a unified cell agriculture platform called Uni-CulNet. The platform creates a cell growth environment that imitates the conditions inside of an animal during growth. The imitated environment removes the requirement of adding external growth factors which are typically associated with the high cost of cell culture development.

15. Mining

The mining industry generates significant waste but sorting this waste helps facilitate a circular economy. Startups leverage multiple sensing technologies, including radio-frequency and X-ray transmission, to develop sorting technologies for mining operations. To further generate eco-friendly ways to extract important raw materials, like lithium, startups develop advanced extraction technologies that are sustainable and energy-efficient. After separating the valuable fraction of mineral resources, tailings are left behind. Some tailings contain arsenic and lead in the form of dust which, in high enough concentrations, cause serious health problems. Discover how startups & scaleups tackle this, as well as 7 other challenges facing the mining industry:

- Magnetic Resonance Sensing-based Ore Sorting

- Sustainable Mining Plant Operations

- Lithium Extraction Technology

- Re-mining Technology

- Improving Mining Operation Efficiency

- Core Imaging Technology

- Mining Waste Streams

- Oil Sands Tailings Treatment Technology

Indimin improves Mining Operation Efficiency

Chilean startup Indimin specializes in personalized, predictive operational improvements to prevent loss and capture process improvements. Their smart digital assistant provides comprehensive data for mining operation information to superintendents and performance improvements to mine operators. The platform uses predictive analytics to increase mine operation efficiency, even in remote environments.

16. Paper

A significant amount of non-biodegradable plastic waste is generated on a daily basis. Startups re-purpose waste into biodegradable tableware to close the loop on waste generation and enable effective utilization of resources. At the same time, leveraging alternative materials for making paper and paper-based packaging products decreases the pressure on natural resources, already depleting at an alarming rate. Compared to traditional pulp-based paper, the processing of plant-based and waste-based paper is more eco-friendly. Startups develop cost-effective methods to manufacture eco-friendly and sustainable paper and paper-based packaging. Some examples of sustainable paper manufacturing include:

- Sustainable Paper Packaging

- Biodegradable Paper Plates

- Tree-Free Paper

- Recycled Paper-based Packaging

- Hemp Paper

Paper on the Rocks manufactures Tree-Free Paper

Dutch startup Paper on the Rocks offers tree-free paper to be used in books and notepads. The startup uses recycled plant waste that includes stems and leaves to manufacture tree-free paper. This process directly results in a smaller carbon footprint in comparison to pulp-based paper. Further, the startup enables the effective utilization of agricultural land by producing both food and paper from the same area of land.

Read more about the 5 top sustainable paper manufacturing startups impacting the industry.

17. Plastic

Plastic bag production is one of the biggest contributors to plastic pollution. Moreover, because of the complexity and high cost associated with recycling, most plastic bags are left to decompose in landfills – which takes a few hundred years to decompose. Highly critical volumes of plastic waste also end up in the ocean, endangering marine ecosystems globally. Additionally, more and more microplastic are found in fish and accordingly, make their way into human bodies via seafood. To tackle this situation, businesses and research institutions develop alternative solutions to plastics including plant-based plastics that are biodegradable. Discover 5 ways startups are trying to create shorter life cycles for plastics:

- Plant-based Single-Use Plastics

- Bioplastics from Food Waste

- Bioprocess Engineering

- Enhancing Bioplastics’ Properties

- Biological Alternatives to Plastic Bags

BluCon Biotech works on Bioprocess Engineering

German startup BluCon Biotech develops L-lactic production technology that enables the consolidated bioprocessing (CBP) of lignocellulosic feedstock using thermophilic bacteria. The startup’s technology also allows for the use of various agricultural and industrial materials such as straw, cotton, and beet pulp. BluCon Biotech’s approach to bioprocessing facilitates the shift from petroleum-based to biodegradable and sustainable plastics.

Get to know 5 top sustainable plastic manufacturing startups impacting companies out of 332.

Discover the Latest Sustainable Manufacturing Startups

Every day, new startups and technologies emerge that improve the sustainability of manufacturing. These solutions span a range of industries, and emerging companies take advantage of organic and sustainable materials and processes, as well as data, AI, and IoT to implement sustainable practices. For example, French startup Dataswati offers PowerOP, an industrial process optimization engine for the food and beverage industry. With the help of digital twins, the startup enables manufacturers to visualize their production lines, identify anomalies, and improve sustainability. Moreover, the startup’s solution is customizable for all kinds of businesses. It takes into account user validations and feedback, as well as accumulates relevant knowledge.