Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into heavy industries. This time, you get to discover five hand-picked factory management solutions for heavy industries.

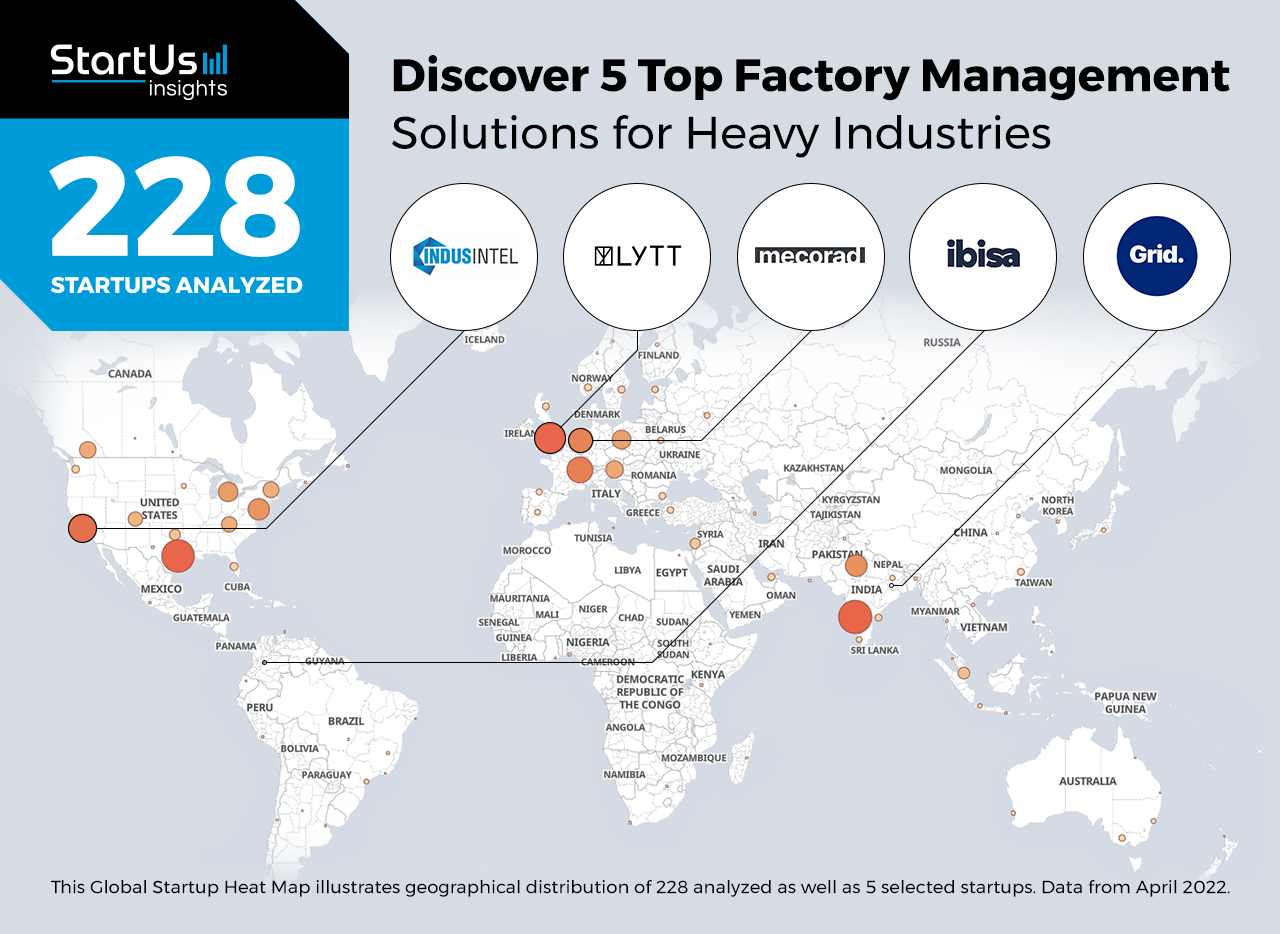

Out of 228, the Global Startup Heat Map highlights 5 Top Factory Management Solutions for Heavy Industries

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 228 exemplary startups & scaleups we analyzed for this research. Further, it highlights five heavy industry startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these five startups & scaleups in this report. For insights on the other 223 factory management solutions for heavy industries, get in touch with us.

LYTT improves Asset Visibility

Founding Year: 2019

Location: London, UK

Innovative with LYTT for Operational Decision-making

UK-based startup LYTT develops a data analytics platform that converts large volumes of sensor data into manageable and actionable insights. The startup’s solution for oil and gas production units uses fiber optics and time-series data for analyzing well and reservoir performance. The software provides real-time insights that allow operators to improve asset visibility and enhance operational decision-making. This increases production, improves reservoir management, and enables early risk identification.

IBISA offers Operational Process Visualization

Founding Year: 2016

Location: Bogota, Columbia

Use this solution for Factory Performance Optimization

Columbian startup IBISA develops an Industry 4.0 platform for operational process visualization. The startup’s solution creates a digital twin of the factory. It visualizes information regarding energy consumption, inventory visualization, and production order tracking. The solution also records production batch data and identifies process deviations, delays, and other abnormal activities. This improves the quality of analysis for making investment decisions, production plans, and maintenance schedules.

IndusIntel offers Machine Condition Monitoring

Founding Year: 2018

Location: San Jose, US

Innovate with IndusIntel for Machine Performance Analytics

US-based startup IndusIntel provides a real-time dashboard for production data and machine status. Mate, the startup’s system, collects data from operators and updates the machine status and displays it on a dashboard. The solution also allows quality inspectors to input the quality of the jobs produced by a specific machine. It digitizes factory management, thereby avoiding paperwork, saving time, and improving the accuracy of operations and quality tracking.

mecorad enables Digital Steel Production

Founding Year: 2018

Location: Köln, Germany

Use this solution for In-line Optimization

German startup mecorad develops measurement tools for the in-line optimization of digital steel production. The startup’s hardware solution measures geometries in the harsh conditions of metal forming industries. Mecorad’s industrial internet of things (IIoT) solution enables accurate measurements of any process step in real-time. This generates vital information for process optimization, enabling operators to realize a higher quality of products and reduce loss in production.

Grid provides Production Process Visualization

Founding Year: 2017

Location: Ranchi, India

Partner for Productivity Tracking

Indian startup Grid provides an integrated no-code data and operations management platform. The startup’s platform combines information generated by people, processes, and machines, and uses it to improve the collaboration between frontline workers and enable real-time decision-making for management. The startup creates tailored dashboards for each client to provide real-time insights from shop floor activities on production progress. The startup’s solution for mining operations manages the planning, scheduling, and optimization decisions of materials from pit to port. The solution in this way maximizes production and profits.

Discover more industrial Startups

Startups such as the examples highlighted in this report focus on automated inspection, lean manufacturing, and quality management. While all of these technologies play a major role, they only represent the tip of the iceberg. To explore industrial technologies in more detail, simply let us look into your areas of interest. For a more general overview, download our free Industrial Workplace Innovation Report to save your time and improve strategic decision-making.