Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into industry 4.0. This time, you get to discover five hand-picked factory management startups.

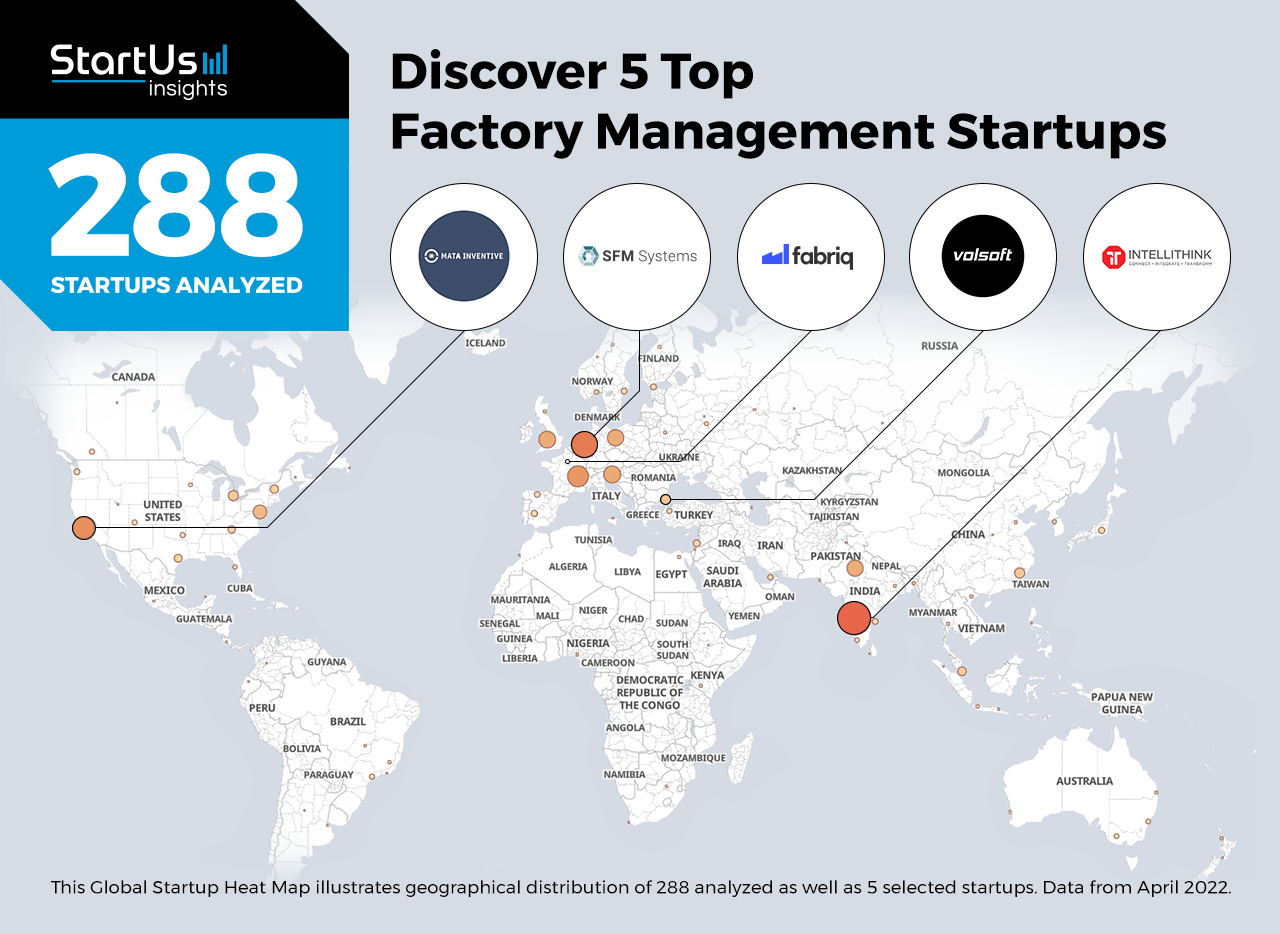

Out of 288, the Global Startup Heat Map highlights 5 Top Factory Management Startups

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 288 exemplary startups & scaleups we analyzed for this research. Further, it highlights five factory management startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these five startups & scaleups in this report. For insights on the other 283 factory management solutions, get in touch with us.

SFM Systems facilitates Shop Floor Optimization

Founding Year: 2018

Location: Darmstadt, Germany

Use this solution for Digital Shop Floor Management

German startup SFM Systems develops a digital shop floor management solution. It combines the industrial internet of things (IIoT) and AI to calculate and aggregate the key performance indicators (KPIs) for factory management. The built-in analysis tools also detect product and process deviations for shop floor optimization. This allows quick planning of remedial and improvement measures, thereby increasing production efficiency and reducing downtimes.

MATA Inventive simplifies Machine Monitoring

Founding Year: 2018

Location: Los Angeles, US

Innovate with Mata for Asset Utilization Optimization

US-based startup MATA Inventive uses firmware-embedded IoT monitoring devices to track the performance of machines on the shop floor. The startup’s platform, ArbIt, collects and analyzes this sensor data, including temperature, pressure, proximity, and vibration. It is compatible with any machine, sensor, or software and enables real-time data acquisition. ArbIt also provides actionable insights into production operations to eliminate bottlenecks due to personnel, equipment, parts, and processes.

Volsoft tracks Overall Equipment Effectiveness (OEE)

Founding Year: 2016

Location: Tekirdağ, Turkey

Use this solution for Asset Monitoring

Turkish startup Volsoft offers a production tracking and management system that monitors, manages, and avoids production losses. The startup’s OEE suite continuously collects machine data from programmable logic controllers (PLCs) and automation systems. It then monitors asset uptime, downtime, and utilization as well as detects anomalies to calculate the OEE. The suite also sets up alerts and recommends actions to improve the OEE of the factory.

Intellithink enables Predictive Maintenance

Founding Year: 2017

Location: Chennai, India

Partner with Intellithink for Equipment Condition Monitoring

Indian startup Intellithink provides an IIoT platform that processes data from connected machines on the factory floor. It uses deep learning for vibration- and motor current signature analysis (MCSA)-based condition monitoring. The current signature analysis provides insights into machine fault conditions and the extent of the faults, enabling predictive maintenance. Intellithink’s algorithms estimate the remaining useful life (RUL) of factory assets, which enables operators to reduce potential production downtimes and improve maintenance planning.

Fabriq facilitates Collaborative Problem Solving

Founding Year: 2019

Location: Paris, France

Reach out for Workshop Management

French startup Fabriq develops a workshop management system to improve the efficiency of collaboration in industrial setups. The startup’s tool is accessible to all members of an organization, from the shop floor to the boardroom. This improves inter-team collaborations and facilitates efficient monitoring of continuous improvement projects. Moreover, Fabriq’s solution identifies recurring issues on the line and detects performance gaps. These features allow engineers to avoid being physically present at the production line and yet collaborate more efficiently with line operators to resolve issues, saving time.

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on lean management, continuous monitoring, machine data acquisition, and process monitoring. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore industrial technologies in more detail, simply let us look into your areas of interest. For a more general overview, download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.