Despite challenges like high production costs, infrastructure limitations, and energy efficiency, the hydrogen generation market is set to grow at a compound annual growth rate (CAGR) of 10.3% from 2025 to 2028. According to recent data, the global hydrogen production is 75 million tonnes per year as pure hydrogen and 45 million tonnes as part of mixed gases.

This research-driven report explores the latest hydrogen trends in 2025, highlighting the growth of green hydrogen, fuel cell technologies, and more. You will also discover the key factors fueling these trends, recent market data, and 20 promising startups leading the innovations.

What are the Top 10 Hydrogen Trends in 2025?

- Green Hydrogen Expansion

- Fuel Cells

- Hydrogen Storage Innovations

- Artificial Intelligence (AI) in Hydrogen Operations

- Advanced Electrolysis

- Carbon Capture, Utilization, and Storage (CCUS) Integration

- Hydrogen Distribution Innovations

- Remote Hydrogen Production & Microgrids

- Blue Hydrogen

- X-to-Hydrogen-to-X

Methodology: How We Created this Report on Hydrogen Trends

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 5M+ global startups, 20K technologies & trends, plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative hydrogen trends.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the hydrogen innovation ecosystem while highlighting startups driving technological advancements in the industry.

Innovation Map outlines the Top 10 Hydrogen Trends & 20 Promising Startups

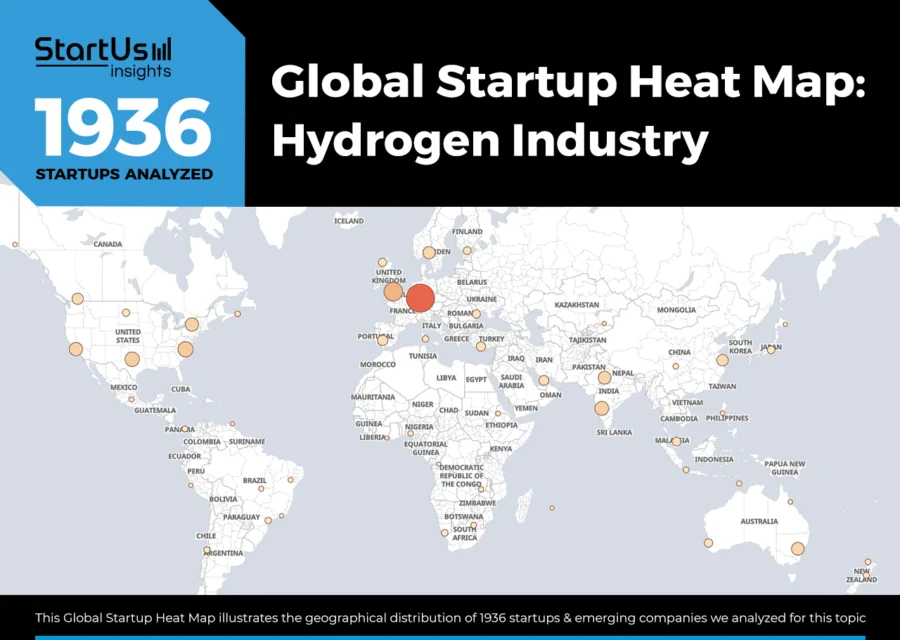

For this in-depth research on the Top Hydrogen Trends & Startups, we analyzed a sample of 1936 global startups & scaleups. The Hydrogen Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the hydrogen industry trends & startups that impact your company.

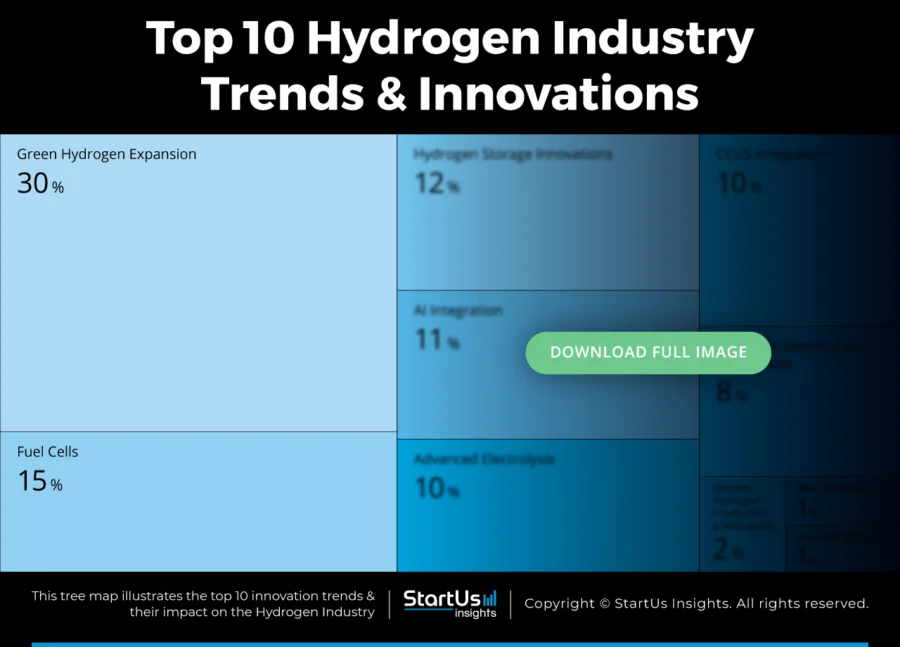

Tree Map reveals the Impact of the Top 10 Hydrogen Trends

The Hydrogen Industry Treemap highlights the influence of emerging trends such as green hydrogen growth, blue hydrogen, CCUS, hydrogen storage advances, and distribution innovations. Additionally, it reveals the relative significance of specific hydrogen trends and technologies shaping the industry.

Global Startup Heat Map covers 1936 Hydrogen Technology Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 1936 exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in the US and the UK, followed by India and Germany. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Hydrogen Trends & Innovations?

Top 10 Emerging Hydrogen Industry Trends & Innovations [2025 and Beyond]

1. Green Hydrogen Expansion

According to a report by the IEA, less than 1% of the hydrogen production process is low-emission. This led to the requirement for green hydrogen. Additionally, the aim to reduce fossil fuel dependency and decarbonization goals encourages investors worldwide to support green hydrogen expansion.

The expansion is visible in every stage, starting from production infrastructure to storage and distribution, and applications. Companies like ITM Power from the UK, Siemens Energy from Germany, and Nel ASA from Norway are working on scalable technologies for producing green hydrogen.

In 2024, companies like Siemens Energy and Air Liquide came together to invest in major green hydrogen production portfolios.

According to the Indian Union Budget 2025, the Indian government allocated INR 600 crore to green hydrogen – a 100% increase from last year.

A recent study by McKinsey also suggests there will be an expansion in the requirement for renewable energy to produce sufficient green hydrogen by 2050. Several countries, like China, India, Japan, and South Korea, have multiple green hydrogen projects. Additionally, researchers are working on using renewable sources, including algae, to increase green hydrogen production.

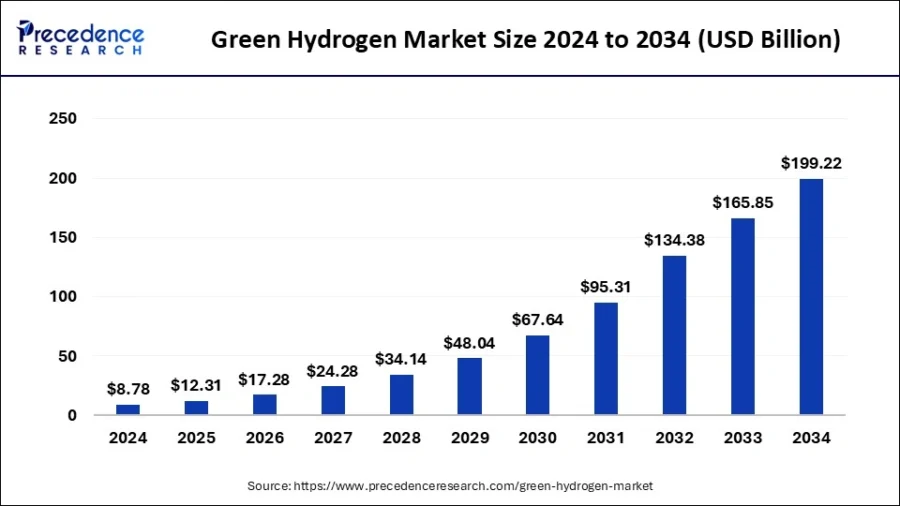

Currently, the green hydrogen market is worth USD 8.78 billion and is set to reach USD 199.22 billion by 2034, growing at a CAGR of 41.46%.

Source: Precedence Research

Stargate Hydrogen makes Alkaline Electrolyzers

Estonian startup Stargate Hydrogen builds containerized alkaline electrolyzers – its gateway series – for green hydrogen production. The company uses alkaline technology and uses a 40-foot container to optimize electricity consumption during hydrogen production. It is then pressurized to 30 bars in the output. The electrolyzer are suitable for chemical feedstock, process heat, blending, transport fuel, and energy storage.

The process does not use catalyst metals and is commercially sustainable. The electrolyzers are compatible with renewable energy, modular, and efficient while providing a cost-effective method for decarbonizing industries like steelmaking, fertilizers, and chemicals.

Latent Drive offers Seawater-to-Hydrogen Electrolyzer Stack

UK-based startup Latent Drive develops SeaStack, a direct seawater-to-hydrogen electrolyzer stack. Ideal for offshore establishment, it captures more wing energy than conventional electrolyzers by using a proprietary 2-stage water-split technology without desalination.

SeaStack produces hydrogen at the source and is fit for the fluctuating load. Latent Drive also provides platinum group metal-free catalyzed electrodes for electrolyzers.

Catalyzed electrodes combine the properties of electrodes and catalysts, and consist of activated stainless steel. The catalyzed electrodes make the mass production of green hydrogen feasible.

2. Fuel Cells

The demand for hydrogen fuel cells is rising as they provide a clean and efficient alternative to traditional fuel for decarbonization. Industries like transportation, industrial processing, petroleum refinery, and steel use hydrogen as a fuel source.

Researchers are working on nitrogen-doped catalyst technology to improve hydrogen fuel cell commercialization. They are also developing alloys that will act as catalysts for the fuel cell reaction. One of the innovations in this sector includes magnesium-platinum alloy nanoparticles. Further, research into palladium nanosheets for catalysts leads to more efficient hydrogen production.

In 2024, BMW launched a global pilot program for its hydrogen-powered iX5 SUV. It featured a 401-horsepower fuel cell system and a range of up to 500 kilometers. Plug Power, SFC Energy and MHI are other companies working on fuel cell technologies.

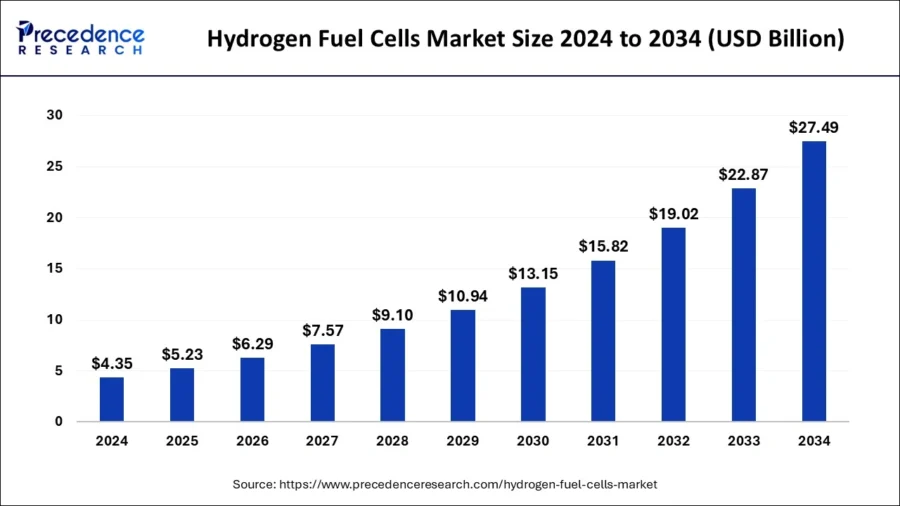

The hydrogen fuel cell market is estimated to grow at a CAGR of 20.24% from 2025 to 2034 and reach USD 27.49 billion.

Source: Precedence Research

Hydroplane builds a Fuel Cell Power Plant

US-based startup Hydroplane provides a modular hydrogen fuel cell power plant for general aviation, urban mobility, and vertical lift platforms. It is suitable as a single-engine aircraft retrofit.

Moreover, the fuel cell design addresses the proton exchange membrane (PEM) thermal management, durability, and cost of aircraft operations.

Hydroplane produces hydrogen using solar energy and water. Leveraging the company’s solution to switch to hydrogen-powered air travel thus reduces the CO2 footprint of operations.

Hydrovert Energy manufactures Hydrogen Fuel Cell Powertrains

Indian startup Hydrovert Energy provides hydrogen-powered powertrains and stationary generators for mobility applications like long driving range and quick refueling without diminishing payload quality. The zero-emission stationary generators replace the diesel generators and provide longer power backup.

3. Hydrogen Storage Innovations

Hydrogen storage solutions find applications in stationary power, portable power, and transportation. Hence it’s essential to research and develop hydrogen storage methods for maintaining profitable energy-per-volume ratios for hydrogen.

Research for explosion-free, self-venting (TPRD-less) Type IV storage is accelerating as safe transportation of hydrogen is becoming critical. Further, materials like multibinding sites united in covalent-organic frameworks (MSUCOM) and high entropy alloys allow storage and transportation of hydrogen at room temperature.

Researchers are additionally employing density function theory (DFT) simulations to test the efficiency of light-metal functionalized boron monolayers for hydrogen storage.

Underground storage of hydrogen is also gaining momentum with the UK, USA, Germany, Austria, and Sweden developing innovative solutions. In 2024, Uniper started a hydrogen storage pilot program at a salt cavern in Germany. Similarly, Sweden also established a lined hard rock cavern for hydrogen storage.

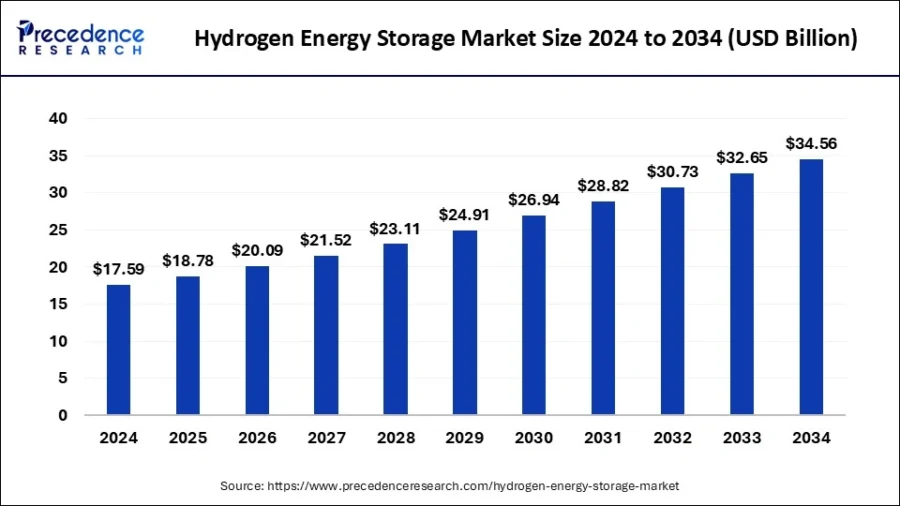

The hydrogen energy storage market will reach USD 18.78 billion in 2025 and grow at a CAGR of 7.01% from 2025 to 2034.

Source: Precedence Research

H2MOF enables Solid-State Hydrogen Storage

US-based startup H2MOF offers a solid-state hydrogen storage solution at low pressure and ambient temperature.

The startup utilizes artificial molecular machinery and reticular chemistry to develop solid-state nanomaterials with high hydrogen absorption capacity. It ensures safe hydrogen storage at low pressure and higher hydrogen charge and discharge rates.

The storage system addresses the cost and inefficiencies of the current methods of hydrogen compression and is suitable for long-term hydrogen storage and long-haul hydrogen transportation. It also allows hydrogen to be used as a fuel for light-duty vehicles, heavy-duty vehicles, and ships.

Hydrogen Space offers Metal Hydride Hydrogen Storage Systems

German startup Hydrogen Space builds metal hydride hydrogen storage systems for the space and aviation industries. The lightweight and compact storage systems allow more volume of hydrogen storage.

The startup uses its proprietary advanced metal hydride storage solution (AMH2SS) to increase hydrogen storage density. It also employs lightweight materials, like carbon nanotubes, titanium, and magnesium, for its construction. This enables more payload capacity and lowers operational and transportation costs. This way, it ensures safe hydrogen storage in extreme conditions of space.

4. AI in Hydrogen Operations

Artificial intelligence plays a crucial role in the hydrogen economy by optimizing production, storage, distribution, and safety. It also mitigates the challenges of hydrogen-enabled integrated energy systems.

Further, AI supports the research and development of novel materials with optimized properties that improve the efficiency of the hydrogen production process.

Siemens is using generative AI to develop the tools that design and automate hydrogen plants. Further, the European Marine Energy Centre is using an artificial intelligence platform – HyAI – for hydrogen storage and generation, created as a part of the HyAI 2.0 project.

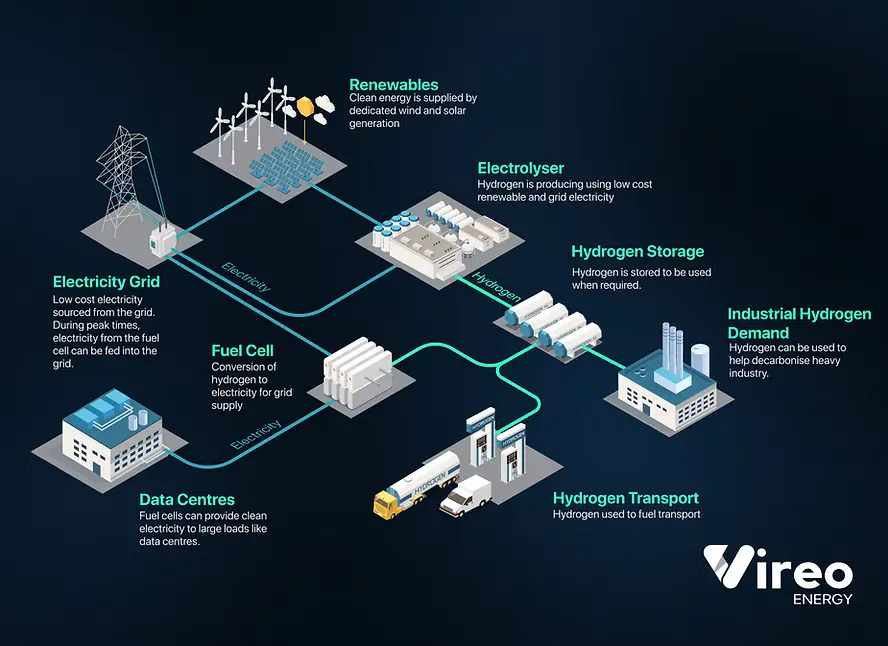

Vireo Energy offers a Hydrogen Production Optimization Platform

Australian startup Vireo Energy provides a real-time supervisory control platform for green hydrogen production control and analytics.

The platform simplifies the initial setup process of the green hydrogen production facility by automating operations, reducing costs, managing off-take, and slowing down membrane degradation.

The platform also combines digital twin and AI-driven forecasting. Vireo Energy uses live facility data to decide efficient electrolyzer operations and monitor the facility’s emissions and profitability.

Hyggle develops a Hydrogen Infrastructure Management Platform

French startup Hyggle builds an AI-powered digital platform for the economic and operational management of hydrogen energy infrastructure. It also optimizes green hydrogen production, storage, transportation, and distribution.

The platform connects hydrogen infrastructures, hydrogen markets, and any existing digital environment like enterprise resource planning (ERP) and SCADA. It also features a protected data hosting cloud infrastructure to offer a secure environment for data sharing.

Further, the platform leverages AI and data science to analyze technological, economic, and environmental dimensions and optimize hydrogen operations. The SCADA-connected real-time dashboard enables predictive analytics, equipment monitoring, and automated KPI tracking. The platform also sources and balances the electricity mix to assist in advanced planning and scheduling (APS) for transportation and distribution.

5. Advanced Electrolysis

Electrolysis is one of the cleaner methods of producing hydrogen. Using sustainable sources of electricity further makes it a process with zero greenhouse gas emissions. Methods like alkaline electrolysis systems and renewable energy grid-integrated water electrolysis systems are also gaining popularity.

Further, researchers are working on high entropy alloys to replace platinum as the catalyst in the electrolysis process. A team of scientists recently developed an ultra-efficient electrolyser that produces green hydrogen using renewable energy.

Water purification for hydrogen production consumes a significant amount of energy. Advances in seawater electrolysis enable the use of less clarified water for hydrogen production.

The dedicated electrolysis market for hydrogen production is set to reach a capacity of 230-520 GW by 2030, compared to 1.4 GW at the end of 2022.

Marine Dolphin designs an Anion Exchange Membrane (AEM) Electrolyzer

US-based startup Marine Dolphin develops an anion exchange membrane electrolyzer technology that mitigates the desalination step before converting seawater into hydrogen energy.

Instead of bipolar plates, the startup uses mass-produced materials for designing a channel for gases and complex fluids. The anode in the electrolyzer is highly active, corrosion-resistant, fully selective, and ensures an oxygen-creating reaction in seawater. The cathode improves the electrochemical stability of the hydrogen-producing reaction.

Further, the startup uses a single-step electrodeposition reaction and more cost-effective materials to create a catalyst for industrial-scale hydrogen production.

Avoxt advances the Membrane-Less Electrolyzer Technology

Dutch startup Avoxt creates a membrane-less electrolyzer for hydrogen production that reduces the levelised cost of hydrogen (LCOH). It quickly reaches its highest load capacity and addresses the fluctuation challenges of the green energy input. The membrane-less electrolyzer uses alkaline technology to eliminate the dependency on expensive catalysts like platinum and iridium.

Due to the absence of a membrane, it utilizes less energy than conventional electrolyzers for producing hydrogen. The absence of a membrane further reduces the maintenance costs, as replacing a damaged membrane is costly.

6. CCUS Integration

Integrating CCUS into hydrogen production enables cleaner ways of hydrogen production, which is essential as most hydrogen production methods depend on non-renewable sources. This enables the production of blue hydrogen while mitigating CO2 emissions. CCUS-integrated hydrogen production process also contributes to industrial decarbonization.

Chinese energy company Sinopec has developed a megatron-scale CCS project, which contributed to managing carbon content in the hydrogen production. Similarly, Air Liquide is investing in carbon capture methods for the US hydrogen energy market.

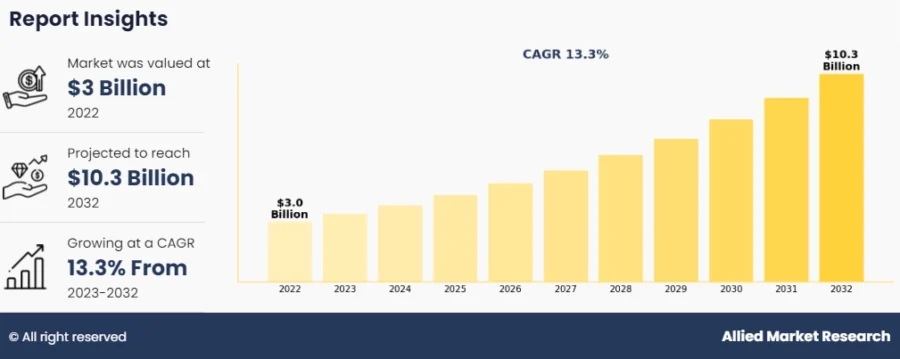

The global CCUS market is set to grow at a CAGR of 13.1% from 2023 to 2032, reaching USD 10.3 billion by 2032. This also indicates the growth of CCUS methods adoption in the hydrogen economy.

Source: Allied Market Research

Hydrogen Canada enables CO2-free Hydrogen Generation

Canadian startup Hydrogen Canada produces CO2-free hydrogen and ammonia for commercial and industrial applications like refining petroleum, treating metals, fertilizer, and chemicals. The startup uses an autothermal reforming (ATR) process to produce hydrogen and carbon monoxide by partially oxidizing hydrocarbon feed.

The CO2 produced is stored underground using a carbon capture plant. The startup converts hydrogen to ammonia for efficient transportation. This ammonia is directly usable for coal co-firing and bunkering. Once dehydrogenated, it is further suitable for hydrogen use.

Wild Hydrogen produces Carbon-Negative Hydrogen from Biogenic Material

UK-based startup Wild Hydrogen develops a rising pressure reformer (RiPR) technology to produce carbon-negative hydrogen from feedstocks. It includes industrial waste, domestic waste, and grown fuel crops. The technology addresses the challenges of large-scale biogenic hydrogen production.

RiPR liberates the hydrogen from biogenic materials to produce synthesis gas for the downstream process. The startup also employs additional CO2-separating and capturing systems to produce carbon-negative hydrogen and biomethane.

RiPR converts the wet biogenic material into hydrogen through supercritical water reformation (SCWR). The characteristics of supercritical water enable a single-phased reaction environment, which promotes fast and homogeneous reactions. The use of reformation methods eliminates electrolysis and, as a result, uses less electricity.

The tunable process further produces different CO2 removal (CDR) products. The technology is suitable for industries like energy and transportation.

7. Hydrogen Distribution Innovations

Advances in hydrogen distribution methods are essential as hydrogen has low volumetric energy density, and how it is transported to the point of use further impacts its quality. Additionally, cheaper and accessible hydrogen distribution methods enable wider adoption and application of hydrogen as a clean fuel in different sectors.

Businesses use vacuum-insulated cryo tanks for liquid hydrogen distribution. Chemical hydrogen carriers are also popular methods for hydrogen transportation in a stable environment. Advanced pipelines assist in transporting hydrogen with innovations including fiber-reinforced polymers. Further, countries are expanding hydrogen pipelines to ensure efficient distribution.

The hydrogen pipeline market is expanding at a CAGR of 16.20% from 2025 to 2032.

United Fiber Sensing offers Hydrogen Leak Detection Systems

Dutch startup United Fiber Sensing ensures the safe transportation of hydrogen with a hydrogen leak detection system. It features explosion-safe fiber optics and fiber optics sensors for electrolyzers, hydrogen pipelines, storage tanks, laboratories, and more.

The detection system’s optical sensing interrogator and graphical user interface (GUI) allow companies to manage the interrogation unit and data gathering. The sensor detects the least amount of molecular hydrogen leakage using light, which makes operations safer than using electricity to detect leaks.

arculus makes Hydrogen Gas Distribution Pipeline Retrofit Products

US-based startup arculus provides retrofits for hydrogen gas transmission pipelines for transporting blended and pure gas safely and cost-effectively.

The hydrogen out-pumping wrap prevents the pipeline from becoming brittle over time. It consists of an electrochemical configuration that utilizes a proton-conductor and a counter electrode to pump hydrogen through the steel pipe. The configuration keeps the mechanical and structural properties of the pipeline intact, and the selection of electrolyte makes the method ideal for wet and dry conditions.

The composite hydrogen barrier coating is a multi-layer coating that protects hard steel from hydrogen embrittlement and stress-induced cracking. Its metal interlayer structure ensures physical and mechanical compatibility with the pipeline metal.

The barrier enables the formation of extended space-charge zones at the oxide/metal interfaces, which repel hydrogen. Its composite structure further features self-healing and resists micro-cracking to maintain the barrier performance even with significant mechanical damage.

8. Remote Hydrogen Production & Microgrids

Hydrogen-based microgrids work independently of a centralized grid to make renewable electricity available at remote places. Additionally, hydrogen-based microgrids act as an efficient method of hydrogen storage. Urban hydrogen microgrids further ensure stable power availability during peak hours and reduce stress on the centralized grid.

NTPC India designed a solar hydrogen-based microgrid system that operates independently and supplies 200kW of power throughout the year. Researchers are also working on innovations in remote hydrogen production to fulfill the growing demand for hydrogen in the European transport sector.

Scientists are also developing energy management systems (EMS) for managing hydrogen-fueled microgrids. Green Hydrogen Systems is developing a modular, large-scale, high-pressure hydrogen electrolyzer called HyProvide X-1200 that enables remote control of operations in the hydrogen economy.

Further, Worley, ABB, and IBM came together to build the concept of Green Hydrogen in a Box. It allows companies to quickly sett up hydrogen infrastructures remotely and meet industrial energy requirements.

HYDGEN manufactures an On-Site AEM Electrolyzer

Singaporean company HYDGEN produces decentralized green hydrogen using an AEM electrolyzer and proprietary developments in catalyst and coating designs, membrane technology, and bipolar plate engineering.

The electrolyzer combines advanced catalyst materials and optimized membranes for energy-efficient hydrogen production. The electrolyzer is compatible with renewable energy and appropriate for small-scale industries. It is compact, which further reduces maintenance and refurbishing costs.

LUX facilitates On-Site Clean Liquid Hydrogen Production

UK-based startup LUX enables on-site and on-demand clean liquid hydrogen production for transportation, energy, and manufacturing industries with T-100, a vertically integrated, containerized system to produce and liquify hydrogen.

It stores and supplies liquid hydrogen for refueling and eliminates the need for fuel transportation. The modular system is deployable at any location, which enables a wider adoption of clean hydrogen.

9. Blue Hydrogen

Blue hydrogen enables the production of while reducing the amount of CO2 in the environment. Also known as low-carbon hydrogen, it plays an important role in decarbonizing major industries like transport, steel making, ammonia production, oil refining, and more.

A few common methods for blue hydrogen production include autothermal reforming and partial oxidation.

Kellas Midstream and SSE Thermal partnered for the project H2NorthEast, which will deliver 355 megawatts of low-carbon hydrogen to the local industries. Saudi Arabia is also increasing its investment in blue hydrogen production.

The blue hydrogen market size is expected to reach USD 27 billion in 2032 at a CAGR of 49.1% from 2024 to 2032.

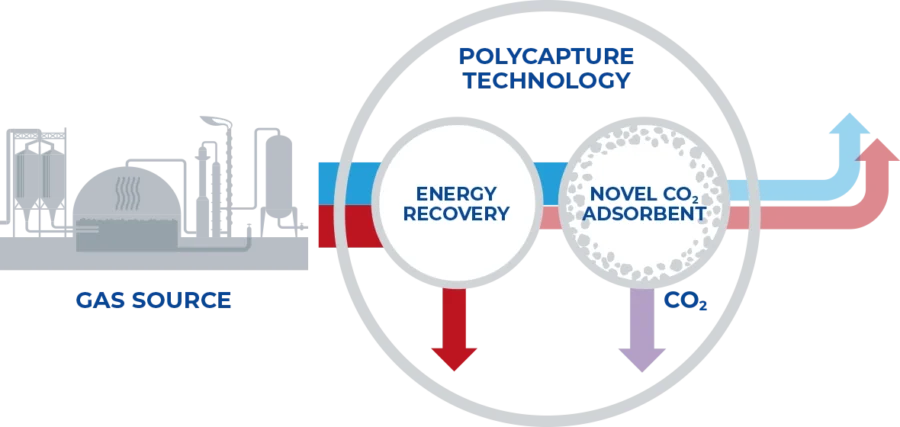

PolyCapture designs a Polymer CO2 Adsorbent for Blue Hydrogen Production & Purification

UK-based startup PolyCapture develops a patented polymer CO2 adsorbent for producing and purifying blue hydrogen. It is highly selective and uses pressure or temperature swing adsorption (PSA and TSA) to separate CO2 from other gases like nitrogen, methane, and hydrogen. The CO2 adsorbent eliminates the need for further purification as its selectivity ensures high purity hydrogen gas.

The process starts by flowing the flue gas through the bed of patented polymer beads, which absorb the CO2. Once the beads reach their highest capacity of adsorption, the flow of flue gas is switched to a second bed. It is then purged to remove excess raw gas and improve the purity of the CO2 stream.

Finally, the pressure reduction of the system releases CO2 from the beads. The CO2 adsorbent polymer is non-corrosive and resilient to gas impurities and water vapor as well as provides a low levelised cost of capture.

Hydron Energy streamlines Clean Hydrogen Generation

Canadian startup Hydron Energy builds a regeneration upgrading platform technology, INTRUPTor, for biogas upgrading, clean hydrogen production, rare gas production, and carbon capture.

The technology uses proprietary parallel passage contractors, a rapid regenerative cycle, a dynamic rotary valve, and system integration and control as core elements. The startup’s sorbents enable the parallel passage of contractor sorbent architecture and ensure faster cycle speeds.

Nano-structure sorbents also enable low regeneration energy for gas separation, along with selectivity and high capacity. The parallel passage contractors ensure faster gas diffusion, low-pressure drop laminar flow gas passages, and no material wear for stagnant sorbent architecture.

The rotary valves additionally ensure efficient gas switching between sorbent beds and capture the increased capacity of the sorbents. The technology is suitable for the hydrogen sector, agricultural sector, wastewater treatment, and facilities converting renewable energy to fuel.

10. X-to-Hydrogen-to-X

X-to-hydrogen-to-x refers to the conversion of various feedstock into hydrogen gas and vice versa, like wind-to-hydrogen-power or solar-to-hydrogen-mobility. This approach mitigates the dependency on fossil fuels for clean energy and addresses the increase in demand for energy transition. Further, it enables the wider adoption of hydrogen at various operational capacities.

Companies are developing technologies to turn various products like biomass, plastic waste, sewage sludge, and lignocellulosic biomass into hydrogen gas. Similarly, industries like mining, construction, logistics, and utility are using hydrogen gas for electric power systems, transportation, industrial processes, and more.

Haru Oni from Siemens Energy develops a chemical-neutral efuel from wind and solar energy. Siemens also launched HYFLEXPOWER, an integrated power-to-X-to-power hydrogen gas turbine.

Other companies, like Air Products and Chemicals, Nel ASA, Royal Dutch Shell, and more, also contribute to the power-to-X (P2X) hydrogen programs.

H Cycle facilitates Thermal Conversion of Non-Recyclable Waste to Hydrogen-Rich Gas

US-based H Cycle produces carbon-neutral hydrogen from biomass, forest wood waste, and post-recycling material from municipalities using thermal conversion. After sorting the waste at recycling facilities, H Cycle receives the non-recyclable waste, which is again sorted.

The startup uses an emissionless technology that thermally converts the solid wastes into synthesis gas, which is then converted to hydrogen-rich gas. The hydrogen goes through purification and compression before it is ready for transportation and other industrial applications.

HiTES Holding advances Biomass to Hydrogen Conversion

German startup HiTES Holding converts biomass like wood residue from forestry, green waste, and wood waste to hydrogen gas using allothermal gasification.

The startup converts the biomass to synthesis gas at 1200 degrees Celsius. The components of the synthesis gas contain hydrogen gas, which is separated for further applications. The process also produces CO and methane, a byproduct, which generates and superheats steam for biomass drying.

Steam reforming biomass for producing hydrogen leaves a significantly smaller carbon footprint than steam reforming methane or natural gas. Along with a smaller carbon footprint, the reactor consumes less power to run and provides hydrogen at a lower price.

Discover all Hydrogen Economy Trends, Technologies & Startups

Future hydrogen trends include natural hydrogen exploration, low-carbon ammonia, and further accelerating the production of eco-friendly hydrogen. Additionally, the research and development of renewable sources of hydrogen production will also increase. These trends will increase the number of industries using hydrogen as a primary energy source.

The Hydrogen Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

WATCH THE VIDEO VERSION

WATCH THE VIDEO VERSION