Industry 5.0 trends mark the evolution of the fifth industrial revolution, building on Industry 4.0’s foundation. While Industry 4.0 emphasizes efficiency and automation, Industry 5.0 prioritizes human-machine collaboration, sustainability, and resilience. Advanced technologies like artificial intelligence (AI), the Internet of Things (IoT), extended reality (XR), and robotics enable smarter, faster, and safer manufacturing.

Industry 5.0 integrates AI with human intuition to augment skills and decision-making without replacing workers. Collaborative robots lead this trend by working alongside humans to enhance productivity and safety. IoT sensors and edge devices connect production processes and machines to support real-time monitoring and proactive supply chain control.

Mass customization or hyperpersonalization has emerged as a key trend aligned with Industry 5.0’s focus on human-centric and flexible manufacturing. As customization increases, quality assurance ensures that individual items meet established standards. Sustainability remains central, emphasizing energy efficiency, circular economy practices, and environmentally friendly innovations.

What are the Top 10 Industry 5.0 Trends in 2025?

- Human-Centric AI

- Resilient and Agile Supply Chains

- Cobots

- Internet of Everything

- Green Technology

- Hyper-Personalization

- Digital Sovereignty and Cybersecurity

- Extended Reality

- Quality Assurance

- Edge Analytics

Methodology: How We Created the Industry 5.0 Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 7M+ global startups, 20K technologies & trends plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative trends in the Industry 5.0 industry.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures that our reports provide reliable, actionable insights into the future of the Industry 5.0 innovation ecosystem while highlighting startups driving technological advancements in the industry.

Innovation Map outlines the Top 10 Industry 5.0 Trends & 20 Promising Startups

For this in-depth research on the Top Industry 5.0 Trends & Startups, we analyzed a sample of 2770+ global startups & scaleups. The Industry 5.0 Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the Industry 5.0 trends & startups that impact your company.

For this in-depth research on the Top 10 Industry 5.0 Trends & Innovations, we analyzed a sample of 2770+ startups & scaleups from different regions around the world. The Industry 5.0 Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you insights like trends on which a startup is working, products or services being offered, and more.

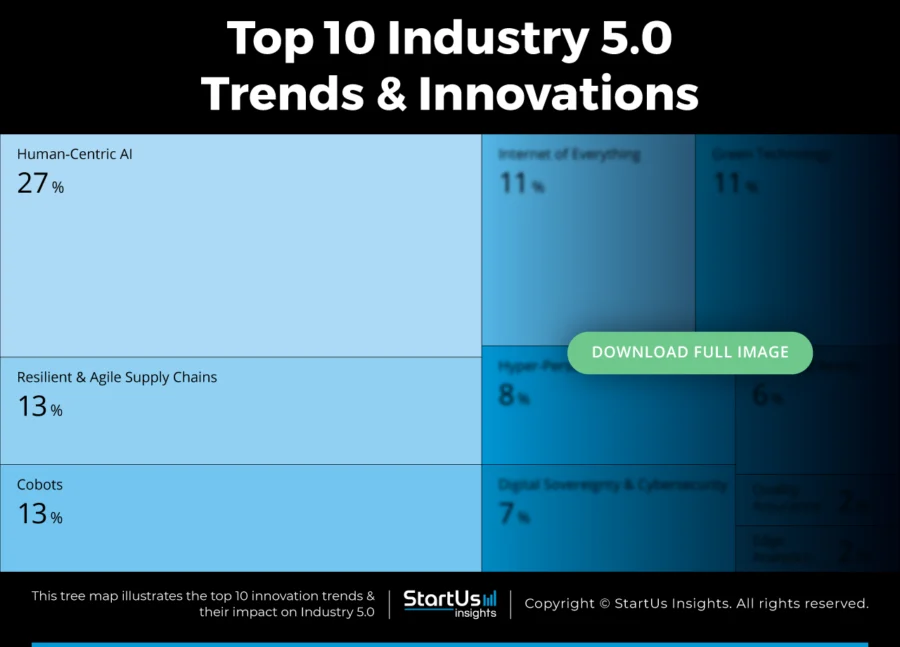

Tree Map reveals the Impact of the Top 10 Industry 5.0 Trends

Based on the Industry 5.0 Innovation Map, the Tree Map below illustrates the impact of the Top 10 Industry 5.0 Trends. Startups and scaleups are developing a collaborative environment for humans and AI systems to work together for optimal output. Cobots reinforce such human-machine collaboration, allowing humans to focus on creativity and decision-making.

Many IoT and edge computing solutions are coming to allow real-time data processing and analysis. Businesses must keep their supply chains agile and resilient for a customer-centric approach and accommodate hyper-personalized production. A proactive approach to product quality management as well as ethical practices is also essential aspects of industry 5.0.

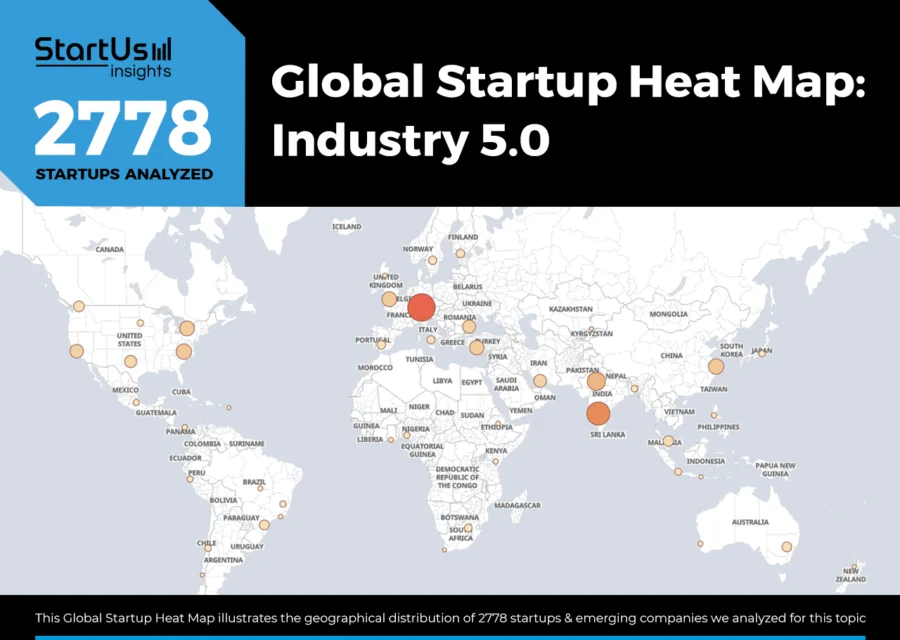

Global Startup Heat Map covers 2770+ Industry 5.0 Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 2770+ exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in India and the US, followed by Turkey. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Industry 5.0 Innovations & Trends?

Top 10 Emerging Industry 5.0 Trends [2025 and Beyond]

1. Human-Centric AI

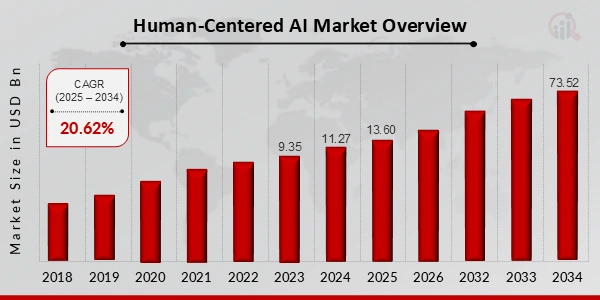

The human-centered AI market is expected to grow from USD 13.60 billion in 2025 to USD 73.52 billion by 2034, with a compound annual growth rate (CAGR) of 20.62% during the forecast period.

Credit: Market Research Future

McKinsey reports that 92% of companies plan to increase AI investments between 2024 and 2026. In the manufacturing sector, 82% of manufacturers aim to increase their AI budgets in 2025, with nearly a quarter planning spending hikes of 26–50%. This shift highlights efforts to integrate human-centric AI systems into production lines and decision-making.

The European Commission launched Horizon Europe R&D calls, allocating EUR 112 million to AI and quantum technologies. Of this, EUR 15 million focused on improving AI transparency and reliability to support Europe’s commitment to trustworthy AI under the AI Act.

In India, IIT Madras established the Centre for Human-Centric AI to emphasize responsible AI, large language models, and collaboration between academia, government, and industry for Industry 5.0-aligned solutions.

Robotics adoption is growing, particularly in collaborative robots (cobots). Cobots now identify human gestures and proximity and adjust operations with features like dynamic speed governors and force-limited actuators to enhance safety.

Further, AI increasingly assists human decision-making in industrial settings. AI systems optimize processes such as predictive maintenance, real-time production, and quality control analytics.

For example, predictive AI models warn technicians of machinery risks and suggest maintenance schedules to reduce downtime and improve efficiency.

Sensor and perception technologies are also advancing rapidly, enabling AI systems to interpret human behavior and environmental contexts effectively. Robots and digital assistants now understand human intentions better, adapting to shared environments and enhancing cooperative workflows.

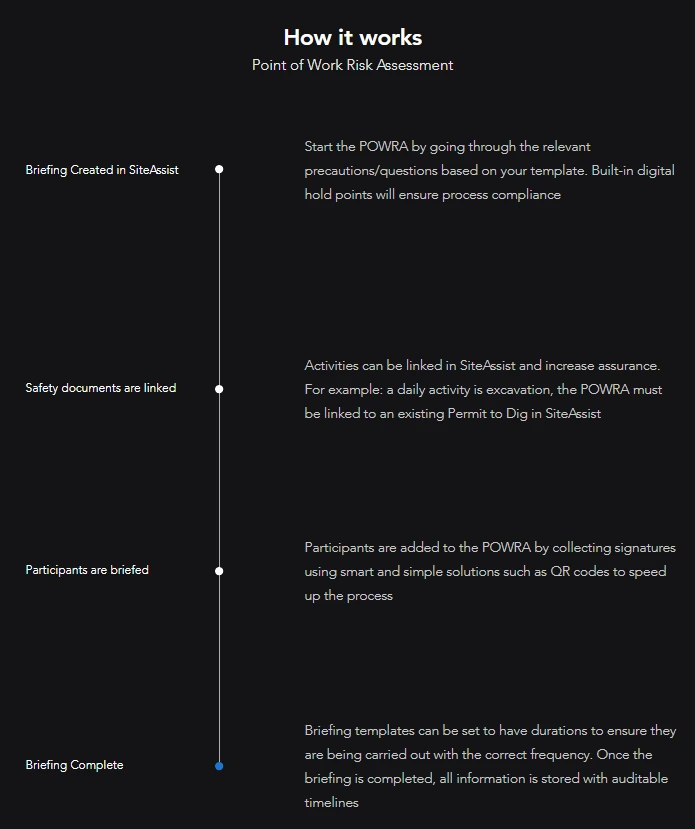

SiteAssist enhances Industrial Safety

UK-based startup SiteAssist offers an AI digital platform for high-risk industries like construction, nuclear power, oil & gas, and more.

Its Smart Permits module records on-site data, including precise time and geolocation data, enabling easy inspectability. Its geolocation technology displays where the work is taking place on the shop floor in real time to prevent clashes.

It also deploys machine learning algorithms to identify duplicated images in safety documents to ensure compliance. Its Checklist tool connects to multiple safety processes, ensuring complete audibility.

Further, its module Register acts as a cloud-based Microsoft Excel, which digitizes and integrates workflows, giving access to industrial information at all times to stakeholders.

Maneva designs Industrial AI Copilot

Canadian startup Maneva brings an autonomous AI-powered digital workforce for manufacturing. Maneva Quality automatically detects defects, foreign materials, and discoloration in products based on machine learning algorithms to promote production quality. It provides custom support in the form of live warning indicators, bulk divertors, robotic rejection systems, and more.

Another feature, Maneva Automate, automates pick-and-place operations and provides immediate insights into production data. This enables users to optimize processes and reduce waste.

Further, Maneva Mechanic initiates predictive maintenance of conveyor belts to reduce downtime. Additionally, Maneva Safety monitors the facility’s handwash routine and ensures the adoption of health and safety practices. This way, the startup’s AI workforce reduces labor dependencies, cuts costs, and improves productivity.

2. Resilient and Agile Supply Chains

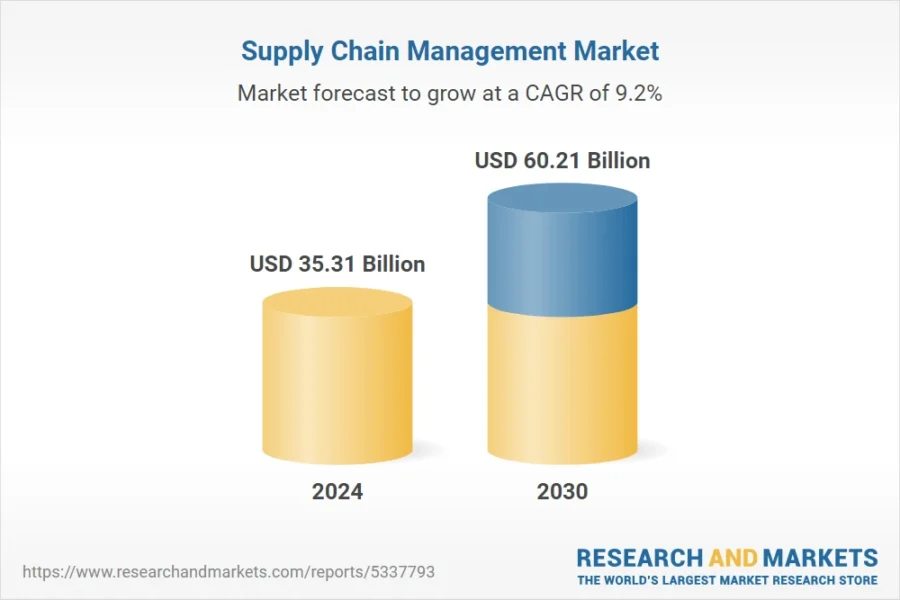

The supply chain management (SCM) market was valued at USD 35.31 billion in 2024. It is expected to grow at a CAGR of 9.24%, reaching USD 60.21 billion by 2030.

Credit: Research and Markets

Organizations are adopting human-centric models that prioritize employee empowerment and customer focus. The distributed production systems bring manufacturing closer to consumers. These changes reduce lead times, improve service levels, and lessen dependence on distant factory hubs, which makes supply chains more responsive and agile.

Global disruptions have heightened the need for risk mitigation. By early 2024, an estimated 86% of industrial manufacturers had taken steps to reduce supply chain vulnerabilities, including building buffer stockpiles and adopting dual sourcing.

A global study revealed that 97% of companies restructured their supply chain networks by the end of 2023. Many implemented near-shoring and re-shoring strategies. To mitigate risks further, 79% of firms diversified their supplier base, 71% invested in regionalization, and 83% adopted “friend-shoring,” sourcing from politically aligned nations.

Besides, analysts estimate that by 2025, 50% of large global companies will use AI, advanced analytics, and IoT to streamline logistics and operations. These technologies enable end-to-end visibility across supply chains.

Moreover, IoT sensors, cloud platforms, and connected devices enable companies to monitor shipments, track in-transit conditions, and reroute deliveries to avoid disruptions.

AI tools reduce manual workloads and support real-time decision-making. Algorithms identify anomalies in datasets, predict potential disruptions, and suggest solutions to enhance efficiency and responsiveness.

In addition, tools such as control towers and digital twins improve agility by simulating scenarios and optimizing inventory, production, and logistics responses.

Smartcube Solutions works on Supply Chain Waste Management

Norwegian startup Smartcube Solutions develops software-as-a-service (SaaS) platforms for industrial supply chain waste management.

Its I-SPIR is a modular and scalable SaaS that allows end users, vendors, and suppliers to collaborate and share spare parts interchangeability records (SPIR) in real time. This improves the accuracy of materials data across all stakeholders, resulting in reduced capital expenditures (CapEx), operating expenses (OpEx), and carbon footprint.

Another platform, I-MAT, cleans the existing supply chain data of heavy industries and prevents any unnecessary data from entering based on AI. This gives businesses control over their supply chain data for effective material management.

CommonShare enables Transparent Supply Chains

US-based startup CommonShare’s collaborative platform streamlines order traceability for suppliers and retailers. Manufacturers input product tracking data into the platform directly, eliminating duplication and audit fatigue due to multiple data entries.

The platform then automatically verifies adherence to compliance standards and ethical guidelines. It also provides real-time alerts and footprinting insights for implementing more sustainable practices across the supply chain.

3. Cobots

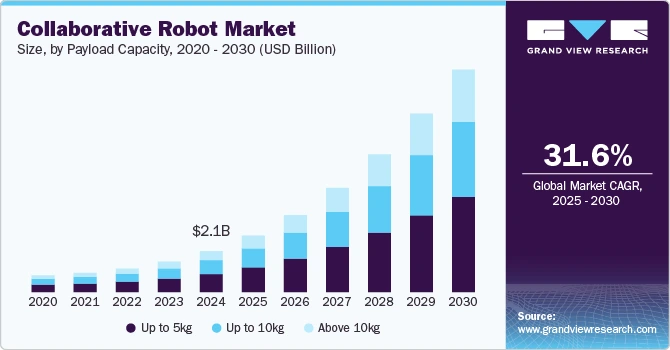

The global cobot market was valued at USD 2.14 billion in 2024 and is projected to grow at a CAGR of 31.6% from 2025 to 2030. Another forecast sees the market reaching USD 5.8 billion by 2030 with 150 000 units shipped annually.

Credit: Grand View Research

Cobots represented 10.5% of all industrial robot installations in 2023, marking substantial growth compared to a decade ago. This rise corresponds with technological improvements between 2024 and 2025.

Modern cobots incorporate safety features such as force-limited joints, AI-powered vision systems, and proximity sensors. These features allow shared workspaces without physical barriers by detecting human presence and adjusting behavior to ensure safe interactions.

Besides, the integration of AI and 3D vision technologies has enhanced cobots’ collaboration with people. These capabilities enable cobots to interpret gestures, navigate changing environments, and adapt to tasks in real time, which increases their ease of deployment and operation.

Companies now use cobots for physically demanding tasks like palletizing and packaging, where robots handle repetitive or heavy lifting, while humans focus on supervisory or lighter work. This collaboration reduces workplace injuries and fatigue, while improving productivity and workforce well-being.

Universal Robots launched the UR30, a 30-kg payload cobot designed for heavy-duty tasks like high-torque assembly and palletizing. The company also introduced an “AI Accelerator” toolkit in 2024 to integrate AI seamlessly into cobot workflows to increase intelligence and versatility.

Moreover, cobots are becoming indispensable in high-mix, low-volume production environments, where agility and product variety are critical. Using intuitive interfaces like tablet controls and hand-guiding, cobots are quickly reprogrammed and redeployed to support frequent product changeovers without long setup times.

Their adaptability and usability make them valuable for small and medium-sized enterprises (SMEs) and custom manufacturing applications.

RBW aids Welding

South Korean startup RBW manufactures cobots for autonomous welding, grinding, palletizing, and more. Its RB-MIG is a metal inert gas (MIG) welding tool equipped with sensors enabling an intuitive robot teaching experience, reducing teaching times. The fiber-built RB-LASER offers faster weld speeds than conventional tungsten inert gas (TIG) for sheet metal applications.

Further, RB-GRIND facilitates high-speed grinding and deburring. All the above cobots are also designed to allow users to schedule various program sequences and execute them in their preferred order. This way, the startup’s solutions improve work speed and accuracy, while reducing labor costs and downtimes.

Genitor develops AI-driven Cobot

US-based startup Genitor manufactures an AI-driven material movement cobot, Proxie, for logistics, hospitals, and manufacturing operations. Proxie uses light detection and ranging (lidar)-based visual perception to autonomously navigate within industrial facilities.

Equipped with simultaneous localization and mapping (SLAM), it maps the surroundings in real time to avoid people, obstacles, and accidents. The cobot understands a natural human command, making it interactive and convenient to deploy.

Further, it comes with a Flex Grasp gripper for handling carts, loading or unloading boxes, and more. This reduces the risk of injuries to workers from heavy lifting, repetitive strain, or hazardous materials. It also features AI-based fleet optimization, allowing workers to execute tasks efficiently with reduced downtime.

4. Internet of Everything

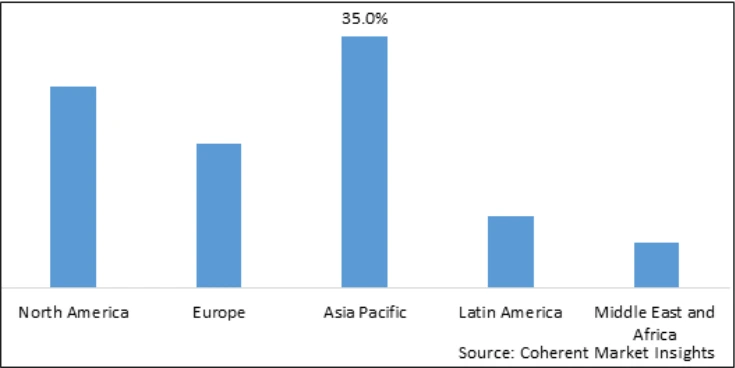

The Internet of Everything (IoE) market is expected to grow from USD 1604.89 billion in 2025 to USD 4321.28 billion by 2032, at a CAGR of 15.2%.

Credit: Coherent Market Insights

IoE is reshaping manufacturing by introducing integrated smart factory ecosystems. 95% of manufacturers will use or evaluate smart factory technologies by 2025, up from 83% the previous year.

In addition, 94% plan to maintain or expand their workforce as they adopt automation, which reflects a shift toward collaboration between humans and machines rather than labor replacement.

Besides, IoE-powered production lines, equipped with sensors and wearables, enhance workers’ capabilities and support adaptability to operational changes.

The connection of machine, product, and employee data streams enables decision-making directly on factory floors. These systems support predictive maintenance, adaptive scheduling, and process optimization, resulting in improved performance indicators such as productivity, cost savings, and overall equipment effectiveness (OEE).

Further, enhanced digital visibility across production and supply chains is improving planning. By 2025, 78% of manufacturers are expected to deploy advanced planning systems that increase supply chain transparency and responsiveness.

These systems monitor operations in real time, detect anomalies, and provide predictive insights to reduce downtime and improve efficiency.

Melody Innovations promotes Industrial Automation

Indian startup Melody Innovations develops IoT hardware for industrial connectivity. Its product lineup includes the Melody Gateway and Melody Edge devices. These modular IoT devices feature over-the-air firmware updates, ensuring they remain up-to-date without the need for manual intervention.

Each device is equipped with LED indicators for easy monitoring and troubleshooting. They support integration with energy meters using the Modbus protocol, enhancing energy management capabilities.

Further, their tamper-proof design maintains data integrity and device security in industrial environments. This way, the startup’s products support various standard protocols and communication interfaces for industries such as manufacturing and cold storage.

Edgenesis IoT and Edge AI Solutions

US-based startup Edgenesis specializes in Kubernetes-native Edge AI and IoT solutions. Its edge platform, Shifu, virtualizes IoT devices into Kubernetes pods, providing an all-in-one Kubernetes cluster that coordinates IoT devices and applications at the same time.

This enhances the control of edge devices and offers application developers a unified base for cloud-edge collaborative management.

Another solution, IoT Driver Copilot, is a copilot for developing IoT device drivers. Based on a generative pre-training transformer (GPT), it reduces the time required to develop device drivers, enhancing developer productivity.

5. Green Technology

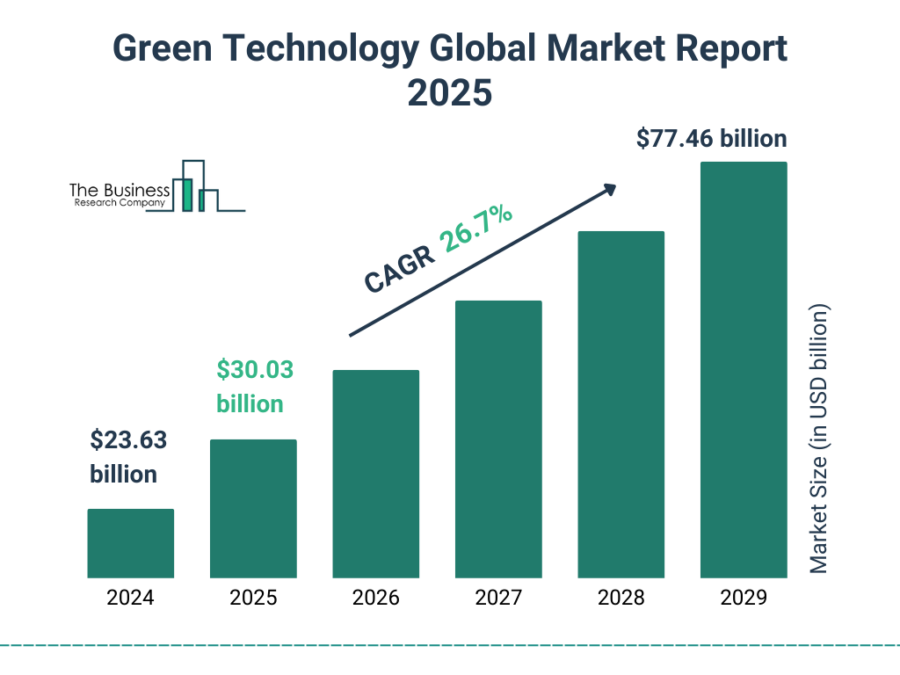

The green technology market is expected to grow to USD 77.46 billion by 2029, with a CAGR of 26.7% during the 2025–2029 period.

Credit: The Business Research Company

This growth reflects efforts by industries to decouple economic progress from environmental impact, particularly in sectors like heavy industry and transport, which contribute about 40% of global CO₂ emissions.

Manufacturers are transitioning to clean energy sources to address these challenges. The share of renewables in global electricity generation rose from 23% in 2023 to 24% in 2024, indicating wider use of solar, wind, and hydro power for industrial applications.

At the same time, circular economy principles are gaining traction to reduce waste and emissions. Manufacturers are redesigning products for reuse, incorporating recycled materials, and extending product lifespans.

In Europe, circularity efforts raised the recycled material usage rate to 11.8% to strengthen supply chain resilience and support Industry 5.0 sustainability goals.

Moreover, deploying advanced emissions monitoring systems remains central to green industrial transformation. The continuous emission monitoring systems (CEMS) market reached USD 4.3 billion, driven by widespread use of real-time sensors and Industrial IoT devices. These systems accurately track energy use and carbon emissions on factory floors.

AI optimization tools are further advancing efficiency by enabling data-driven operational adjustments. For example, an automotive plant reduced energy consumption by 15% through AI-powered real-time energy management.

Similarly, predictive maintenance and smart scheduling cut downtime and shifted workloads to off-peak hours, saving 12% on energy costs.

In addition, innovations such as waste-heat recovery systems have lowered fuel consumption by about 20%. Combined heat-and-power (CHP) installations have improved facility energy efficiency from approximately 50% to 75%.

Cocoon introduces a Climate Technology Platform

UK-based startup Cocoon offers low-carbon construction materials for the heavy industries. Through its proprietary process, Cocoon upcycles industrial waste like steel slag, biomass ash, fly ash, mine tailings, and demolition waste into sustainable cement.

This reduces carbon emissions and landfill waste. It also allows manufacturers to lower CO2 taxes and waste management costs by transforming waste streams into revenue opportunities.

Mitico boosts Carbon Capture

US-based startup Mitico offers industrial point-source carbon capture through a proprietary chemical sorbent. The sorbent is based on non-toxic potassium carbonate (K₂CO₃), which is efficient at absorbing CO2. This technology collects and purifies CO2 at the source post-combustion before it enters the atmosphere.

The startup’s solution is also retrofittable into existing industrial temperature swing adsorption (TSA) tower reactors as a plug-and-play system. This facilitates uninterrupted stream processes without any modifications while capturing carbon emissions.

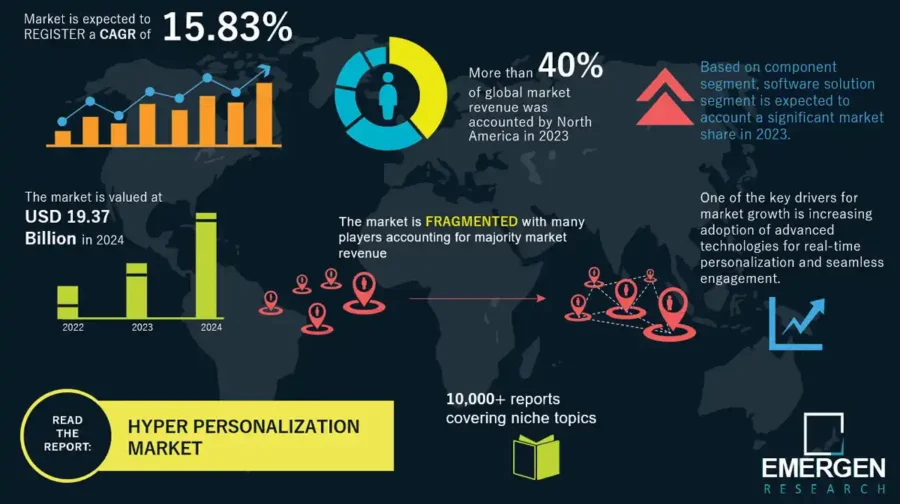

6. Hyper-Personalization

The global hyper-personalization market was valued at USD 19.37 billion in 2024. It is projected to grow at a CAGR of 15.83% through 2033, driven by increased demand for bespoke products and manufacturers’ focus on mass customization.

Credit: Emergen Research

BMW Group exemplifies this transformation by producing approximately 2.5 million vehicles annually, with 99% built to order based on customer specifications.

Managing this complexity requires more than flexible production lines. BMW uses real-time digital twin simulations to optimize assembly sequences and resource allocation for each order.

Manufacturers across industries are adopting configure-to-order (CTO) and engineer-to-order (ETO) models. These approaches rely on digital threads—continuous data flows linking design, engineering, and production, which enable quick design changes while maintaining operational efficiency.

Further, AI algorithms analyze customer preferences and translate them into actionable instructions, while smart robotics adjusts workflows to meet custom requirements.

Digital twins play a central role in accelerating design and engineering. They let engineers simulate design iterations and production outcomes in hours to cut development cycles significantly.

Early adopters report reducing product development timelines by up to 50%, which speeds up time-to-market for customized goods while ensuring quality and manufacturability.

Besides, 3D printing technologies are making one-off production economically feasible. Instead of retooling production lines for each variation, manufacturers use additive manufacturing to create complex, custom components on demand. This flexibility supports mass personalization in sectors like automotive, aerospace, consumer electronics, and healthcare.

Hyper-personalization also strengthens customer loyalty and pricing power. A recent survey showed that 1 in 5 consumers is willing to pay a 20% premium for personalized products, while nearly 50% are ready to wait longer for items that reflect their preferences.

Prima offers Custom Manufacturing

Mexican startup Prima manufactures customized parts and goods. Its capabilities include CNC machining, sheet metal fabrication, welding, die casting, plastic injection molding, and more.

It centralizes manufacturing and supply chain operations for operational resilience and flexibility to serve industries like industrial equipment, mining, construction, and retail. The custom design ensures compatibility with existing systems and processes.

goatAM manufactures Pharmaceutical 3D Printers

German startup goatAM develops a 3D printer, doprOne, to produce patient-tailored drugs at local pharmacies or hospitals. doprOne adheres to medication specifications defined by the clinician to ensure safety in the production of drugs.

This approach allows for precise tailoring of active ingredients and dosages to individual patient needs, improving treatment effectiveness and minimizing side effects. It also deploys AI-based analysis to predict product quality and optimize process parameters.

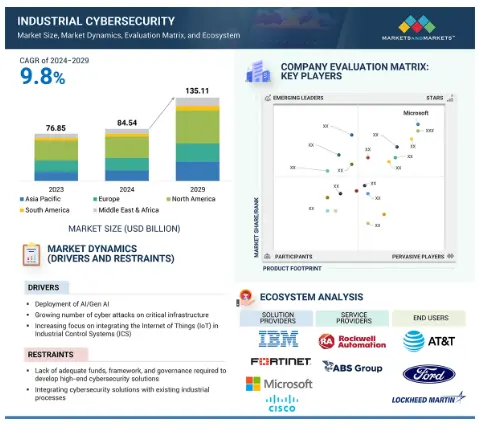

7. Digital Sovereignty and Cybersecurity

The global industrial cybersecurity market is expected to grow from USD 84.54 billion in 2024 to USD 135.11 billion by 2029, with a CAGR of 9.8%.

Credit: Markets and Markets

Manufacturers face growing risks from cybercriminals, with industrial ransomware attacks rising 87% year-over-year. Nearly 70% of industrial cyber incidents now target the manufacturing sector, which leads to production disruptions, intellectual property theft, and financial losses.

Digital sovereignty has become a key priority as organizations seek control over their data, infrastructure, and operations. It ranked among the top three security concerns for enterprises, driven by geopolitical instability and fragmented supply chains. Manufacturers are reducing reliance on third-party providers and strengthening their technology ecosystems.

New regulations in 2024 have amplified the need for cybersecurity updates. The EU AI Act sets strict requirements for high-risk AI systems in industrial settings, including transparency, safety, and human oversight. This pushes manufacturers to redesign workflows and integrate risk management strategies for AI-based decision-making.

At the same time, the NIS2 Directive has extended its scope to classify manufacturing as critical infrastructure. This directive requires manufacturers to strengthen cyber risk management, secure supply chains, and report incidents within 24 hours. These changes are prompting firms to evaluate compliance, invest in security capabilities, and work closely with regulators.

Supply chain vulnerabilities remain a major challenge. Over 80% of organizations experienced supply-chain-related breaches in the past year. In response, 86% of enterprises have raised budgets for third-party cybersecurity and now demand stricter vendor compliance.

Moreover, manufacturers are conducting security assessments to enforce contractual requirements and ensure visibility into supplier networks to manage cascading risks effectively.

Valarian accelerates Digital Sovereignty

UK-based startup Valarian offers data sovereignty infrastructure to safeguard sensitive data for commercial enterprises, government institutions, and defense sectors.

It allows users to localize their data anywhere globally while meeting compliance with local regulations. This gives the flexibility to operate anywhere without compromising data protection.

The startup’s platform integrates access controls, allowing users to authorize individuals who interact with sensitive data, thereby minimizing the risk of breaches. It also provides audit logging and e-discovery capabilities to guarantee that every action is logged and traceable, thus preserving data integrity.

RVBionics automates Cybersecurity

Chilean startup RVBionics specializes in industrial cyber defense solutions for smart factories. Its flagship product, Securics, utilizes cloud-native architecture to provide high-speed connectivity and scalability for data protection across operational technology (OT), industrial control systems (ICS), and IIoT infrastructure.

It also leverages self-learning AI to learn from new attack patterns and evolve without requiring manual updates. This enables proactive detection and mitigation of threats in real time.

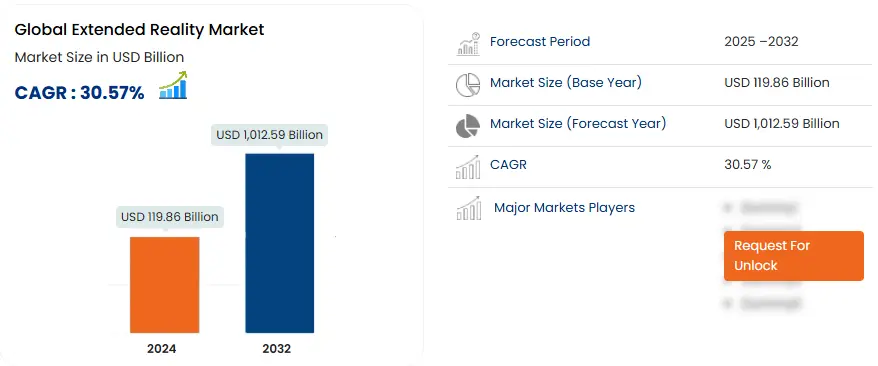

8. Extended Reality

The global extended reality (XR) market was valued at USD 119.86 billion in 2024. It is expected to grow to USD 1012.59 billion by 2032, with a CAGR of 30.57% from 2025 to 2032.

Credit: Data Bridge Market Research

In workforce development, XR is changing employee training and onboarding. Virtual reality (VR) simulations and augmented reality (AR) tools immerse workers in hands-on scenarios. These methods allow employees to interact with virtual equipment, practice complex tasks, and build skills in safe environments.

For instance, Walmart’s use of VR training improved trainee test scores by 10–15% to enhance knowledge retention and confidence. This approach speeds up onboarding, reduces errors, and prepares workers more effectively across industries.

AR is also improving equipment maintenance and field operations. AR headsets provide on-site technicians with real-time remote guidance through digital overlays on machinery.

These tools have reduced equipment downtime by up to 50%, increased technician productivity by 25%, and decreased accident rates by 12%. In addition, incident response times have dropped by 60%, highlighting AR’s role in promoting operational continuity and safety.

In design and engineering, mixed reality (MR) enables remote collaboration by connecting geographically dispersed teams with 3D prototypes in real time.

Approximately 52% of XR applications in manufacturing focus on product design and development. These tools allow teams to identify flaws earlier, iterate faster, and rely less on physical prototypes, which shortens development cycles and supports cost-effective innovation.

Moreover, AR integrates industrial internet of things (IIoT) data with physical assets on factory floors to support real-time, data-driven decisions. AR visual cues guide operators through complex tasks with greater precision, reducing errors and improving output quality.

In real-world applications, AR-guided workflows have lowered assembly errors, demonstrating XR’s ability to connect digital and physical processes for improved efficiency.

AtlasVR provides Industrial VR Training

Swiss startup AtlasVR facilitates VR training for the mechanical, electrical, and metal (MEM) and building technology industries. It provides controllers and a VR headset pre-loaded with tailored software, making the equipment ready to use, and allowing businesses to begin training immediately.

VR trainees learn tasks such as operating complex production machines in an interactive virtual environment without the risk of health or equipment damage. Moreover, the startup’s solution allows engagement in training sessions even before the actual equipment is available on-site.

The immersive nature of VR minimizes learning fatigue. It also ensures that accidents or errors have no real-world consequences or costs.

EXARON innovates 3D Simulation

Austrian startup EXARON specializes in 3D capturing, modeling, and simulation of industrial processes. The startup captures industrial data using technologies like 3D laser scanning, gaussian splatting, and SLAM to create digital twins of the physical environment. This digital simulation helps evaluate workflows for process optimization.

The startup also deploys extended reality for virtual presentations, interactive meetings, testing, and training of prototypes and products. This reduces the decision and acceptance phase, downtime, as well as resource consumption.

9. Quality Assurance

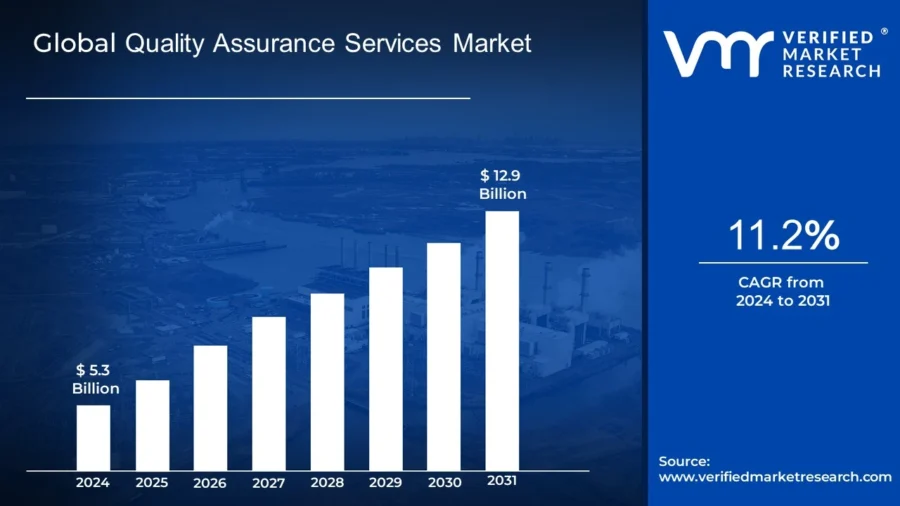

The quality assurance (QA) services market was valued at USD 5.3 billion in 2024 and is expected to reach USD 12.9 billion by 2031, growing at a CAGR of 11.2%.

Credit: Verified Market Research

Manufacturers are increasingly using AI, computer vision, and digital twin simulations to improve QA strategies.

Instead of relying on post-production inspections, these technologies enable real-time, predictive quality control by automating defect detection and flagging anomalies during production. This allows skilled personnel to concentrate on oversight, root-cause analysis, and process refinement, aligning with Industry 5.0’s human-centric approach.

LG Electronics adopted a digital twin and analytics-based QA solution, which reduced defective product returns by 70% within a year.

AI-powered vision systems also improved product consistency by 35% to ensure adherence to quality standards and lowering customer dissatisfaction.

Besides, operational savings accompany these quality improvements. AI-driven quality control minimizes rework, waste, and warranty claims, leading to cost efficiency while supporting sustainability goals through reduced resource use.

Intelligent QA systems provide real-time feedback on defects and deviations to enable production lines to self-correct with minimal human input.

Moreover, at an HPE facility in Europe, a custom deep learning-based QA system for server assembly lowered out-of-the-box quality issues by 25%. This system validated 1000 server configurations and reduced inspection time by 96 seconds per unit, allowing technicians to focus on value-added tasks.

DeepQual facilitates Automatic Inspection

French startup DeepQual specializes in automated inspections and business intelligence for the construction industry. It offers a mobile app based on AI and lidar sensors that enables fast quality checks on construction sites, eliminating subjective errors due to manual inspections. This reduces rework, material waste, and labor costs associated with fixing unnoticed defects.

Further, AI-based compliance checks verify plans as per industry standards, reducing the risk of non-compliance. This flags issues before they escalate into major problems.

Velma Factory Systems brings a Production Management System

Ghanaian startup Velma Factory Systems provides a cloud-based factory management system for production management and quality control.

The startup’s software tracks products and processes throughout production, ensuring compliance with regulations. It offers real-time monitoring and alerts in case of discrepancies to ensure production quality.

Velma’s platform is customizable to meet the specific needs of industries like food and beverage production, fast-moving consumer goods (FMCG), bakery and confectionery, meat production, and more.

10. Edge Analytics

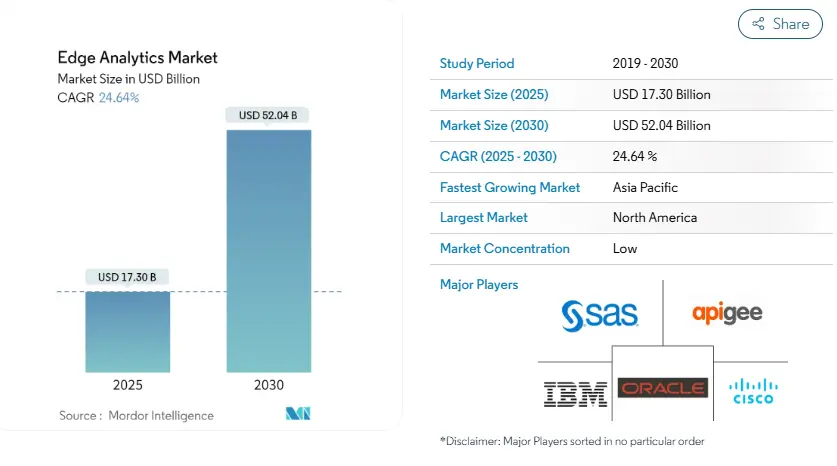

The edge analytics market is expected to grow from USD 17.30 billion in 2025 to USD 52.04 billion by 2030, CAGR of 24.64% during the forecast period.

Credit: Mordor Intelligence

Private 5G infrastructure adoption in factories increased significantly in 2024. It provides ultra-low latency and high-bandwidth connectivity for edge computing, moving manufacturers away from traditional wired networks. This enables real-time data flows from sensors and machines directly to edge processors.

Airbus demonstrated this approach by deploying private 5G to connect thousands of devices across a 3.6 km² facility to improve data throughput and operational responsiveness compared to Wi-Fi.

Further, wearable technologies, such as industrial AR glasses and voice-activated assistants, are becoming more integrated with edge computing platforms. These devices deliver frontline workers instant access to contextual analytics, including machine health data and guided instructions to enhance safety and efficiency.

Edge analytics ensures the displayed data remains current, even in bandwidth-constrained or offline settings, strengthening human-machine collaboration on the shop floor.

Moreover, at Bosch’s Blaichach plant in Germany, Nexeed edge systems reduced production line disruptions by 25% in the Electronic Stability Program (ESP) manufacturing unit.

Similarly, GE Vernova’s Proficy for Sustainability solution reduced HVAC-related energy use by 18% at a European auto-parts facility by adjusting heating parameters in real time.

In addition, edge-controlled systems for smart lighting and compressed air management achieved significant energy savings during pilot projects. These developments reflect a growing focus on integrating sustainability goals into operational decision-making, supported by edge analytics and strong network infrastructure.

Polychip advances Edge Computing

German startup Polychip specializes in IoT and edge computing solutions. Its software library, edgeCollect | edgePredict, facilitates data collection and processing from various sensors and equipment. This allows for predictive maintenance, condition monitoring, remote control, and resource consumption monitoring.

The startup also works on a digital twin, polyTwin, which connects to multiple IoT platforms and clouds to create a virtual replica of physical assets and processes. It allows businesses to optimize performance by simulating real-world conditions and predicting future outcomes.

Aethero presents a Nano Edge Computing Module

US-based startup Aethero manufactures edge computing modules (ECMs), like NxN and NxA, for capturing, processing, and managing data in space. Aethero’s NxN-ECM offers modular, multiple redundant, or distributed computing configurations for a range of spacecraft applications, from small CubeSats to large space stations.

Its miniature design reduces the power consumption while maintaining the computing efficiency. Along with AI and machine learning (ML) software, the startup’s ECMs facilitate monitoring of targeted areas and provide access to real-time weather data.

Discover all Industry 5.0 Trends, Technologies & Startups

Industry 5.0 is still in its early stages, but it has the potential to revolutionize the production of goods and services. Technologies like AI, IoT, XR, blockchain, and 5G/6G connectivity come together to augment human intelligence and create more personalized and efficient manufacturing processes. By focusing on human-machine collaboration, resilience, and ethical practices, Industry 5.0 is paving the way for a more sustainable future.

The Industry 5.0 Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.