The manufacturing industry moves to adopt and employ new technologies that not only promote increased productivity and efficiency but also drive innovation. For example, one of these technologies, artificial intelligence, will soon grant data insight in real-time, thus supporting and instructing workers and robots in the complex manufacturing process.

Additionally, advancements in IoT, robotics, and additive manufacturing are transforming traditional production methods, enabling greater customization and agility in operations, ultimately leading to smarter, more responsive manufacturing ecosystems. These innovations ensure manufacturers can meet evolving market demands swiftly and efficiently.

This article was last updated in July 2024.

Dive into Our Data-driven Manufacturing Innovation Map

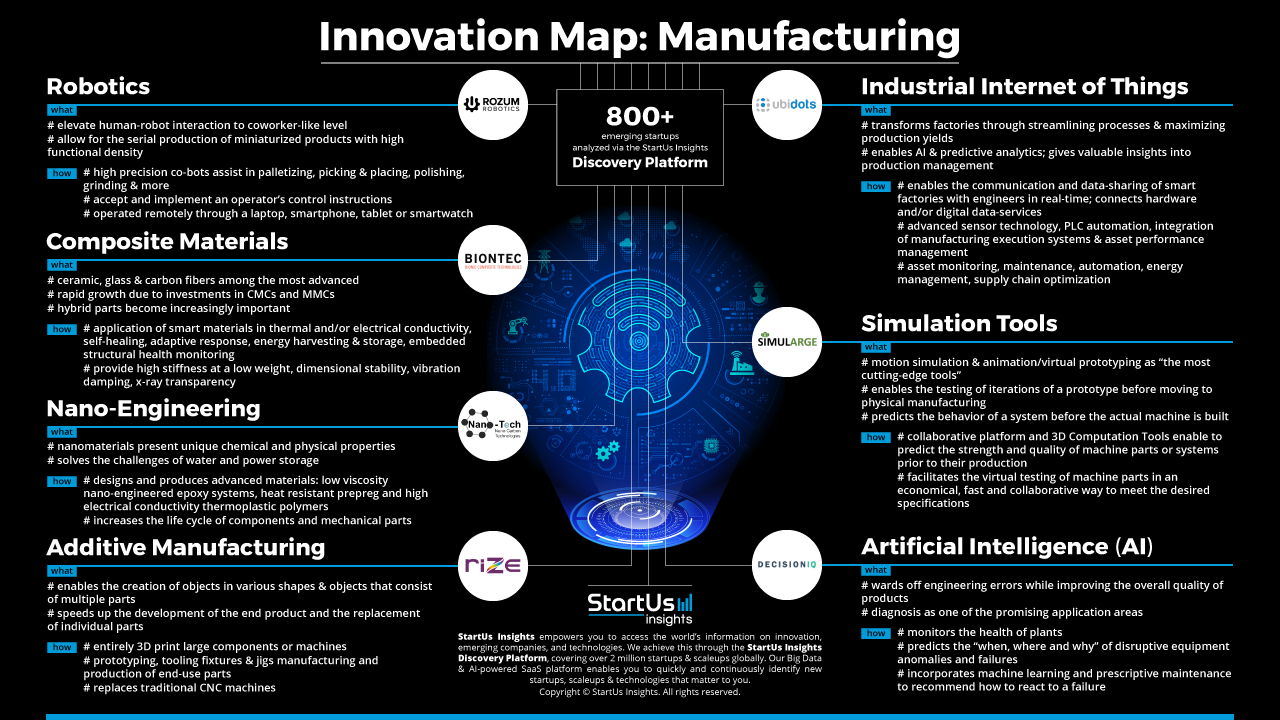

As a high number of startups work on the technologies that bring the manufacturing industry forward, we at StartUs Insights researched 800+ of them to identify key technologies and innovation areas. We reached these results using our proprietary innovation scouting approach and clustered the findings in our Manufacturing Innovation Map:

Ready to explore all 800+ Manufacturing Startups & Scaleups?

Robotics

Robot-human interaction is already prevalent in the manufacturing industry as “co-bots”, or collaborative robots, assist the human workforce with tasks such as packaging and palletizing, picking & placing, polishing, grinding, and even the assembly process among others. Current advancements made with industrial co-bots enhance human-robot interaction to a coworker-like level.

Soon, robotics will be capable to accept and implement an operator’s control instructions and inform them about the current process status. For the manufacturing process, the employment of collaborative robots means decreasing costs while quality and productivity are set to increase, allowing the serial production of miniaturized products with high functional density.

tartups working in this area focus on software solutions rather than hardware; solutions range from advanced 3D vision sensing technologies such as time of flight sensors to 3D depth sensors along with deep learning algorithms that enable robots to use eye and mind coordination.

Composite Materials

Ceramic, glass, and carbon fibers are amongst the most advanced composite materials. However, due to significant amounts of investment, ceramic fibers are expected to have the highest growth rate between 2022 and 2027 – predominantly in ceramic matrix composites (CMCs) and in metal matrix composites (MMCs) with applications varying from gas turbines and military rockets to high-performance insulation.

Although glass fiber will not grow as rapidly, in the automotive and construction industries, it already operates in high volumes. Carbon fibers, on the other hand, will maintain a steady growth rate due to a decreased price despite entering new industries.

Multifunctional or smart composites are applied in thermal and/or electrical conductivity, self-healing, adaptive response, energy harvesting & storage as well as embedded structural health monitoring.

Moving to new applications, hybrid parts become increasingly important as pure composite materials often face limitations. Through over-molding, joining, advanced coating, and interlaminar layers & sandwich cores, manufacturers can create these hybrid composite materials.

Nano-Engineering

Nanomaterials allow for the enhancement of engineered materials due to their unique chemical and physical properties. Recently, advances have been made to further improve these properties as well as to determine alternative precursors to create materials with desirable properties.

ome of these involve increasing the life cycle of components and mechanical parts (incl. magnetic & increased optical properties) to improve mechanical activity. Further, utilizing nanotechnology reduces manufacturing time and cost while it is capable of solving the challenges of water and power storage.

Looking for Specific Manufacturing Innovation Trends?

Additive Manufacturing

Initially used for prototyping, additive manufacturing (3D printing) now finds its way into the production process. Utilizing printers to print layer by layer allows production companies to create objects that consist of multiple parts as well as various shapes.

Especially useful for printing multi-material parts or parts with irregular voids and holes, 3D printing speeds up the development of the end product and the replacement of individual parts considering it contributes to downsizing the production chain. With advancements in additive manufacturing, it will soon be possible for large components or machines to be entirely 3D printed respectively to use this technology for mass manufacturing thus replacing traditional CNC machines.

Industrial Internet of Things (IIoT)

With the Industrial Internet of Things, manufacturers are presented with a technology that promises greater productivity and efficiency than ever before. As the IIoT transforms traditional factories by streamlining processes and maximizing production yields, this is hardly an innovation area to ignore.

A few of the advantages manufacturers can now benefit from include advanced sensor technology, PLC automation, asset performance management, and the integration of manufacturing execution systems. What is more, the Industrial Internet of Things acts as an enabler for artificial intelligence and predictive analytics thus creating relevant insights into production management, among others.

Simulation Tools

Described as “the most cutting-edge tools for the future of mechanical engineering”, simulation software, particularly motion simulation and animation/virtual prototyping, enables engineers to test various versions of a prototype before moving to physical manufacturing.

Torque data simulation tools allow engineers to predict the behavior of a system before it is built thus speeding up the process while also avoiding potentially expensive errors. In general, the benefits of simulation tools conclude in a cost-effective way to ensure better product performance and design satisfaction of a product.

Artificial Intelligence (AI)

Already utilized in a number of areas, diagnosis proves to be one of the most promising application areas for artificial intelligence in manufacturing. By adding new data, AI continuously improves diagnostics in order to ward off engineering errors while advancing the overall quality of products.

Meet Some of the Disruptive Manufacturing Startups

- Belarus-based ROZUM Robotics develops the human-friendly robotic arm PULSE. The 6-axis high-precision collaborative robot performs a variety of operations in warehouses and factories. It can be wirelessly operated via laptop, tablet, smartphone, and -watch therefore removing the necessity for human presence in the workspace.

- BIONTEC develops the Multi Parallel Technology to produce a carbon fiber reinforced polymer (CFRP) with tailor-made mechanical properties. The Swiss startup manufactures monolithic structures, hollow and sandwich parts in one shot. Advantages include a high stiffness at a low weight, dimensional stability, vibration damping, and x-ray transparency.

- Italian Nano-Tech works on a unique system for introducing nanoparticles into a fluid, obtaining consistent homogeneous dispensers. 3Dynamics, as the process is called, allows the startup to produce advanced materials like low-viscosity nano-engineered epoxy systems, heat-resistant prepreg as well as high electrical conductivity thermoplastic polymers.

- Ubidots creates an internet of things platform enabling the communication and data-sharing of smart factories with engineers in real-time. The startup’s device-agnostic cloud makes it easy to connect hardware and/or digital data services. Thus, predicting equipment failures, sending alerts regarding production and quality errors as well as encouraging operators to keep pace with dashboard display. In short, Ubidots supports asset monitoring, maintenance, automation, energy management, and supply chain optimization.

- Simularge works on leveraging simulation tools for the mechanical engineering industry. The company develops a collaborative platform and 3D computation tools that enable engineers to predict the strength & quality of machine parts/systems prior to their production. Simularge’s tools facilitate the virtual testing of parts in a fast and collaborative manner to meet the desired specifications painlessly.

- DecisionIQ develops the artificial intelligence platform Genesis AI which incorporates machine learning and a prescriptive maintenance engine to solve the issue of how to react to a machine failure by recommending the cost-optimal repair planning.

Explore Emerging Manufacturing Startups & Technologies

While these cutting-edge startups and technologies all make their mark on the manufacturing industry, there is a wide variety of innovation areas and emerging companies yet to be discovered. For manufacturers aiming to stay on top of their competitors, technologies such as automation, optimization, cloudification as well as biomechanics present an additional chance to intensify their innovation efforts.