The manufacturing sector is undergoing a transformative shift, driven by the need to reduce carbon emissions and integrate AI into production processes. Robotics and automation boost efficiency while addressing labor shortages, data analytics improve supply chain forecasting, and IoT enhances connectivity and real-time monitoring. Other key trends shaping the industry include additive manufacturing, industrial automation, and sustainable practices. Additionally, the integration of edge computing, 5G, and advanced cybersecurity solutions is becoming critical for modern production lines. This data-driven report highlights emerging manufacturing trends and innovations for 2025 & beyond.

What are the Top Manufacturing Trends in 2025?

- Additive Manufacturing

- Industrial Automation

- Sustainable Manufacturing

- Supply Chain Analytics

- Nanotechnology

- Edge Computing

- Cobots

- 5G

- CyberSecurity

- Digital Twin

Innovation Map outlines the Top 10 Manufacturing Trends & 20 Promising Startups

For this in-depth research on the Top Manufacturing Trends & Startups, we analyzed a sample of 11424 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the manufacturing industry. In the Manufacturing Industry Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

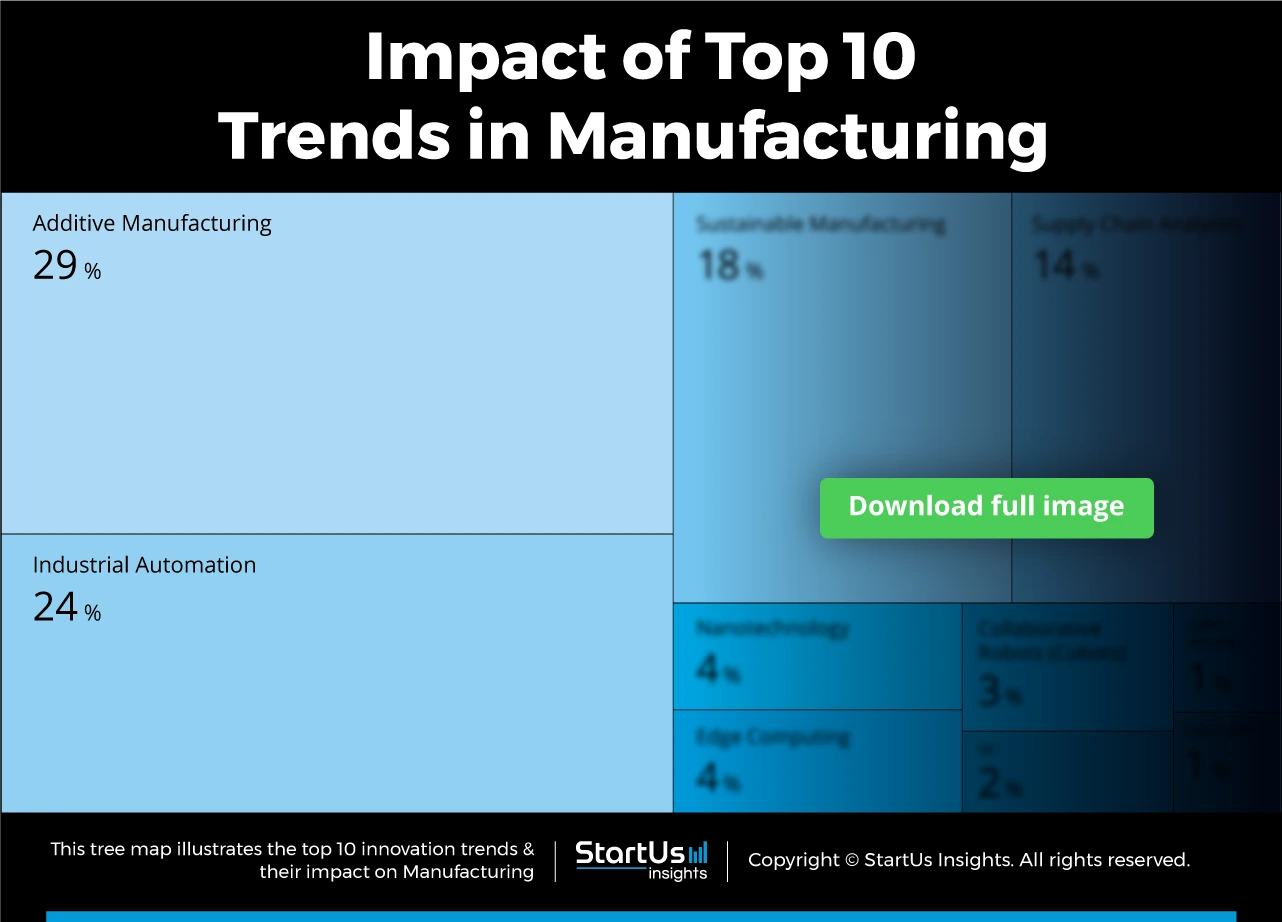

Tree Map reveals the Impact of the Top 10 current Trends in Manufacturing (2025)

The TreeMap below illustrates the impact of the Top 10 Manufacturing Industry Trends in 2025. The industry is shifting towards digital and sustainable practices by adopting renewable energy, minimizing waste, and incorporating circular economy principles through material recycling and extended product lifecycles.

Startups and scaleups are developing solutions that use AI to monitor, optimize, and secure supply chains. Additive manufacturing allows for faster production of complex components at reduced costs. The integration of AI, IoT, and big data enhances connectivity within production facilities, improving efficiency, flexibility, and product customization.

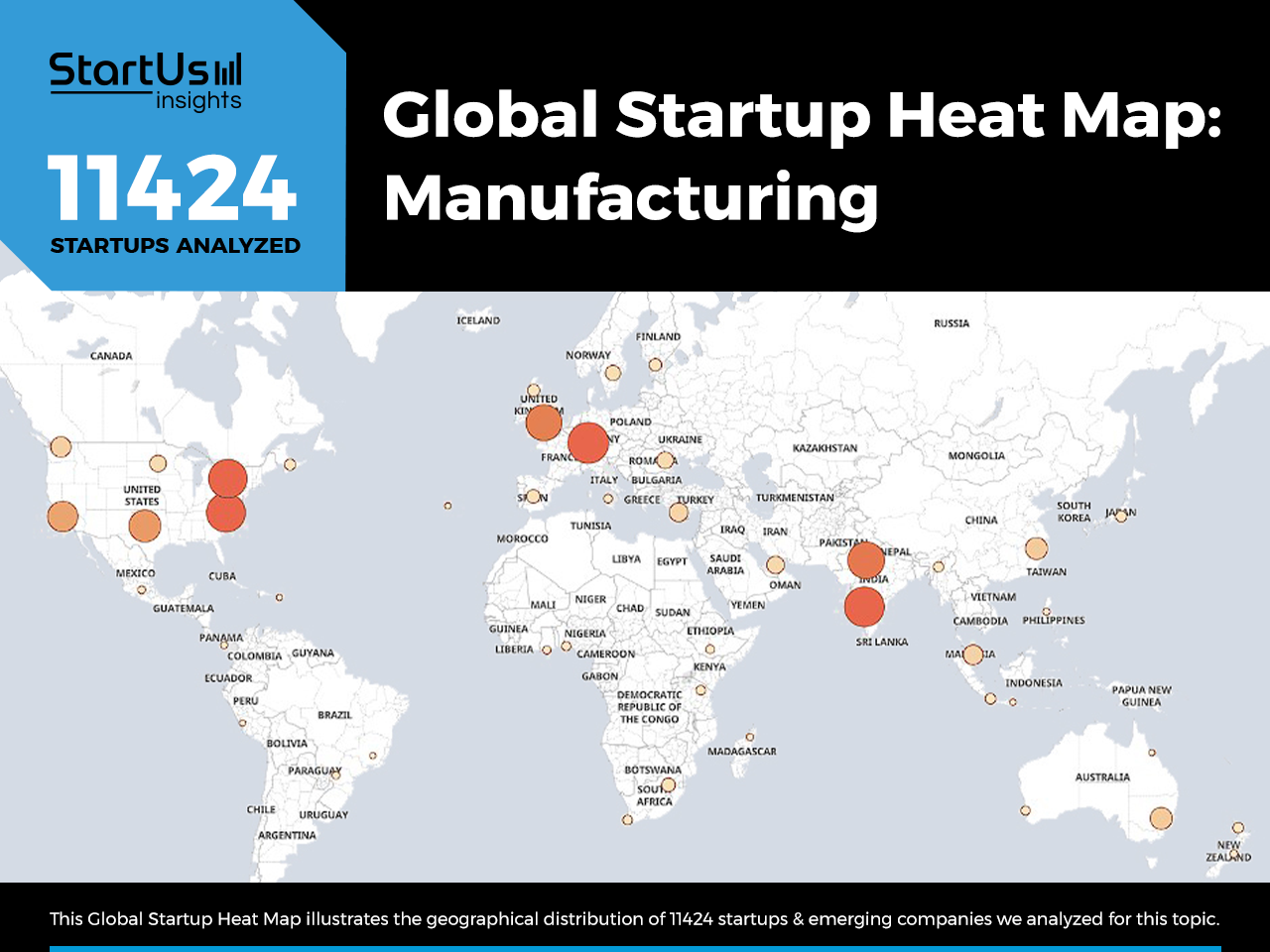

Global Startup Heat Map covers 11424 Manufacturing Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 11424 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals high startup activity in Western Europe and the US, followed by India.

Below, you get to meet 20 out of these 11424 promising startups & scaleups as well as the solutions they develop. These manufacturing technology startups are hand-picked based on criteria such as founding year, location, funding raised & more. Depending on your specific needs, your top picks might look entirely different.

Want to explore all manufacturing innovations & trends?

Top 10 Manufacturing Industry Trends in 2025

1. Additive Manufacturing

Additive Manufacturing or 3D printing facilitates the production of complex geometries that are often impossible with traditional methods while reducing the need for expensive tooling and molds. This allows for rapid prototyping and faster design iterations, shortening development cycles. Materials like polymers, metals, ceramics, and composites, increase printing efficiency. For example, Airbus uses (DMLS) direct metal laser sintering to manufacture structural components and interior parts. This contributes to reduced weight and improved fuel efficiency. Industrial 3D printing also reduces material waste and enables local production.

FORG3D provides 3D Printed Castings & Forgings

FORG3D is a UK-based 3D printing startup that uses direct energy deposition (DED) and wire arc additive manufacturing (WAAM) techniques to print metal structures. It allows manufacturers to leverage design flexibility and rapid prototyping, allowing for the efficient production of complex geometries. The company thus offers a greener and faster alternative to castings and forgings.

ADDIMETAL offers Binder Jetting-based Metal Parts Production

French startup ADDIMETAL utilizes a binder jet printing process for manufacturing complex geometries with different materials. The company’s technology reduces material waste, lowers production costs, and consumes less energy. Their large format and capacity industrial print head enable the optimization of the use of the six-liter job box. This allows manufacturers to streamline metal part prototyping and production.

2. Industrial Automation

Industrial automation enables higher precision, speed, and scalability by integrating advanced robotics, AI, and machine learning into production processes. Automated systems replace manual tasks, reducing variability and human error while enabling real-time adjustments through predictive maintenance and monitoring. This shift towards smart manufacturing integrates industrial IoT (IIoT), connecting machines, sensors, and control systems to create a responsive, data-driven production line. By automating tasks such as assembly, material handling, and quality control, manufacturers reduce downtime, increase throughput, and maintain cost-effectiveness, even in high-mix, low-volume production environments where flexibility is essential.

Pivot Robotics automates High-Mix Manufacturing

US-based startup Pivot Robotics develops robotic systems for high-mix manufacturing. The startup combines off-the-shelf robots and vision sensors with proprietary vision control software. This way, the robots adapt to working conditions without large data requirements. The startup uses vision technology to develop hand-eye coordination for robot arms, enabling the automation of tasks beyond grinding, like materials handling and assembly for high-mix manufacturers.

Terafac develops an AI-Vision Platform for Welding

Indian startup Terafac offers an AI and Vision platform that enables robots to autonomously scan, position, and weld. The platform integrates machine vision with AI-driven algorithms to identify and adapt to complex welding tasks in real-time. Automating scanning and positioning ensures precise and consistent welds without manual intervention. This reduces downtime, increases operational efficiency, and enhances overall production quality.

3. Sustainable Manufacturing

Sustainable manufacturing integrates advanced technologies and processes to minimize environmental impact while maximizing production efficiency. Companies leverage energy-efficient systems, closed-loop production, and renewable energy sources such as solar and wind to reduce resource consumption and emissions. A critical component is the adoption of green materials, which include bio-based polymers, recycled metals, and eco-friendly composites that are engineered for recyclability and biodegradability. By utilizing these materials alongside innovations like digital twins and smart manufacturing systems, companies reduce waste, improve resource efficiency, and meet stringent environmental regulations.

Bloom Labs manufactures Fibers from Natural Waste

Bloom Labs is a startup from the US that manufactures natural waste-based fibers. The startup leverages bio-manufacturing, protein engineering, and molecular biology to regenerate waste into pellets. These pellets are integrated with the manufacturer’s production process, as a scalable raw material without the feedstock risks or environmental impact of petroleum. In this way, Bloom Labs accelerates the circular economy by recycling synthetic fibers and plastics.

Cyclezyme offers Virgin Raw Material Alternative

Cyclezyme is a Swedish startup that develops an enzymatic platform that breaks down PET-based plastic materials into new building blocks, eliminating the need for solvents and high temperatures. The platform makes use of careful experiments and analyzes how different enzymes behave in the breakdown of plastic material. The company’s approach contributes to a circular plastic economy by reducing plastic waste and promoting the reuse of plastic. This ultimately decreases the reliance on virgin raw materials and fossil fuels for manufacturing. The platform combines experimental data and data analysis techniques to refine enzymes and optimize the plastic recycling process.

4. Supply Chain Analytics

Supply chain analytics facilitates the manufacturing industry by optimizing operational efficiency and assisting in decision-making. By leveraging real-time data and predictive models, manufacturers improve demand forecasting to reduce stockouts and overproduction. For instance, Siemens integrated supply chain analytics to streamline inventory management. This resulted in significant cost savings and improved production scheduling. Using these data points, manufacturers also improve supplier relationships and ensure timely delivery of raw materials. Advanced analytics supports risk management by predicting potential disruptions and allowing for proactive contingency planning. This data-driven approach allows manufacturing firms to respond swiftly to market changes and maintain competitiveness.

Intelichain designs a Demand Planning Software

Israeli startup Intelichain provides an AI-driven demand planning platform designed to eliminate inventory and sales losses through predictive planning. The platform leverages AI algorithms and machine learning techniques to analyze historical data, detect demand patterns, and generate precise inventory forecasts. This approach optimizes the business supply chain performance, balancing inventory levels with market demand preventing overproduction and stockouts. The company’s technology streamlines the Sales & Operations Planning (S&OP) process, ensuring data-driven decisions without the need for manual interventions.

Quantics boosts AI-Driven Production Planning

Austrian startup Quantics develops AI-powered supply chain analytics solutions to help manufacturing companies optimize their operations in volatile and complex environments. The company’s platform integrates real-time data analytics and demand forecasting, allowing manufacturers to manage inventory, forecast demand, and plan production more accurately and efficiently allocate resources. It enables manufacturers to dynamically adjust their supply chains, ensuring optimal inventory levels, better decision-making, and reducing inefficiencies. The company’s analytics tools adapt to each client’s unique supply chain structure, ensuring tailored insights that drive tangible improvements in efficiency and predictive analytics.

5. Nanotechnology

Nanotechnology enables the creation of materials and processes at the nanoscale, resulting in enhanced performance and functionality. For example, nanomaterials such as carbon nanotubes and nanocomposites improve the strength, durability, and thermal resistance of products while reducing weight and material usage. Manipulation of materials at the atomic level leads to nanomaterials that are stronger, lighter, and more corrosion-resistant, improving product lifespan and performance. These materials advance manufacturing processes through precise control of material properties and the development of self-cleaning surfaces. Additionally, nanotechnology enables the development of heat-resistant coatings and materials for industries where extreme temperatures are a challenge.

NGNT develops Advanced Nanotechnology Coating

Swiss startup NGNT develops a nano-coating product that provides advanced protection for a wide range of industrial applications. The company’s coating product combines nanodiamonds with perhydropolysilazane (PHPS), creating a highly durable and elastic surface that resists scratches, corrosion, UV radiation, chemicals, and extreme temperatures. They specialize in mixing chemicals and developing composite materials that are hydrophobic, lightweight, strong, and offer good anti-abrasion characteristics. It enables nanotechnology to offer improved properties to products like glass, ceramic tiles, acoustics, and food packaging.

VERDE Nanomaterials offers Sustainable Cellulose Nanofibers

US-based startup VERDE Nanomaterials enables the production of cellulose nanofibers from undervalued waste feedstocks, such as agricultural residues and industrial hemp. The company’s conversion technology employs a proprietary chemical-mechanical process that operates under mild conditions, avoiding the use of toxic chemicals and relying on off-the-shelf equipment commonly found in industries like pulp and paper. The process parameters are tunable to specific customer needs and the company aims to scale this process in a cost-competitive manner.

6. Edge Computing

Edge computing allows data to be processed at or near the source of generation, which is crucial in manufacturing environments. This proximity reduces latency, enabling real-time analytics and decision-making. Manufacturers adjust production parameters, optimize resource allocation, and respond to quality issues as they arise, leading to improved operational agility and efficiency. For instance, in predictive maintenance, edge computing facilitates the integration of smart sensors within machinery, which continuously monitor equipment health and performance. Edge computing supports robotics and automation systems, which require rapid data processing to improve precision and responsiveness in production tasks. It works with Internet of Things (IoT) devices used in manufacturing. It handles the data generated by numerous IoT sensors and devices, facilitating better coordination and control across various aspects of the production process.

Basic Networx offers Smart Factory Network Solutions

US-based startup Basic Networx provides modular edge computing solutions designed for advanced industrial IoT setups. It combines multi-WAN technologies, including LTE modems and broadband connections. This enables flexible, reliable networking across fixed, mobile, and tactical environments such as manufacturing facilities. The company integrates seamlessly with cloud services such as AWS IoT Core and Kinesis, processing and transmitting data from wired and wireless sensors. Its key offering, the BNX-2000 Series, delivers comprehensive functionalities at competitive pricing, drastically reducing the total cost of ownership.

Weeteq enhances Manufacturing Asset Predictive Maintenance

UK-based startup Weeteq offers Ultraedge, a proprietary edge computing technology that performs real-time analysis and detects anomalies directly within the circuit. This technology enables immediate, unsupervised performance optimization of manufacturing assets without data training. Ultra Edge generates critical operational data that integrates into system-level platforms and digital twins which improves the performance of the manufacturing assets. Another product Dynamic Digital Shadow provides accurate replication of the facility in real-time to derive insights while it offers other companies to integrate their technology through products like Ultra Edge Silicon, Ultra Edge Circuits & Modules.

7. Cobots

Unlike traditional industrial robots, cobots work alongside human operators without requiring extensive safety barriers, which facilitates more flexible and efficient workflows. Cobots reduce implementation costs and make automation accessible to smaller manufacturers. For example, they provide precision and consistency in welding tasks, which is beneficial for companies facing a shortage of skilled welders. Cobots excel in repetitive tasks like palletizing and machine tending, which reduces physical strain on employees and minimizes errors associated with manual labor. Equipped with advanced sensors, cobots detect the presence of humans and adjust their movements to prevent accidents. Cobots are programmable and reconfigurable for different tasks, making them adaptable to changing production requirements.

MZ Robotics makes Palletization & Deburring Cobots

Italian startup MZ Robotics designs customized cobot solutions that are easy to program, fast to implement, and safe to use. The company’s cobots feature intuitive programming interfaces, which streamline integration into existing workflows and reduce setup times. These cobots perform various operations like palletization, deburring, sanding, painting, and framework.

VanMade provides Customizable Manufacturing Cobots

Dutch startup Van Made develops custom automated systems, focusing on integrating cobots into manufacturing operations. The company designs cobots to perform tasks such as product handling, packaging, palletizing, and processing, enhancing automation across various production stages. Van Made continuously advances cobot capabilities, developing plug-and-play solutions that are added into a facility with little adjustments.

8. 5G

The integration of 5G allows for enhanced data collection from numerous sensors and devices on the factory floor. This capability supports the monitoring of critical metrics such as temperature, vibration, and throughput, facilitating early detection of issues and proactive maintenance. 5G is a key enabler of Industry 4.0, facilitating the implementation of smart manufacturing technologies such as IoT devices, robotics, and artificial intelligence. For example, 5G facilitates the integration of automated systems and real-time monitoring of production lines. Thus, reducing downtime and increasing throughput. This technology addresses the challenge of managing large data volumes by delivering high bandwidth and low latency for timely data analysis.

Shadobi develops Network-Aware Manufacturing Apps

Canadian startup Shadobi’s NetAware allows manufacturers to enhance Industry 4.0 operations by enabling network-aware applications that manage network resources across 4G, 5G, and Wi-Fi 6. This ensures high-speed, low-latency connectivity for critical processes like AI-driven automation and real-time decision-making. NetAware’s APIs allow developers to create applications that optimize network performance, supporting advanced use cases such as large-scale automation, VR/AR-assisted operations, and automated quality control. Thus, by integrating NetAware, manufacturers improve connectivity and ensure smooth, efficient operations in connected factory environments.

Tidal Wave enables Remote Equipment Monitoring & Control

Indian startup Tidal Wave offers software-defined network controllers and virtualized network functions (VNFs), designed to deliver high-bandwidth and low-latency connectivity. These solutions support critical applications such as real-time sensor data processing, autonomous systems, and robotics operations. These networks enable real-time data collection and analysis, as well as remote monitoring and control of machines and equipment, improving overall productivity and reducing waste and inefficiency in the manufacturing process. The company’s VNFs support specific requirements of private 5G networks in airports, as well as advanced security and quality of service (QoS) features.

9. Cybersecurity

Cybersecurity impacts the manufacturing industry by safeguarding digital assets and ensuring operational continuity. As manufacturing processes become increasingly connected through IoT and digital platforms, they face challenges such as vulnerability to cyberattacks, data breaches, and operational disruptions. Technologies such as intrusion detection systems (IDS) and intrusion prevention systems (IPS) enhance threat detection and response, while network segmentation isolates critical systems to limit the impact of potential breaches.

Advanced encryption techniques protect sensitive data, and secure access controls prevent unauthorized entry into industrial control systems. For instance, cybersecurity measures prevent ransomware attacks that cripple production lines and disrupt supply chains. Implementation of endpoint protection and regular security updates fortify systems against evolving threats. By integrating these technologies, manufacturers manage risks related to operational technology (OT), reduce downtime, protect intellectual property, and maintain consistent production efficiency.

Sentinel Devices provides Equipment Anomaly Detection

US-based startup Sentinel Devices develops OTAware, a machine learning-based platform that continuously monitors manufacturing equipment and provides real-time alerts for potential issues. The technology works by capturing and retaining all operational data, allowing seamless transition when parts are upgraded or replaced. The company’s Blame Support feature uses correlations learned from machine data to show the teams exactly which signals are most out-of-line. It also enables an instant assessment of what needs to be treated first. The product’s unique features include its local processing, eliminating the need for internet connectivity, and its compatibility with major industrial protocols, enhancing cybersecurity and reducing downtime.

Cervais enables Critical Asset Protection

US-based startup Cervais utilizes its SG-X Gateway and Cylenium Cloud to provide manufacturing companies with data-driven optimization and advanced cybersecurity. The platform leverages IoT sensors and machine learning algorithms to collect and analyze real-time manufacturing equipment data. Thus, enabling predictive maintenance, reducing downtime, and enhancing overall equipment effectiveness (OEE). The SG-X Gateway ensures secure supply chain visibility through AI-driven monitoring, identifying security risks and anomalies in real-time. It also provides secure remote access with encrypted data and multi-factor authentication, safeguarding critical processes and intellectual property. This integrated solution optimizes production efficiency while fortifying cybersecurity, ensuring compliance with industry regulations.

10. Digital Twin

Digital twins impact the manufacturing industry by providing virtual replicas of physical assets and processes, enabling detailed simulation and analysis. These digital models facilitate real-time monitoring and predictive maintenance, addressing challenges such as equipment failures and production inefficiencies. For example, digital twins enable manufacturers to simulate the impact of changes in production parameters on a virtual model before implementing them on the shop floor, reducing the risk of costly disruptions. They allow for real-time tracking of machinery conditions, predict maintenance needs, and minimize unplanned downtime. By integrating digital twins with IoT and AI technologies, manufacturers enhance process control, improve decision-making, and achieve greater operational efficiency. Thus, leading to increased productivity and reduced costs.

Aleph Tech offers Virtual Replicas of Production Processes

Singaporean startup Aleph Tech leverages digital twin technology and AI to create virtual replicas of complex industrial processes like chemical and physical reactions, to generate real-time insights for optimization. The AI Co-Pilot automates root cause analysis and recommends operational setpoints to enhance regular processes. The company’s no-code platform simplifies troubleshooting, process optimization, and simulation by implementing operation set points that enhance manufacturing operations. These operational settings enhance energy efficiency, improve product quality, and maximize yield through an AI-driven platform.

MultiAI deploys Digital Twins for Contested Logistics

US-based startup MultiAI provides an agent-based digital twin platform that integrates real-time data from various sources to offer a unified, dynamic model of the entire supply chain. Its platform uses AI-enhanced simulations to visualize and analyze day-to-day operations. This enables users to anticipate and mitigate disturbances like port delays and bad weather. Unique features include the ability to run thousands of “what-if” scenarios for optimizing master plans related to manufacturing, inventory, and transportation. The platform enables cross-departmental collaboration through the integration of internal and external data. This solution enhances supply chain visibility and supports faster decision-making to prevent disruptions and streamline manufacturing operations.

Discover all Future Trends in Manufacturing

The trends mentioned in this article improve production efficiency and address the communication gap between workers. Additive Manufacturing generates various possibilities of intricate design with less lead time previously not achievable by traditional manufacturing.

Edge Computing devices and platforms offer real-time insights about the shop floor, improving the decision-making for higher management. Nanotechnology fosters lightweight materials, enhancing their properties and product performance with minimal defects. Digital Twins manages the entire lifecycle of assets, improving longevity and reducing cost. These trends together modify manufacturing practices, promoting growth, cost-effectiveness, and eco-friendly practices.

The Manufacturing Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.