The growing demand for electronic devices and other technological innovations is driving the need for virgin raw materials like silicon and other exotic metals. At the same time, there is a push toward lowering the environmental impact of mining activities. To address these issues, startups and scaleups pursue innovations that enhance the efficiency, economic viability, and sustainability of mining operations. This report provides an overview of mining trends ranging from connected mines and artificial intelligence (AI) to sustainable operations and 3D printing. Read more to explore how they impact your businesses.

Innovation Map outlines the Top 8 Mining Trends & 16 Promising Startups

For this in-depth research on the Top Mining Trends & Startups, we analyzed a sample of 1 759 global startups and scaleups. The result of this research is data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups in the mining industry. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2 500 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant startups, emerging technologies & future industry trends quickly & exhaustively.

In the Innovation Map below, you get an overview of the Top 8 Mining Trends & Innovations that impact 1 759 companies worldwide. Moreover, the Mining Innovation Map reveals 16 hand-picked startups, all working on emerging technologies that advance their field.

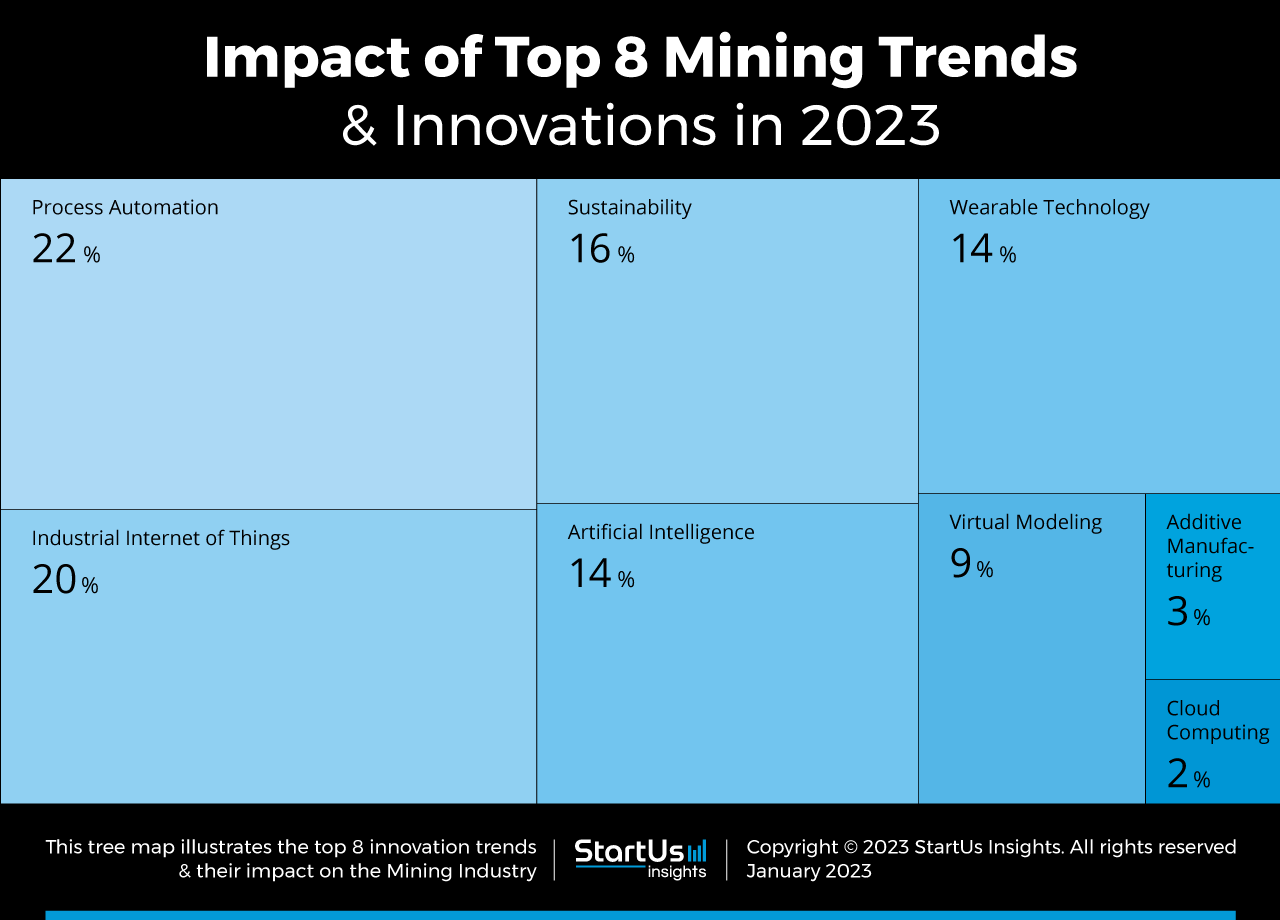

Tree Map reveals the Impact of the Top 8 Mining Trends

Based on the Mining Innovation Map, the Treemap below illustrates the impact of the top 8 Mining Trends in 2023. The major innovations focus on the implementation of autonomous or remotely-controlled systems. Advances in sensors and other probing technologies lead to the adoption of the industrial internet of things (IIoT). Mining companies use IIoT to track processes and assets to improve productivity. The threat of climate change calls for more sustainable mine operations through electrification and zero-waste mining technologies. Further, AI, wearable devices, virtual modeling, and cloud computing aids in handling operational data. This, in turn, provides insights that aid in reducing operational costs and enhancing mine safety and efficiency. Lastly, additive manufacturing streamlines the development and manufacturing of custom and spare parts with minimum lead time.

Top 8 Mining Trends

- Process Automation

- Industrial Internet of Things

- Sustainability

- Artificial Intelligence

- Wearable Technology

- Virtual Modeling

- Additive Manufacturing

- Cloud Computing

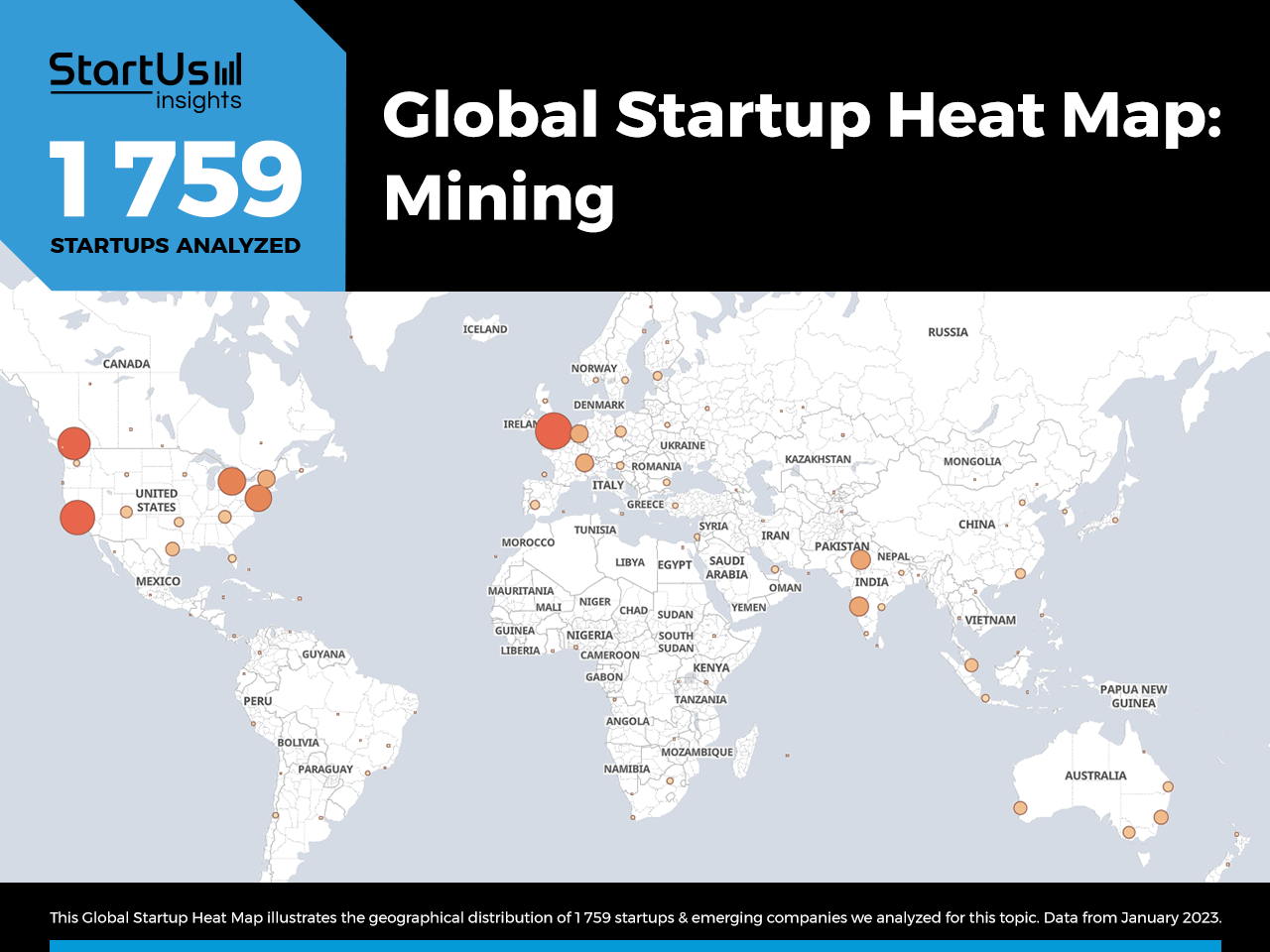

Global Startup Heat Map covers 1 759 Mining Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 1 759 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that UK and US see the most startup activity.

Below, you get to meet 16 out of these 1 759 promising startups & scaleups as well as the solutions they develop. These 16 startups are hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 8 Mining Trends in 2023

1. Process Automation

Mining operations like excavation, material handling, and site inspections are complex and labor-intensive. The increasing demand for metals and minerals thus necessitates the deployment of additional machines and workers. Advances in robotics and associated AI allow autonomous or remote mine operations. This enables the human-free operation of drills through the automation of electric trains to carry ore to dump trucks, which follow a prescribed path to the processing facility. Moreover, process automation reduces the need for recruiting new employees and eliminates human presence in hazardous environments, improving worker safety.

Arventek delivers Mine Inspection Automation

Turkish startup Arventek develops autonomous unmanned aerial vehicles (UAVs) that capture geographic visual data and analyze mine activities. The startup’s UAVs feature vertical take-off and landing (VTOL), thereby minimizing space requirements and improving maneuverability. Arventek’s platform, RemoteSite, plans the inspection routes, examines the details, and tracks flight through live flight simulation. The UAVs capture high-resolution photos and transform them into digital maps and 3D models. They provide insights to speed up decision-making on mine expansion, inventory, and safety as well as enable remote asset management for mine managers.

SafeAI enables Autonomous Mining

SafeAI is a US-based startup that offers retrofit solutions to convert mining vehicles into self-driving assets. The startup’s sensor suite, along with AI-powered autonomous software, manages and operates vehicles autonomously in mines. It features a perception system that dynamically maps the environment and detects and reacts to obstacles in real-time. SafeAI’s vehicle-agnostic system thus enables easy integration to workflows and creates safer, zero-entry worksites with higher productivity and reduced operational costs.

2. Industrial Internet of Things

Digital sensors and smart devices are ubiquitous in work environments, but the vastness of mining sites makes it difficult to access the captured data. This creates data silos that undermine the utility of sensor data, and create inefficiencies. Leveraging IIoT provides global access to operational data to stakeholders from mine operators to top management. Further innovations allow for real-time condition monitoring of mining equipment, smart measurements, and remote operations that improve operational efficiency and resource utilization.

SedimentIQ aids Mine Equipment Tracking

US-based startup SedimentIQ provides an IIoT platform that tracks equipment utilization. The startup utilizes off-the-shelf devices like smartphones and Bluetooth beacons to capture data on equipment operations. Its platform tracks and measures this data and automatically analyzes it to generate insights regarding under-utilized machines. This allows mine engineers and managers to easily identify cycle times and improve asset utilization.

Datacakra enables Environment Monitoring

Datacakra is an Indonesian startup that specializes in IIoT and monitoring systems. The startup’s IIoT platform, Provisense, handles heavy-duty enterprise-grade IoT solutions supporting a wide range of industrial sensors. Datacakra’s other solution, Smartpole, converts existing light poles into smart devices. They monitor the mine environment, weather, pollution levels, and hauling truck speed, allowing mine managers to remotely monitor mine conditions.

3. Sustainability

Mining is energy and resource-intensive process, generating a significant carbon footprint. The threat of climate change and scarcity of natural resources necessitates sustainable and cleaner mining technologies for the industry’s future. Further, mining companies are to achieve various sustainability goals set by governments, making it hard to address the increasing demand for minerals and metals. That is why startups and scaleups develop solutions that reduce the environmental impact due to mining activities. They include alternate fuels, asset electrification, as well as reduced material consumption, and waste generation. These solutions allow mining companies to keep up with the demands of growing economies with minimal environmental impact.

Genomines advances Plant-based Metal Extraction

Genomines is a French biotech startup that enhances plants’ natural biology to renewably mine nickel. The startup’s genetically engineered metal hyperaccumulator plants produce bio-sourced metals. These genetic modifications improve these plants’ ability to efficiently and economically extract metals while simultaneously remediating the land. Genomines’ technology makes it also possible to extract metals from mine tailings. This enables clean mining and allows mining companies to remove traces of toxic heavy metals from the soil.

Lekatech simplifies Mining Equipment Electrification

Finnish startup Lekatech is a mining and construction tech startup that electrifies drilling and hammering equipment. The startup’s linear motor technology transforms conventional hydraulic carrier machines into electric assets. These electric hammers offer higher performance than conventional equipment with precise control over every blow and gap while reducing carbon emissions.

4. Artificial Intelligence

The digitalization of mining operations creates data streams that aid mine engineers and managers to assess operations in real-time. AI adds a new dimension to data analytics wherein the identification of trends or patterns multiplies data utility. Startups leverage machine learning (ML), deep learning (DL), and natural language processing (NLP) to provide insights into mining operations. They enable pattern and trend identification to advance anomaly detection, predictive maintenance, and digital twins for mining operations. This way, artificial intelligence allows business stakeholders to make quick and informed decisions while automating operations.

Optecs provides Operational Analytics

Optecs is a Dutch startup that offers an AI-based decision-making solution for mining measurement and control systems. The startup’s solution, Smart Mill Control System (SMCS), uses dynamic modeling and combines with the programmable logic control (PLC) system to collect operational data. It then analyzes the data and provides control strategies to achieve optimum operation. This allows mine operators to reduce wear and downtime as well as lower specific power and water consumption while increasing throughput.

Cognecto ensures Optimum Asset Utilization

Cognecto is an Indian startup that provides an equipment monitoring solution for heavy mining equipment. The startup’s AI-powered edge device collects sensor data from multiple sources and transfers it to the cloud. Cognecto’s solution then analyses the data and provides insights into real-time asset utilization. This enables on-field diagnostics and improves heavy equipment life.

5. Wearable Technology

Mines employ a large number of workers, and businesses need to ensure that they are properly trained, safe, and healthy. Wearable technologies like augmented reality (AR), virtual reality (VR), and extended reality (XR) offer training and guidance that allow new hires to train without exposure to hazardous situations. Other wearable devices, such as IoT-enabled helmets, vests, and wrist bands, track operator movements, monitor their vital signs, and detect safety incidents. Wearables thus allow mining companies to monitor employee expertise and ensure their well-being.

Metasense aids Environmental Risk Management

Australian startup Metasense provides SafeSpot, a modular wearable device for environmental risk management. It fits onto safety helmets to track and implement employee safety measures. Metasense’s combined hardware, software, and cloud collect data for record management, provide real-time operational visibility, and inform downstream decisions. This allows mine managers to remotely track employee movements and monitor their environments to identify safety risks and unwanted activities.

36Zero creates Connected Mines

UK-based startup 36Zero offers a smart band that continuously monitors worker location and vital signs. It tracks work locations to keep them in safe zones and identifies unauthorized activities and lone workers. The smart band also features a panic button to notify when help is required whereas its vital sign monitoring enables proactive and preventative actions during physical distress. Further, it allows safety officers to push urgent messages and evacuation alarms, making mining environments safer, healthier, and smarter.

6. Virtual Modeling

Innovations in virtual modeling aid in the development of 3D visualization and digital mapping solutions. They enable the creation of digital models that improve visibility into mine operations. Virtual modeling solutions utilize AI algorithms to convert asset images into 3D models that describe mine asset location and condition. This provides mining engineers and managers with insightful data that facilitates inspection scheduling and maintenance planning. Consequently, virtual modeling improves asset and mine monitoring, ensuring safety and high throughput.

gNext Labs creates Digital Maps

US-based startup gNext Labs uses data analytics to convert video and image data into actionable business and operational intelligence. The startup’s proprietary cloud-based software-as-a-service (SaaS) solution creates highly accurate point cloud and 3D models of mining sites. These models enable miner managers to improve inventory management, measure reserve consumption, track mining progress, and assess site safety.

Headlight AI enables Underground Mine Investigations

UK-based startup Headlight AI offers a light detection and ranging (LiDAR) and imaging solution for underground mine inspection and mapping. The solution uses a 360-degree spinning scanner that continually captures images of assets and equipment. The startup’s software, Telesto, then leverages AI algorithms to identify patterns and features from the images. The AI algorithms further detect and locate hazards to workers in underground mines, allowing businesses to ensure efficient operations. Additionally, the solution provides georeferenced 3D maps for the investigation of new mines.

7. Additive Manufacturing

Mining assets and equipment are highly specific to each mine site and each machine component consumes a huge amount of material and manufacturing resources. This puts a cap on the manufacturing capabilities related to mining components, which in turn increases the lead time for any spare part requirements. Advances in additive manufacturing enable custom manufacturing of parts with sudden requirements with minimal lead time. 3D printing also eliminates the cost-intensive transport of parts to remote sites in the event of equipment failure by using on-site production. Further, it increases operational productivity by reducing machine downtimes.

hyperTunnel simplifies Underground Constructions

hyperTunnel is a UK-based startup that offers cast mining and 3D printing techniques to build tunnels and underground infrastructure for mining activities. The startup uses semi-autonomous robots controlled by AI and machine learning to construct mining structures additively. It also creates a robot swarm that performs tasks from geological inspections, drilling, filling, and other construction activities. This increases construction speed, lowers project risk, removes the uncertainty of the underground path, and reduces material wastage.

WAAM3D offers On-demand Parts Manufacturing

UK-based startup WAAM3D provides wire arc additive manufacturing (WAAM) for the mining sector. The startup’s WAAM machine, RoboWAAM, manufactures at different scales and aids in large-scale metal additive manufacturing to enable on-demand spare part fabrication for heavy equipment. This reduces downtimes for mining operations in cases where part replacement is necessary.

8. Cloud Computing

Digitalization of the mining industry offers access to operational data via IoT devices and platforms. But expanding this access to a location beyond the mining facility requires an extensive computing infrastructure. Cloud computing allows mining companies to leverage data processing and handling capabilities without maintaining expensive IT infrastructure. This reduces capital expenditure and prevents additional operational costs. It also enables remote access to mining data for authenticated users, ensuring seamless communication and mitigating data silos.

GreaseBoss provides Cloud-based Lubrication Monitoring

Australian startup GreaseBoss offers cloud-based software that aids in tracking mine equipment greasing activities. The startup’s equipment data management platform, GreaseCloud, captures and stores greasing data securely. This provides maintenance managers with access to data related to lubrication schedules and grease consumption. The platform further leverages advanced analytics to optimize grease volumes and lubrication intervals.

Minetell aids Workplace Control Monitoring

Canadian startup Minetell offers a cloud-based workplace control monitoring solution that evaluates the performance of health and safety controls. It provides mining companies with secure, real-time information that ensures all control measures work as designed. The solution also offers safety recommendations regarding protective equipment, sanitation, and physical distancing. Lastly, it provides automated alerts that allow safety officers to quickly address areas of concern and reduce exposure to material risks.

Discover all Mining Trends, Technologies & Startups

The future of the mining industry focuses on automation, digitization, and sustainability of processes. Innovations aiding digitalization use technologies like IoT and AI to extract and analyze all available operational data. They enable mining companies to create digital twins of their facilities and improve operational transparency. This also enables continuous process improvement and anomaly detection. Further, technologies facilitating electrification, material repurposing, and zero-waste mining aim to reduce the environmental impact of mining.

The Mining Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation and startup scouting process. Among others, connected mines, AI, and 3D printing will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout startups, technologies & trends that matter to you!