The 2021 Suez Canal obstruction impacted the entire world economy with nearly $10 billion of losses. The incident highlighted both how much the global economy relies on supply chains and, yet, how fragile they are. There have been few macro-scale innovations in the industry in the decade. To boost innovation and make supply chains more resilient, industry leaders are increasingly turning to open innovation in supply chain management.

Why does your Supply Chain need Open Innovation?

Open innovation is a business paradigm where companies seek external innovation to further their innovation needs. By breaking data silos, open innovation accelerates innovation by allowing innovators anywhere to tackle big problems. For the supply chain industry, this also means stronger collaborations among players along a supply chain. First, let’s look at the factors driving the adoption of open supply chain management.

Breaking the Low-cost, Low-margins Cycle

Any costs that add to supply chains impact the cost of virtually everything ranging from petroleum and food to consumer electronics. Because of this, there is an intrinsic limit on how much profits can raise which, in turn, reduces the margins for players in the industry. This leaves little money and resources for industry leaders to innovate. Further, as a few big retailers monopolize the entire length of supply chains, industry leaders cannot compete by innovating in isolation.

Breaking the low-cost, low-margin cycle requires the industry to drastically shift its approach to innovation. Unlike industry leaders, most startups focus on a specific aspect of supply chains. Some of these have the potential to impact the bottom line of supply chains. This is why companies are engaging with startups via open innovation initiatives to optimize their supply chain. On the other hand, transparent data sharing with partners along the value chain further eliminates inefficient operations.

Tackling Resource Constraints

Wastage along supply chains is common across industries. For instance, nearly a third of all food produced is lost along the supply chain. For the transport of non-renewables and other constrained resources, plugging supply chain losses is an utmost priority for the industry. Moreover, these losses contribute to emissions not just in the extra spent fuel but also during waste disposal. Under the traditional model, transporting more was easier than reducing losses beyond a point. However, this is not sustainable in a resource-constrained future.

To tackle these challenges, supply chain operations are increasingly incorporating constraint-based planning. Such a model treats suppliers as partners and requires co-innovation. The Computer giant Dell, for example, works closely with its suppliers. It gathers pain points from them and brainstorms together to come up with solutions.

Shifting toward Reverse Logistics

Earlier, reverse logistics was limited to product recalls and returns. To tackle resource constraints and climate change, there is a greater push toward reverse logistics throughout the supply chain. This is why companies are using open innovation to make their supply chains more circular. Reverse logistics creates additional value for all stakeholders along a supply chain. More importantly, it simplifies and shortens supply chains, reducing waste and costs.

Open innovation models incentivize all stakeholders to collaborate with each other, further optimizing reverse logistics. For example, manufacturers share revenue with other stakeholders or pay retailers to encourage customers to return products at end-of-life.

4 Benefits of Open Innovation in Supply Chains

1. Improves Traceability

Supply chains suffer from a lack of transparency and traceability. Not only does this lead to wastage, but leaves room for malicious players to introduce counterfeit products. Open innovation plugs these gaps by incentivizing stakeholders to work with each other. More recently, innovations like blockchain further improve the efficacy of these collaborations. This way, traceability ensures high product quality while reducing losses.

2. Enables Design for Supply Chain

The shape of soda cans makes it easier to transport them. This is one way where product design is critical to supply chain management. A large number of stakeholders, however, often stall such product design. Open innovation allows manufacturers and suppliers to work together to implement designs for the supply chain.

3. Increases Resilience

As companies grow, they are slower to respond to changes in their environment. Open innovation makes them more agile and, consequently, more resilient to change. Knowledge sharing between manufacturers and retailers makes both parties flexible to supply chain disruptions.

4. Improves Sustainability

Knowledge sharing between stakeholders also facilitates accurate and real-time data reporting. This enables companies to track emissions and take steps to monitor and reduce emissions across their supply chains. Further, innovation keeps supply chains shorter and incentivizes circularity which, in turn, improves sustainability.

Leverage Innovation Intelligence for Supply Chain Management

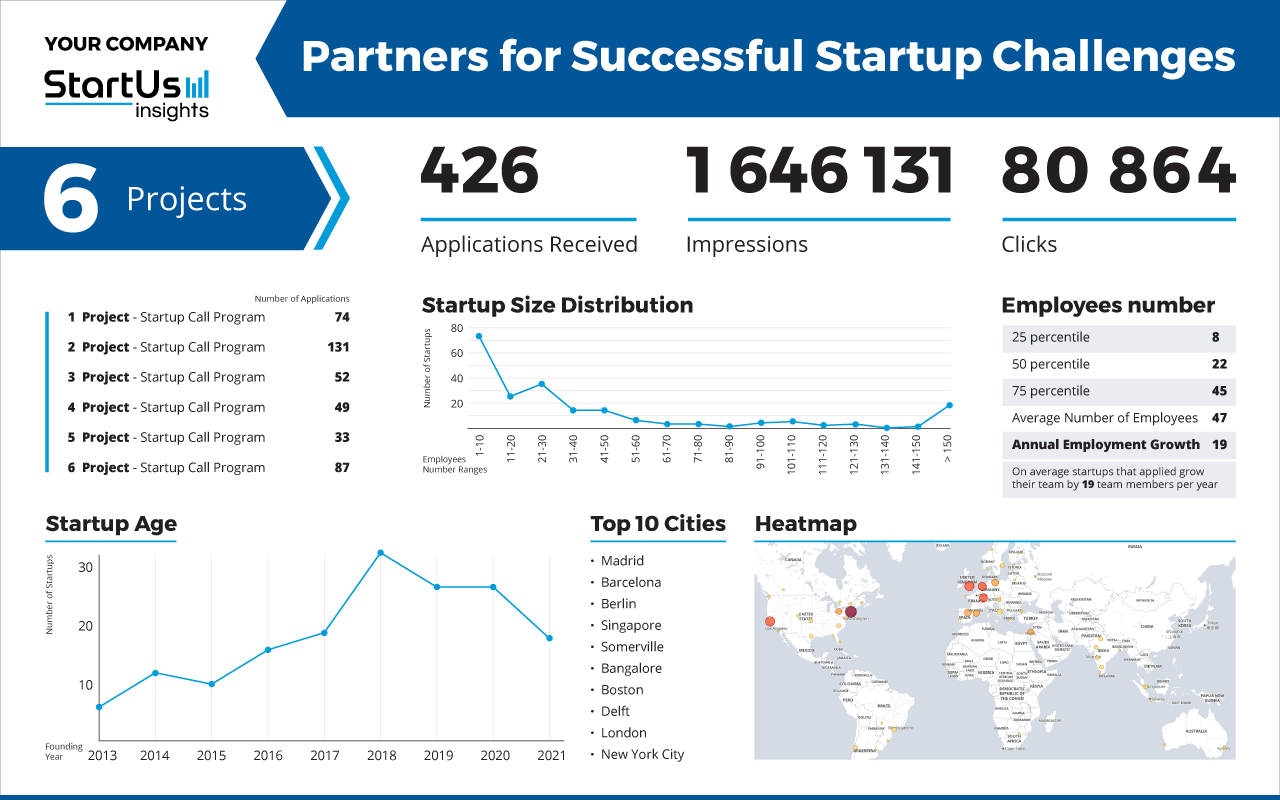

Are you a company looking to bring innovation to your supply chain? Using a data-driven open innovation scouting approach, we at StartUs Insights offer a range of services enabled by our Big Data and AI-powered Discovery Platform, covering over 2,5 million startups & scaleups globally. Some of our services that allow you to leverage external innovation include:

- Startup Programs: Boost startup deal flow through data-driven promotion, direct outreach & storytelling. Reach thousands of startups & scaleups, to attract the most relevant ones.

- Trend Scouting: Identify emerging and latent trends and developments that will impact your company.

- Startup Scouting: Scan over 2,5 M startups & scaleups globally, scouting the right partners for you.

Open innovation allows you to identify the most relevant startups, including vendors and suppliers that share your goals.

![AI Implementation | A Comprehensive Strategic Guide for Enterprises [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/04/AI-Implementation-SharedImg-StartUs-Insights-noresize-420x236.webp)

![AI in Agriculture: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/03/AI-in-Agriculture-SharedImg-StartUs-Insights-noresize-420x236.webp)

![AI in Automotive: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/03/AI-in-Automotive-SharedImg-StartUs-Insights-noresize-420x236.webp)