From 2025 to 2034, the packaging industry is predicted to grow at a compound annual growth rate (CAGR) of 3.16% and reach USD 1.69 trillion by 2034. This is driven by the rising demand for sustainability, manufacturing automation, cost-effectiveness, and regulatory compliance.

This data-driven report explores emerging packaging industry trends, like lightweight, biodegradable packaging, and returnable packaging, as well as the Internet of Packaging (IoP). The article also provides insights into the current status of the market and 20 emerging startups leading the innovations.

What are the Top 10 Packaging Industry Trends in 2025?

- Flexible and Modular Packaging

- Packaging Automation

- Functional Packaging

- Interactive Packaging

- Active Packaging

- Biodegradable Packaging

- Reusable and Returnable Packaging

- Internet of Packaging (IoP)

- Lightweight Packaging

- 3D Printing

Methodology: How We Created the Packaging Industry Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 5M+ global startups, 20K technologies & trends plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative packaging trends in the industry.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the packaging industry innovation ecosystem while highlighting startups driving technological advancements in the industry.

Innovation Map outlines the Top 10 Packaging Industry Trends & 20 Promising Startups

For this in-depth research on the Top 10 Packaging Industry Trends & Startups, we analyzed a sample of 12 480+ global startups & scaleups.

The Packaging Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the packaging industry trends & startups that impact your company.

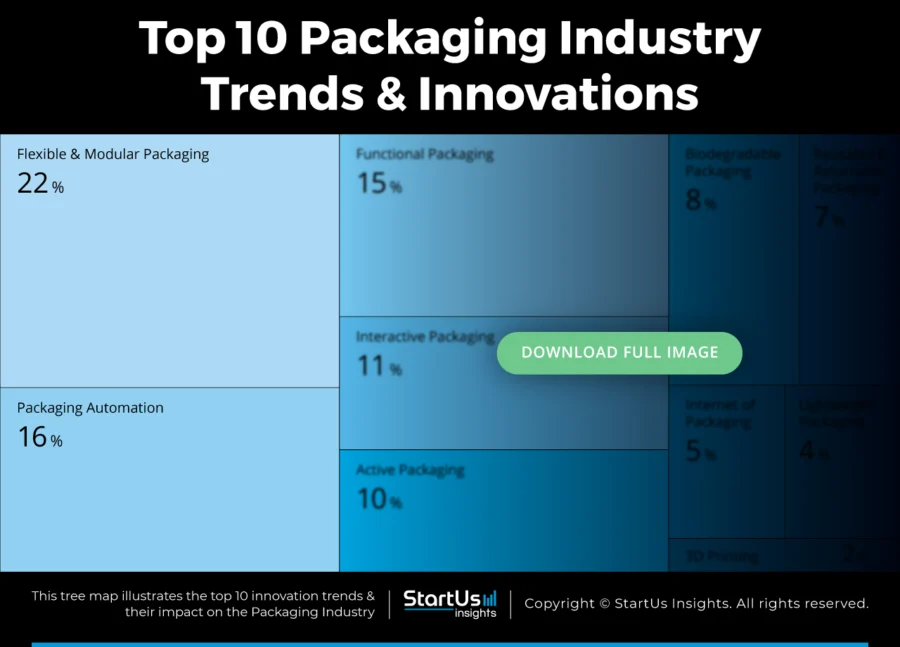

Tree Map reveals the Impact of the Top 10 Packaging Industry Trends

The trends in the packaging industry reveal its alignment with mitigating the climate crisis, improving supply chain efficiency, and improving customer experience. Flexible and modular packaging, lightweight packaging, biodegradable packaging, and reusable packaging are essential for sustainable packaging.

Further, the Internet of Packaging (IoP), packaging automation, interactive packaging, and active packaging reveal the integration of upcoming technologies into the packaging industry.

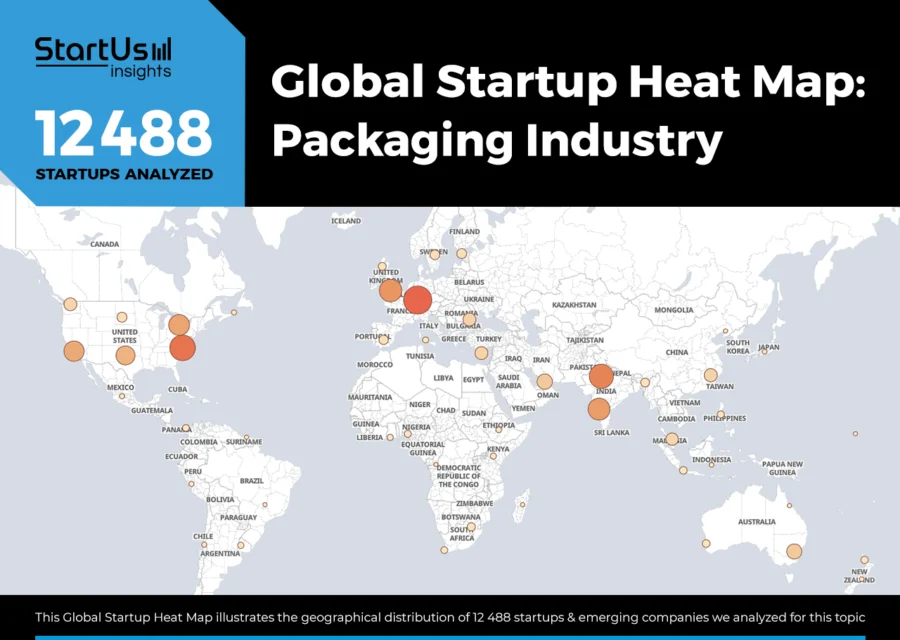

Global Startup Heat Map covers 12 480+ Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 12 480+ exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform.

It highlights high startup activity in the US and India, followed by the UK. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Packaging Innovations & Trends?

Top 10 Emerging Packaging Trends [2025 and Beyond]

1. Flexible and Modular Packaging

Materials like recyclable plastics, mono structures, and compostable films are becoming more prevalent in flexible packaging as they reduce environmental impact. Further, bio-resins are used to make flexible packages.

Several industries including food and beverages, electronics, confectionery, home and personal care, and pharmaceutical use flexible and modular packaging. Their benefits include less waste production and production time, cost-effectiveness, and improved customer experience.

Packages like resealable bags with easy-open closures are further gaining popularity for their convenience and ability to maintain freshness.

For instance, H.B. Fuller has developed Recyclass-certified solvent-based laminating adhesives like Flextra SBA5250 + XA3350. It is a two-component, solvent-based laminating adhesive, which adheres to EU and FDA regulations and is ideal for food safety and retort applications up to 135 degrees Celsius.

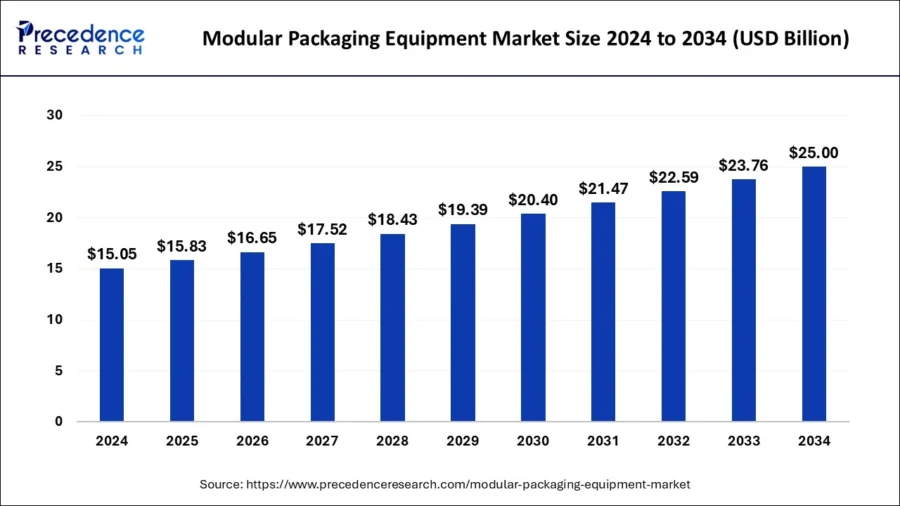

The global modular packaging equipment is expected to exceed USD 25.00 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.21% from 2025 to 2034.

Credit: Precedence Research

LEFMEDPACKS provides Flexible Medical Packaging

Portuguese startup LEFMEDPACKS produces sterilizable medical packaging. The packaging contains solvent or water-based lacquers to provide a fiber-free, fully peelable opening. The coatings are in grid, all-over, or pattern formats and are heat or latex-free cold-sealed.

The packages are flexographic printed with water-based inks. Its production machine also features inline web inspection and enables automatic defect separation at the sitting stage.

Further, the startup employs controlled atmosphere conditions to ensure product and process consistency and automatic mixing systems to ensure coating consistency. It also uses humidity and temperature control, positive air pressure, and separate departments to prevent product contamination.

EvoPak develops Paper-based Flexible Packaging

UK-based startup EvoPak makes recyclable, compostable, and marine-safe (RCM) paper-based flexible packaging flexible packaging. The startup combines water-soluble polymer with high-barrier paper in a patented process to create a flexible packaging material.

The resultant packaging is biodegradable and does not produce microplastics. It also features a gas barrier, water vapor transmission rate (WVTR) barrier, and puncture resistance, and produces the maximum amount of fiber while repulping.

Fam Ti manufactures Flexible Packaging Films

Canadian startup Fam Ti provides biaxially oriented polypropylene (BOPP) films, biaxially oriented polyethylene terephthalate (BOPET) films, metalized films, and PET resin for modular packaging.

The company’s Hi-Res metalizing machine ensures uniform deposition of aluminum on the film substrates and uniform barrier properties in the 5-layer BOPP films. The in-line coating system further provides various types of coatings for improved ink anchorage and metal adhesion in BOPET films.

A thin layer of aluminum deposition on the BOPP and BOPET films converts them into metalized films, which improves shelf life. The startup also utilizes optical density levels to measure metal deposition and produce different barrier levels. The coated films offer protection from moisture, oxygen, and chemicals, and come with improved optical and mechanical properties.

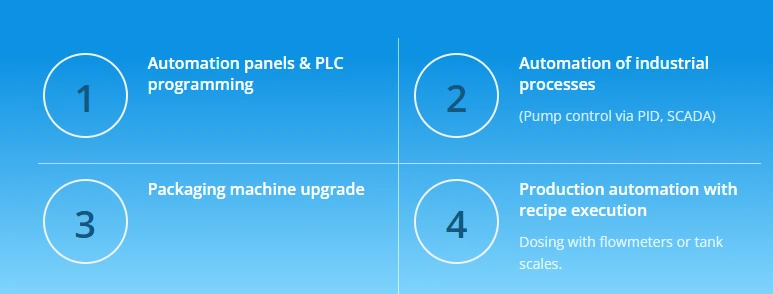

2. Packaging Automation

Advanced robotics is the key technology for automating packaging. Robotics in packaging lines optimize speed, and precision, and reduce human errors, allowing for high-velocity packaging with minimal defects. Operators employ robots capable of pick and place operations, palletizing and depalletizing, case packing, and unpacking in the packaging operations.

That is why approximately 67% of manufacturing facilities report heavy automation in end-of-line packaging processes.

Computer vision additionally assists in inspecting packaging defects and errors, verifying label placement, and guiding robotic systems for precise handling. Automated guided vehicles (AGV) and collaborative robots (cobots) further automate warehouse operations like product transportation and placement.

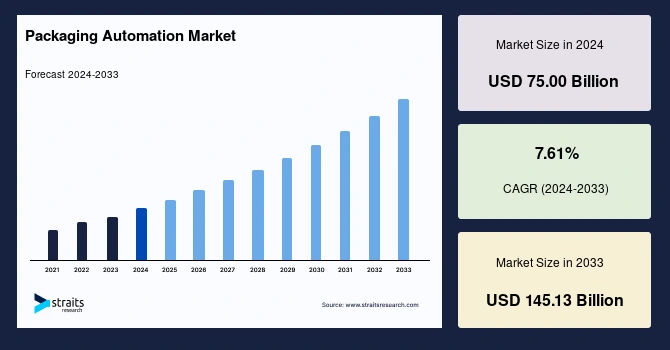

The global packaging automation market size is projected to reach USD 145.13 billion by 2033, growing at a CAGR of 7.61% during the forecast period of 2025-2033.

Credit: Straits Research

EMMETRON offers an Automated Liquid Packaging System

Greek startup EMMETRON manufactures packaging automation equipment. The startup’s semi-automatic and fully-automatic equipment are used for packaging lines in the liquid, chemical, and solid food industries.

The automatic packaging line includes a filling machine, a capping machine, labelers, automatic container feeding, and an automatic cap feeder. The company’s machines improve product hygiene, quality, and safety.

U2 ROBOTICS offers Flexible Robotic Packaging Solutions

French startup U2 ROBOTICS provides machines for packaging operations like product feeding, closing/sealing packages, labeling, palletizing, quality control, and more.

The machines include Flexilines and FlexiCapper among others. The Flexilines range consists of an automatic puck conveyor for bottle sorting, dosing, capping, and labeling. Flexicapper uses computer vision to recognize the closure position of the bottles and comes with 4 servo drive capping heads for capping cycle control.

Additionally, the machines feature cameras and remote maintenance systems for detecting and mitigating any errors instantly and remotely. These systems also record videos and alert workers if there is an error.

The startup uses OPC unified architecture (OPCUA) for connectivity and communication within the production line. It also uses packaging machine learning (Pack ML) and ILABO as the software platform to streamline packaging production. U2 ROBOTICS further employs a unique formula identifier (UFI) for ensuring quality products and correct product marking.

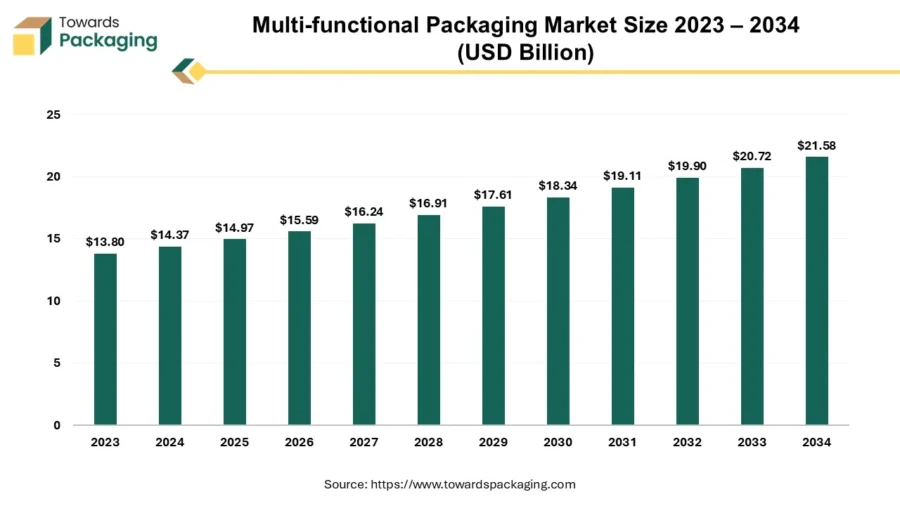

3. Functional Packaging

Functional packaging improves convenience, product safety, and shelf life.

Functional packaging often features easy usage methods like an easy tear option and reclosable zipper seal. They also carry properties that make them easy to handle and store.

Types of materials used in functional packaging include pouches, stick packs, corrugated cardboard boxes, reusable plastics, and blister packaging. Additionally, biopolymer-based films are used for lining packaging which allows the loading and releasing of active components in the product inside the packaging.

Popular examples of functional packaging include edible packaging like rice-based wrappers and water-soluble packaging. Such packages reduce waste and improve consumer experience.

The multi-functional packaging market is predicted to reach USD 21.58 billion by 2034, growing at a CAGR of 4.15% during the forecast period from 2025 to 2034.

Credit: Towards Packaging

Tastee Tape manufactures an Edible Packaging Film

US-based startup Tastee Tape provides an edible, sustainable packaging film. The plant-based film is allergen-free, paraben-free, microplastic-free, and chemical-free as well as home compostables.

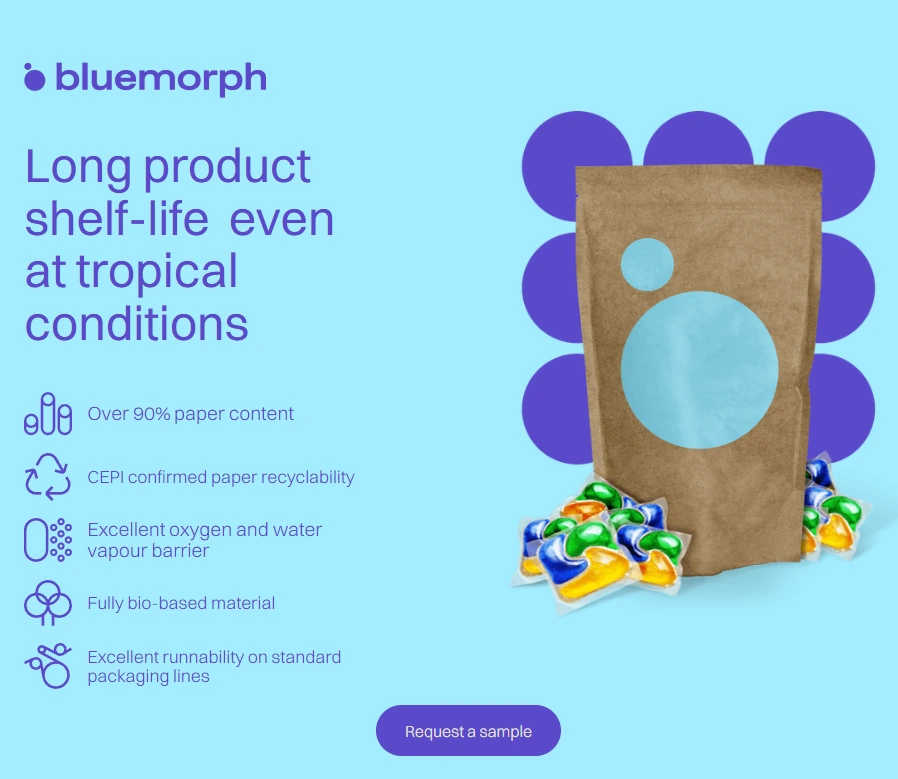

One.Five provides Shelf-life Extending and Transparent Packaging

German startup One.Five offers sustainable packaging, bluemorph, and clearwing, that extends product shelf life.

bluemorph ensures long product shelf-life in tropical conditions and is made of mostly paper content and bio-based material. It provides an oxygen and water vapor barrier and features CEPI-confirmed paper recyclability. Its clearwing is a transparent paper packaging with the same features as bluemorph.

The AI-based solution further ensures efficiency, cost-effectiveness, and sustainability in packaging by analyzing factors like CO2 offset, waste infrastructure, and barrier performance.

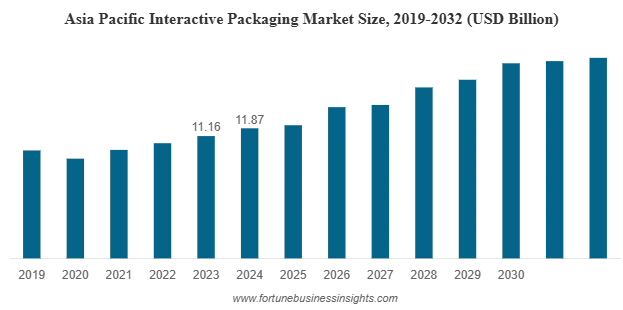

4. Interactive Packaging

Beyond customer engagement, interactive packaging increases brand awareness, and better product transparency.

Businesses use immersive technologies like augmented reality (AR), virtual reality (VR), and extended reality (XR) to provide product storytelling, visualization, and gamification. Brands like Lego, Loreal Paris, and Coca-Cola use immersive technologies.

While Lego uses AR to bring the racing tracks to life, L’oreal Paris uses it for virtual makeup try-ons. Coca-Cola released AR-mini games and VR soda during COVID-19 to strengthen the brand’s public image and keep consumer engagement stable.

Further, QR-enables packaging provides customers with product information, promotions, rewards, recipes, and tutorials.

Near field communication (NFC)-embedded packaging also offers product information and promotional news, authenticates product transparency, and ensures better customer engagement.

Radio frequency identification (RFID) on packages ensures real-time tracking, improved inventory management, and product safety. Additionally, the packaging industry uses blockchain to ensure supply chain transparency and authentication.

The global interactive packaging market is projected to grow from USD 36.67 billion in 2025 to USD 50.76 billion by 2032, exhibiting a CAGR of 4.75% during the forecast period.

Credit: Fortune Business Insights

SeeGap develops a QR-based Solution for Consumer-Packaged Food

Irish startup SeeGap offers QR codes for FMCG/CPG packages to drive customer engagement. The product-specific QR codes provide insights about the customer journey and improve customer experience.

It also enhances product marketing opportunities. SeeGap uses QR codes to create a hyper-relevant digital world for the customer, which contains details about the products. It also solves customer queries and provides real-time SKU-specific feedback to businesses.

Askbud delivers Automated Customer Support

Canadian startup Askbud uses QR codes to streamline and automate customer support. The QR codes are connected to AI assistants, which answer the questions. The AI assistants learn about the business and deliver precise responses.

Scanning the QR codes generates responses using information retrieval, compilation, summarization, and process review. Using the QR codes, customers also access a smart ticketing system.

The QR solution also comes with an analytics dashboard that businesses use to get actionable insights like performance tracking, question analysis, and opportunity discovery. It is suitable for product packaging, flyers, and door tags as it provides instant support and product recommendations to the users.

5. Active Packaging

Active packaging ensures extended shelf life of products, improved food safety and quality, reduced food waste, and increased organoleptic properties. Such packages contain active materials that interact with the products to maintain quality.

For instance, oxygen scavengers inside packaging remove or decrease oxygen content to inhibit microbial growth. Similarly, ethylene scavengers absorb ethylene, and moisture absorbers control the moisture content of the packaged material.

Active packaging also includes antimicrobial agents and carbon dioxide emitters/absorbers to maintain the quality of packaged products. Researchers are developing nanotech-based antimicrobial agents, antioxidants, and bio-based materials for active packaging. The nanomaterials-based packaging is useful for industries like pharmaceuticals, food, beverage, beauty, and cosmetics.

Additionally, integrating self-healing polymers within the packaging extends the life of packaging and reduces waste.

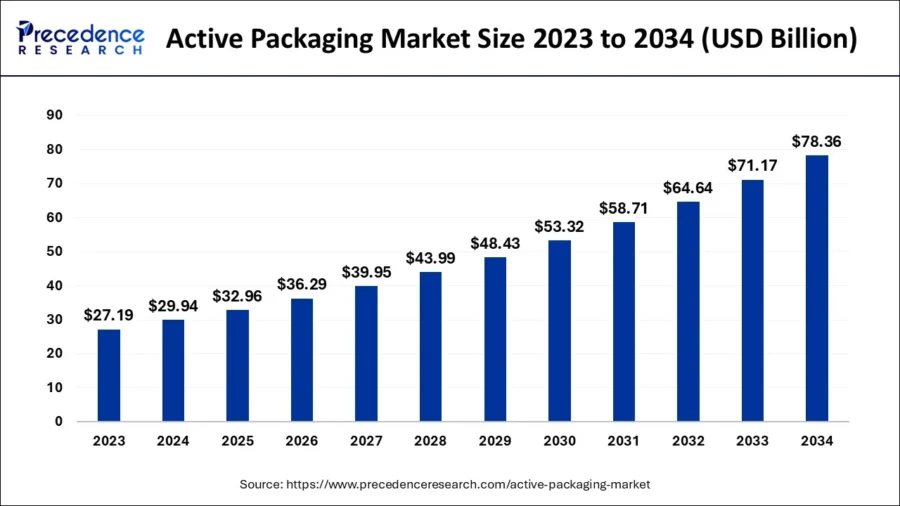

The global active packaging market size is anticipated to reach around USD 78.36 billion by 2034, expanding at a CAGR of 10.10% from 2024 to 2034.

Credit: Precedence Research

FreshTrack Tech develops Smart Colorimetric Films

Canadian startup FrashTrack Tech offers smart colorimetric sensing films for monitoring shrimp freshness. The startup utilizes biocompatible polyvinyl alcohol (PVA) and dyes from Arnebia euchroma to make the packaging. The antimicrobial and antioxidant properties of Arnebia euchroma preserve product quality.

Further, the film changes color to indicate the freshness and the chances of spoilage of the packed shrimp. This addresses the issues related to expired packaging and anthocyanin leaks.

Proteme manufactures a Shelf-Life Extending Food Coating

French startup Proteme provides a shelf-life-extending coating, Prosane. The coating is antimicrobial, natural, and biodegradable, and is used to wrap fruits and vegetables.

Prosane limits the interaction of water and oxygen from the outside to slow down the maturation of the product. The coating is edible, transparent, tasteless, and odorless.

Arborists, agricultural cooperatives, and market gardeners use it as an alternative to post-harvest phytosanitary products.

6. Biodegradable Packaging

Biodegradable packages reduce carbon footprint, increase resource conservation, enable faster decomposition, and lower waste production.

Currently, biodegradable packages are manufactured using materials that improve the soil health after decomposing. The materials include polylactic acid (PLA), cellulose-based films, mushroom packaging, seaweed-based materials, nanocellulose, and more.

For instance, Panasonic developed a cellulose fiber molding material that is fully marine biodegradable. Additionally, US-based startup PHAXTEC produces natural PHA biopolymers that are biodegradable in soil, fresh, and saltwater, as well as biocompatible and bioabsorbable.

Extrusion processing is a scalable technology for creating biodegradable packaging. Other methods of producing biodegradable packaging include injection molding, blow molding, additive manufacturing, nanocomposite technology, and biodegradable ink.

These methods improve barrier properties, mechanical strength, and thermal stability of the packaging along with improving sustainability. They also allow the use of a variety of biodegradable materials for manufacturing packaging.

Small-format packaging like sachets, coffee pod lids, and fruit stickers typically end up in landfills due to their size and mixed materials. Companies use compostable materials to produce these small format items for improving recyclability and waste management.

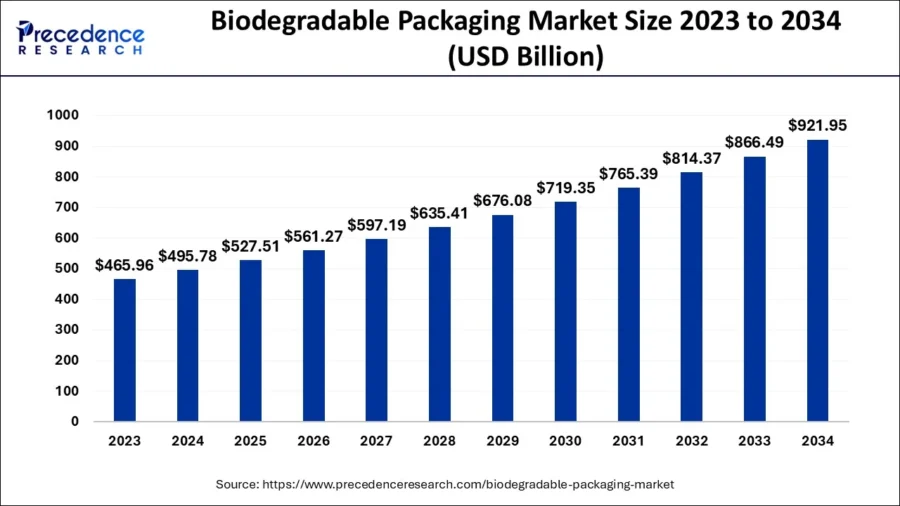

The global biodegradable packaging market is predicted to surpass USD 921.95 billion by 2034, representing a CAGR of 6.40% between 2024 and 2034.

Credit: Precedence Research

S.Lab designs Plant-based Biodegradable Packaging

Estonian startup S.Lab provides biodegradable, customized packaging solutions to replace styrofoam packaging. The startup utilizes agricultural waste, chitin, plant stems, and mushroom roots as raw materials and employs computer vision to make the packaging.

The packaging is waterproof, fire-resistant, and soundproof. S.Lab also uses an automated closed-loop system to reuse water and raw material waste from the production cycle. Further, the packaging leaves significantly less carbon footprint, takes less time to compost, and turns into soil fertilizer at its end of life.

The Sustainable Agave Company manufactures Agave-based Biodegradable Packaging

Canadian startup The Sustainable Agave Company produces packaging from upscaled agave to replace single-use packaging.

The startup produces proprietary agave-based resin. Various industries use this resin and employ thermoforming or injection molding to create consumer goods packaging, cosmetic packaging, barware including straws, and more.

7. Reusable and Returnable Packaging

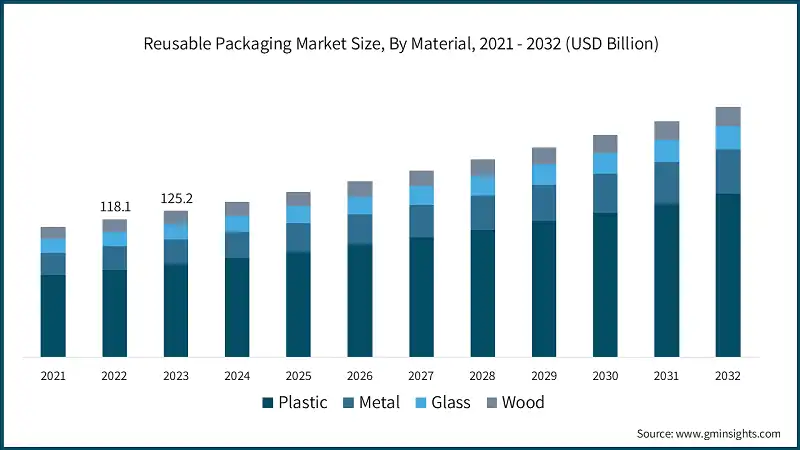

Reusable and returnable packaging ensures economic efficiency for business holders and mitigates the climate change crisis by decreasing the carbon footprint left by the packaging industry. Such packages use steel, wood, polypropylene sheets, recycled polyethylene terephthalate (rPET), and more as raw materials.

Returnable and reusable packages also integrate tracking technologies like RFID, IoT sensors, or NFC. These technologies ensure efficient inventory management, and supply chain visibility, and improve customer experience by simplifying package tracking for return and reuse.

Packaging companies also use hybrid IoT solutions along with Bluetooth low energy (BLE) and Wi-Fi for tracking the packages. Smart packages further incorporate sensors and microelectronics to monitor conditions within the reusable packaging. Personalization techniques like 3D printing and additive manufacturing additionally allow the customization of reusable containers.

Reusable packaging is creating a USD 10 billion economic opportunity and is a means to end plastic pollution.

Moreover, IFCO SmartCycle is improving reusable packaging containers (RPCs) by reducing the average carbon footprint of RPCs by an additional 10%. The IFCO RPCs produce up to 62% less CO2 compared to single-use packaging.

The global reusable packaging market size is estimated to grow at a CAGR of 6.1% from 2024 to 2032.

Credit: Global Market Insights

Thermo Carrier makes Temperature-Controlled Reusable Packaging

Dutch startup Thermo Carrier produces temperature-controlled, high-performance reusable packaging. Its products include cold chain transport boxes and off-grid boxes with real-time data and temperature-tracking applications.

The reusable cold chain transport boxes contain a phase-changing material (PCM) that absorbs heat and releases it later. This process maintains the required heat throughout transportation. It is suitable for applications like healthcare, transportation, and warehouse stocking.

The off-grid cooler combines vacuum insulation with PCM as well as functions without external power sources. It is made of recyclable material and is food-grade, antimicrobial, antibacterial, and shockproof. The off-grid cooler is appropriate for ice cream storage and outdoor storage like camping, boating, and hiking.

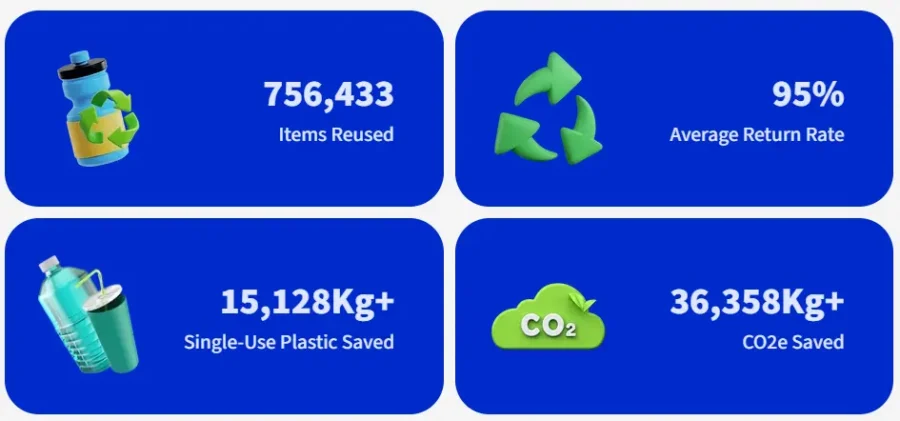

Circulayo develops a Consumer Engagement Platform for Returnable Packages

UK-based startup Circulayo builds a platform, Flow Platform, that traces packaging throughout its lifecycle to promote reusable packaging. The platform also promotes consumer engagement and eliminates single-use plastic waste. It comes with a tap-and-return feature that enables a digital deposit return scheme (DDR). Customers receive money for returning their packages using this scheme.

Businesses such as retail, food and drink, textile, and sports ventures use the platform to showcase environmental impact, share stories, and market promotions. They also use it to transform their reusable packages into smart reusable ones and monitor it throughout their journey.

Circulayo also develops AppNostic, which is a consumer engagement platform, and Flow Centre, which provides washing and renting services for reusable products.

8. Internet of Packaging

The need for real-time product tracking, improved customer engagement, and enhanced supply chain efficiency is driving innovations in the internet of packaging.

IoP leverages RFID, NFC, smart labels, QR codes, and sensors. IoT-enabled packaging tracks temperatures, humidity, and product freshness in real time. This is particularly essential for perishable and pharmaceutical goods. IoP also allows real-time tracking and monitoring of products, improved supply chain visibility, better inventory management, and reduced instances of theft or loss. For example, companies using IoP solutions reported a 30% reduction in supply chain costs

IoP further improves customer engagement by providing details about product information and incorporating customized offers personalization.

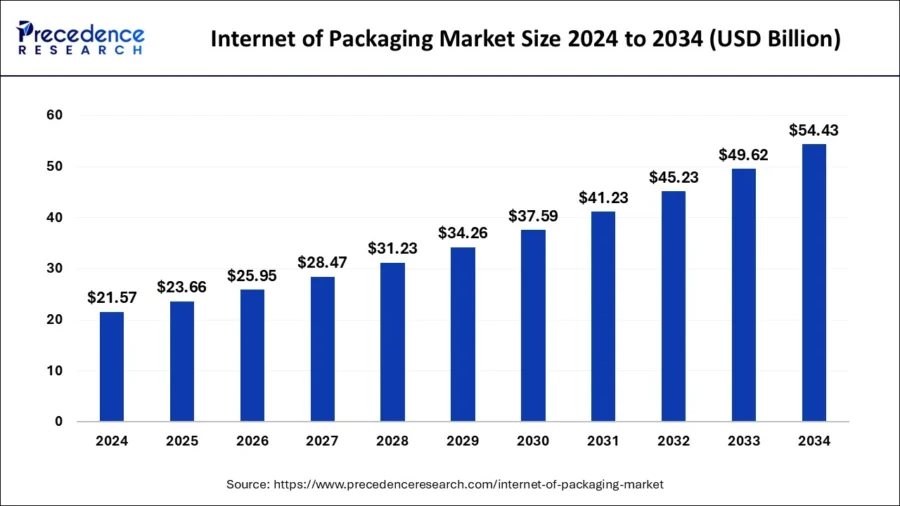

The global Internet of packaging market size is anticipated to reach around USD 54.43 billion by 2034, expanding at a CAGR of 9.70% from 2025 to 2034.

Credit: Precedence Research

Smartfill provides Smart Dispensers

UK-based startup Smartfill offers connected dispensers to eliminate single-use plastics and pollution. The dispensers come with a cloud-based platform for recording transaction and stock-level data. This data streamlines logistics and stock management and provides consumer insights for the brands.

These easy-to-use IoT-based dispensers are useful for refilling shampoo and washing powder, modern retail inventory control, and more. They increase margins for businesses by reducing refilling operational costs.

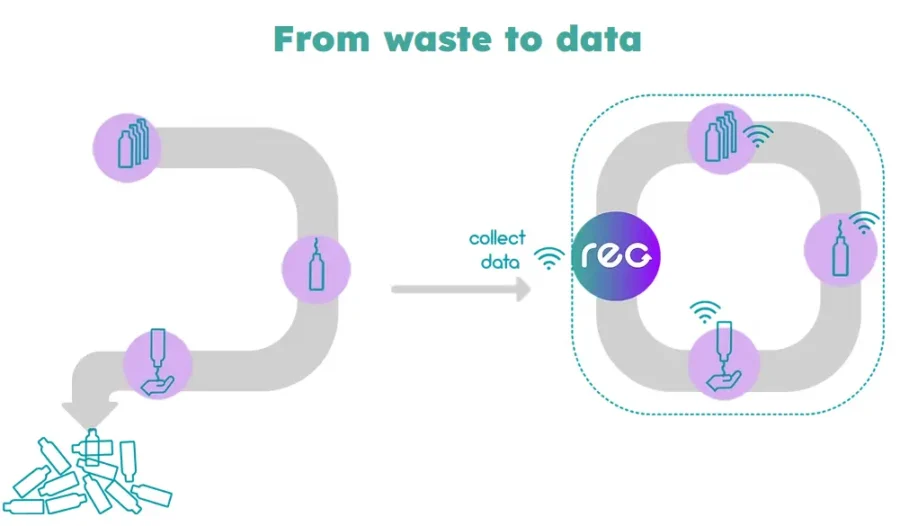

Reo manufactures IoT-enabled Circular Packaging

German startup Reo builds a circular packaging SaaS solution that digitizes rigid packaging and assists FMCG companies in adopting reusable packaging. The solution also promotes plastic waste recycling.

Using the technology, businesses reuse the packaging multiple times and reduce significant amounts of waste. Reo also offers an app plugin for customers to track the ecological footprint of the packaging and connect the consumers to the packaging life cycle.

9. Lightweight Packaging

Materials like polypropylene sheets, polyethylene terephthalate (PET), bioplastics, paper and cardboard, mycelium, and biopolymers are fit for lightweight packaging.

Cellulose caps and lightweight PET caps are reportedly reducing material usage and CO2 emissions by optimizing storage, shipping processes, and transportation. Lightweight packaging also reduces the number of shipments required as the packaging is easy to carry and store.

Almost 15% of the businessmen reported an increase in efficiency after switching to lightweight packaging.

Industries like e-commerce, retail, food and beverages, and personal care use lightweight packaging for efficient packing and shipping, transportation, and customer convenience.

Aerogel, a lightweight material, is ideal for packaging sensitive electronic devices and fragile items. These materials offer superior protection while minimizing weight.

The global lightweight packaging market size is expected to reach USD 215.39 billion by 2034, at a CAGR of 8.04% during the forecast period 2025 – 2034.

Ventek Solutions designs Shape Molded Foam Components

US-based startup Ventek Solutions manufactures engineered shape molded foam components, protective packaging, and multi-layered assembly solutions. The molded components include expanded polystyrene (EPS), expanded polypropylene (EPP), and expanded polyethylene (EPE), among other materials.

Ventek Solutions uses processes like shape molding, insert molding, die cutting, wire cutting, and CNC machining to produce these components. The molded foam components provide a thermal barrier, absorb energy during impact, and fill voids while decreasing weight.

Little Feet Packaging manufactures Plastic-Free Bubble Wrap

US-based startup Little Feet Packaging develops paper-based recyclable and compostable solutions. The startup uses recycled paper and starch-based adhesives to create its Pubble Wrap. It also uses bubble dome technology to form composite structures for cost-effective, strong, and environmentally friendly packaging.

The company also offers a proprietary dispensing system for perforating, cutting, and dispensing the Pubble Wrap according to customized order.

Further, the company’s other patented product, Pubble Polar, features an extra layer of thermal blocking paper for shipping frozen items. The startups also allow companies to implement on-site production of Pubble Wrap and Pubble Polar to save transportation costs.

10. 3D Printing

3D printing of packages enables low-volume production, rapid prototyping, on-demand production, and personalization. The use of materials like acrylonitrile butadiene styrene (ABS) and bioplastics is common in 3D printing.

The packaging industry utilizes technologies like fused deposition modeling (FDM), selective laser sintering (SLS), digital light processing (DLP), and more for producing packages.

FDM is mainly useful in functional packaging components, where it layers thermoplastic filaments to build the 3D packages. On the other hand, SLA utilizes a laser to cure and solidify liquid resin to create high-resolution packaging prototypes with smooth surfaces.

Additionally, SLS uses a laser to sinter powdered material, like nylon or polyamide, for durable and complex packaging structures. Using a binding agent and detailing agents, multi-jet fusion (MJF) creates precise and functional parts suitable for packaging components with high precision and accuracy. Polyjet technology further enables multi-material and multi-color printing.

These methods simplify package production for critical industries like healthcare, food and beverages, cosmetics, and pharma, where maintaining the quality of the contained product is essential.

For instance, Unilever stretches, blows, and molds bottles using 3D printing tools. It makes the bottles different from the other bottles and can be used in the market faster.

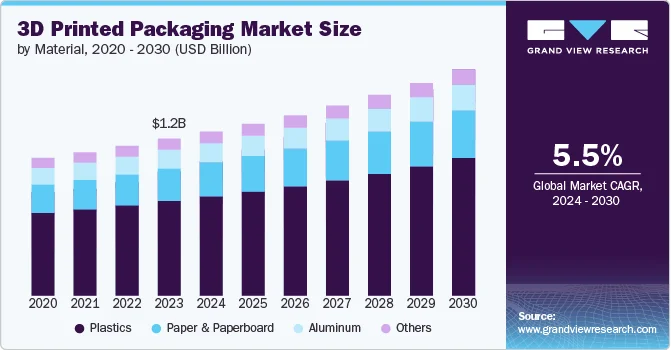

The global 3D printed packaging market is expected to grow at a CAGR of 5.5% from 2024 to 2030.

Credit: Grand View Research

QiTech simplifies Package Waste Recycling

German startup QiTech recycles plastic waste from industrial debris to develop reusable 3D printing filament.

The company places shredders in workplaces and laboratories based on their size and waste generation volume. The shredded plastics go through granulate extrusion in its laboratory, which has features like a pressure sensor and cloud connection.

These features allow remote monitoring and process adjustments of the process through an application.

Further, its cooling unit, Aipath, cools the granules at an even temperature and ensures smooth winding. DRE monitors the filament diameter during production, which is essential for high-quality prints. It is a modular system and compatible with various extrusion lines.

The Pro-Winder then winds and rewinds filaments as required. It also features intelligent speed control to monitor the tension on the filament and adjust the wind pressure. Qitech also provides recycled filament as a refill with reusable spools made from bottle caps.

Discover all Packaging Trends, Technologies & Startups

Waste management, climate crisis, and optimized logistics are a few factors driving the changes in the packaging industry. Technologies like blockchain, AI, IoT, and robotic automation will further support futuristic packaging like AI-driven predictive packaging design and voice and temperature-controlled packaging. The industry will also see advances in nanotechnology, hybrid substrates, algae derivations, and more.

The Packaging Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

![Packaging 4.0 : Top 9 Digital Transformation Technologies to Watch [2025]](https://www.startus-insights.com/wp-content/uploads/2025/02/Packaging-4.0-SharedImg-StartUs-Insights-noresize-420x236.webp)